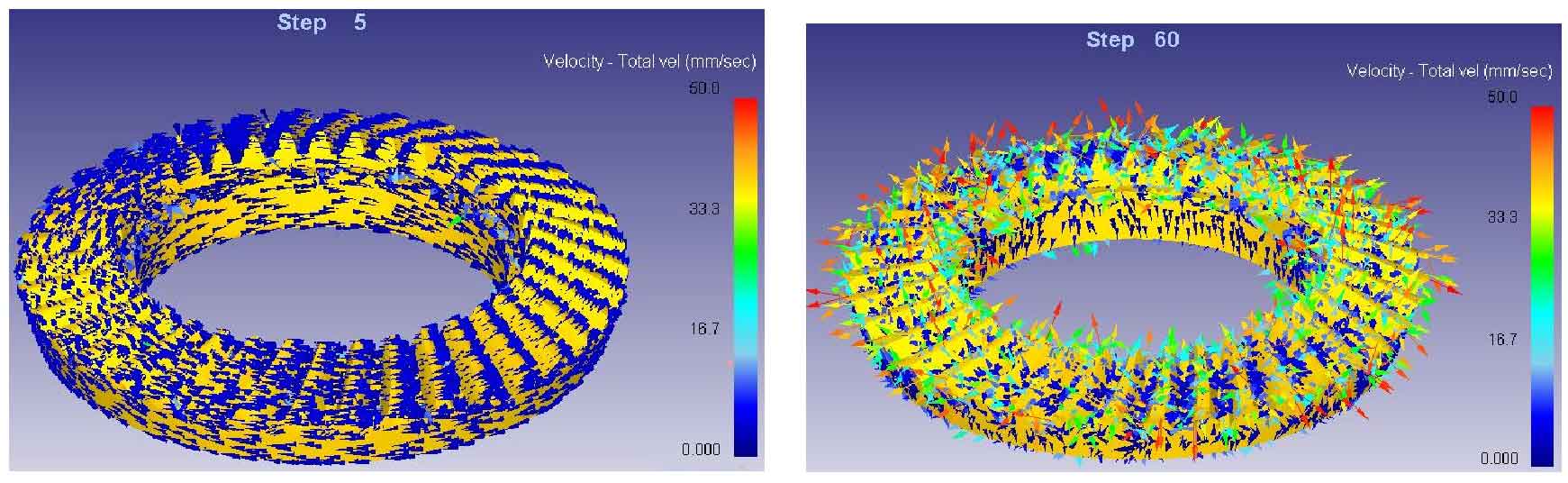

The figure shows the metal velocity distribution of different strokes in the cold finishing process of spiral bevel gear, in which figure (a) shows the metal velocity distribution when the stroke is 4 mm, and figure (b) shows the metal velocity distribution in the final step.

It can be seen from the figure that at the beginning of deformation, the metal flow velocity is small and flows in the direction of spiral bevel gear rotation. With the increase of stroke, the metal flow velocity becomes larger and larger, and the metal flow direction also changes to flow mainly from the small end of spiral bevel gear to the big end of gear along the direction of tooth profile, and the area with the largest flow velocity is mainly concentrated in the upper part of spiral bevel gear tooth profile.

It can be seen that in the process of cold finishing of spiral bevel gear, the part with large deformation is mainly concentrated in the tooth shape of spiral bevel gear, so the metal flow speed and deformation of the tooth shape of spiral bevel gear are large.