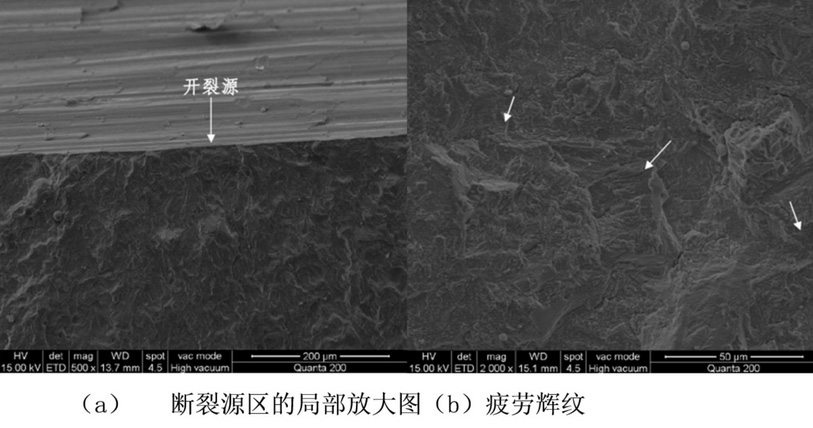

The fracture specimens were cut at the gear break and cleaned several times, then the fracture morphology was analyzed.The micro-morphology of the fracture at the gear break is shown in Figure 1, where:

(a) A local magnification of the source area of the fault.

(b) The figure shows the micro-morphology in the crack growth zone.

In the figure, the fracture source is located at the root of the tooth. No abnormal metallurgical quality defects and machining defects were found in this area through observation and analysis.A group of approximately parallel bending lines, similar to the beach line, i.e. fatigue striation, can be observed in the crack growth area, which further proves that the fracture of gears is fatigue fracture.It shows that the fracture failure of the sun wheel under alternating stress is also the fracture behavior caused by multiple accumulated damage of the gear, rather than the one-off fracture caused by accidental overload.The results agree with the previous stress analysis results.