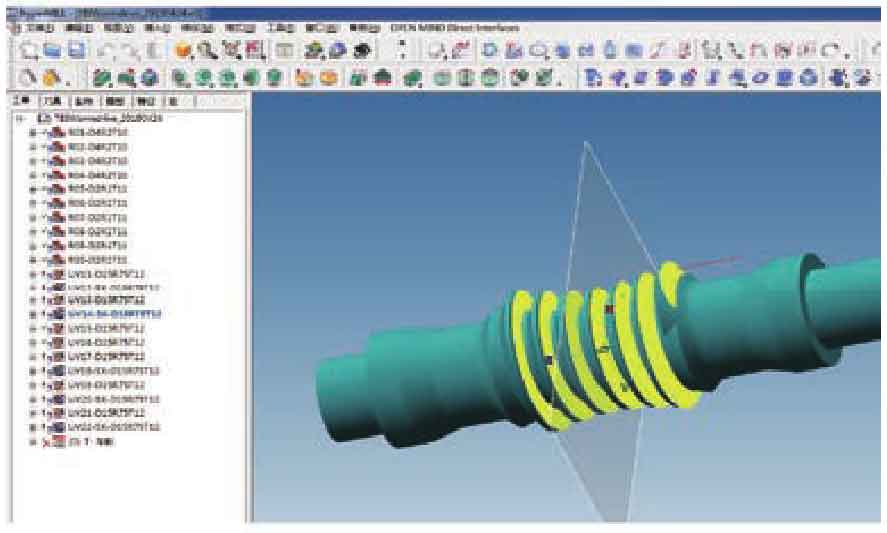

The accurate three-dimensional model of variable tooth thickness involute gear enveloping hourglass worm is established. In the five axis linkage CAM software hyperMILL, the tooth groove of hourglass worm is roughened with a 4 mm diameter end mill, as shown in Figure 1a, and the tooth surface is roughened with a 1.5 mm ball end mill, as shown in figure 1b, Finish milling the left and right tooth surfaces with 1.5 mm ball end milling cutter, as shown in Fig. 1c and D.

In dmu60 mono block five axis linkage vertical machining center, NC code generated by hyperMILL is used to mill the variable tooth thickness involute gear enveloping hourglass worm, as shown in Figure 2. The sample of hourglass worm machined by milling is shown in Fig. 3.