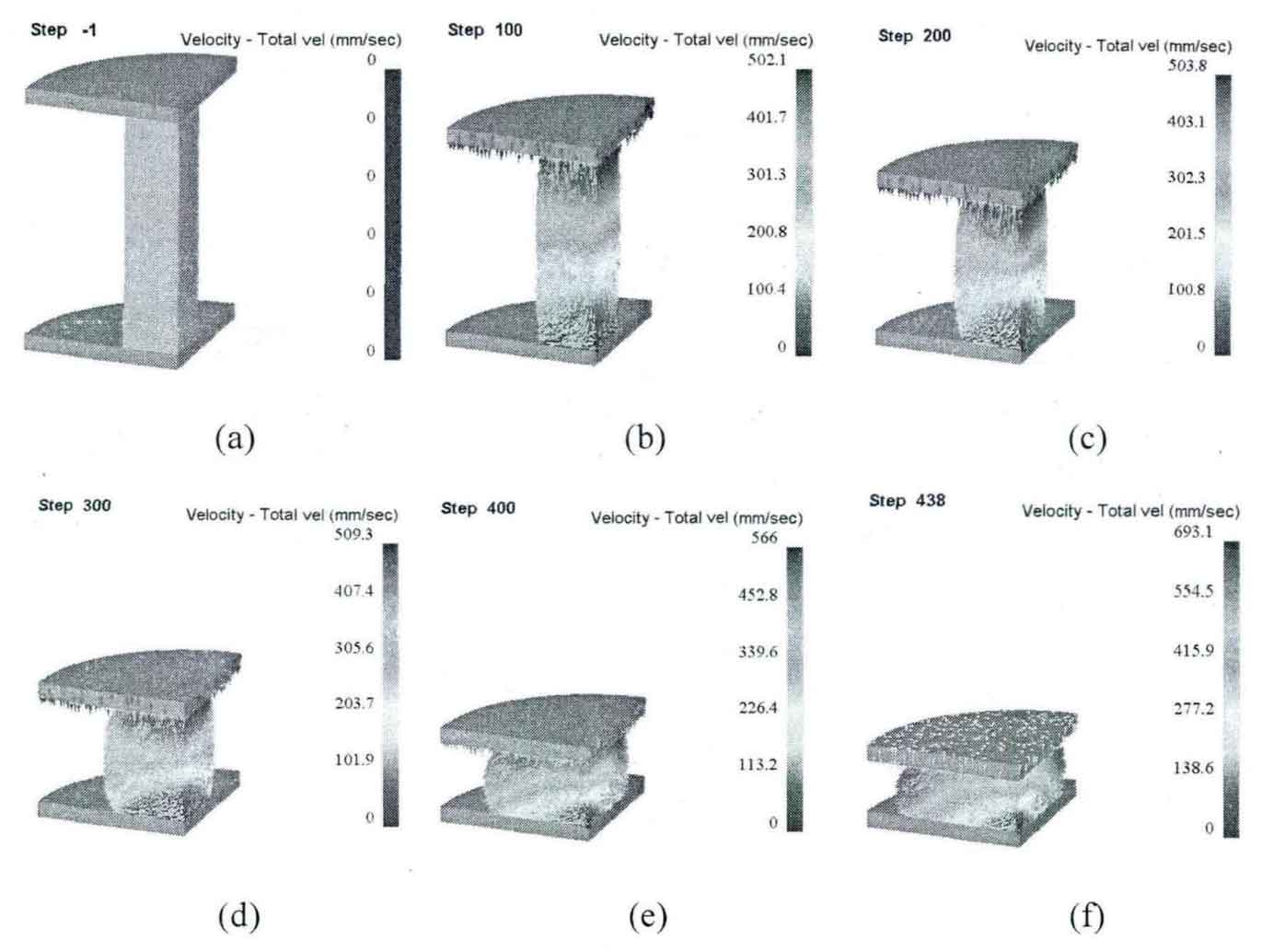

The metal velocity vector diagram of each stage in the upsetting process of spiral bevel gear blank is shown in Figure 1. Fig. 1 (a) is the metal flow velocity vector diagram at the beginning of the upsetting process of the spiral bevel gear blank, Fig. 1 (b) to Fig. 1 (E) are the metal flow velocity vector diagrams of the intermediate process, and Fig. 1 (f) is the metal flow velocity vector diagram at the completion of upsetting. The direction of arrow indicates the direction of metal flow velocity, and the magnitude of velocity is indicated by different colors. At the beginning of upsetting, the material near the upper anvil flows first, and the deformation is found first. The closer it is to the upper anvil, the faster the flow speed is. At the beginning, the flow speed is downward. With the upsetting process of the spiral bevel gear blank, the material gradually flows around until the upsetting of the spiral bevel gear blank is completed.

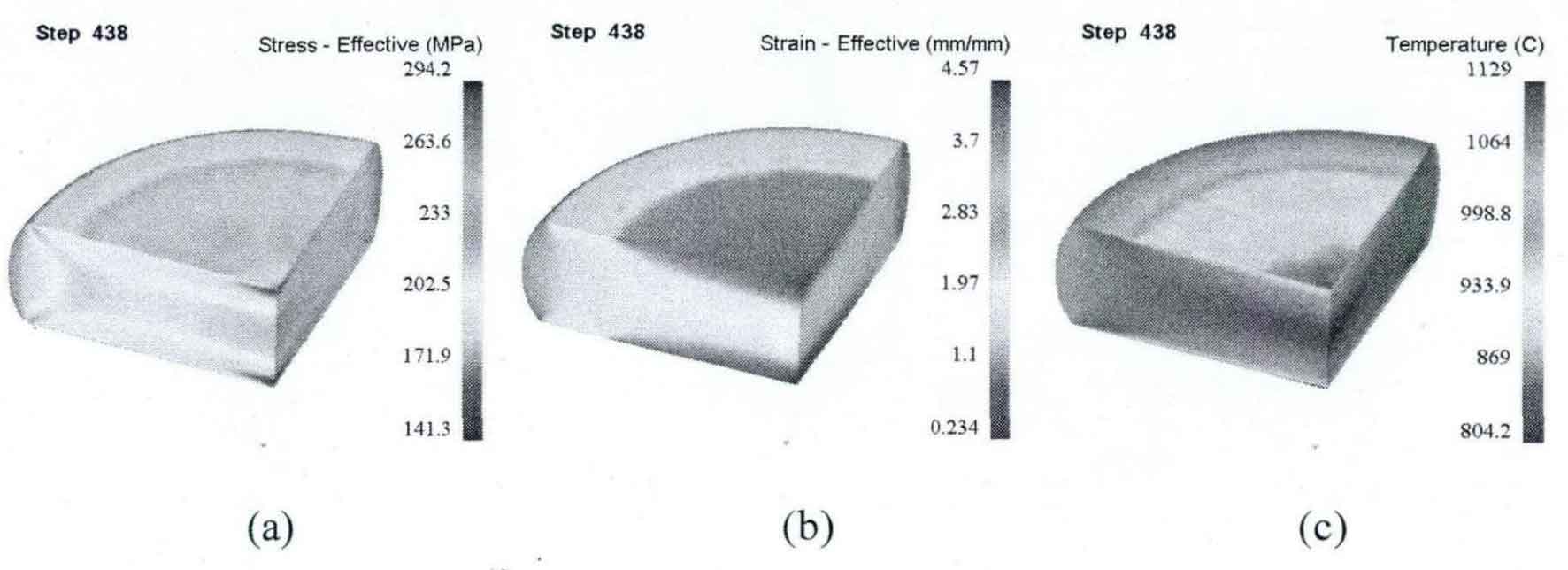

The equivalent stress-strain and temperature distribution of spiral bevel gear blank after upsetting are shown in Figure 2. After upsetting, the equivalent stress of spiral bevel gear blank is 140-290mpa, the equivalent strain is 0.23-4.57, and the temperature is 804-1129 ° C.