1. Introduction

Miter saw is a kind of portable power tool, which is widely used in the field of architectural decoration. This paper analyzes the factors that cause the noise of the miter gear in the three-stage gear transmission structure of the miter saw, and proposes corresponding solutions and improvement schemes.

2. Structure characteristics

The three-stage gear structure used in the miter saw can effectively improve the cutting ability and increase the function.

3. Cause analysis

3.1 Gear backlash

Gear backlash is one of the important factors that directly affect gear noise. The test results are shown in Table 1.

| Serial number | Prototype number | Miter Gear noise | Motor gear and large gear backlash(mm) | Meshing schematic diagram | Remarks |

|---|---|---|---|---|---|

| 1 | A1 – A5 | NG | 0.30 – 0.55 | – | – |

| 2 | B1 – B5 | NG | 0.00 – 0.10 | D | – |

| 3 | C1 – C5 | OK | 0.15 – 0.30 | – | – |

3.2 Gear installation

The size accuracy of miter gear installation is very important. The key dimensions that affect miter gear installation are shown in Figure 2, and the tolerance range after adjustment is shown in Table 2.

| Project | A1 | A2 | B1 | B2 | B3 | B4 | C1 | C2 | D1 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Adjusted tolerance | 0 / – 0.15 | 0 / – 0.11 | 0 / – 0.05 | + 0.1 / 0 | + 0.1 / 0 | – | 0 / – 0.11 | 0 / – 0.10 | 0 / – 0.12 | + 0.1 / 0 |

3.3 Important support parts

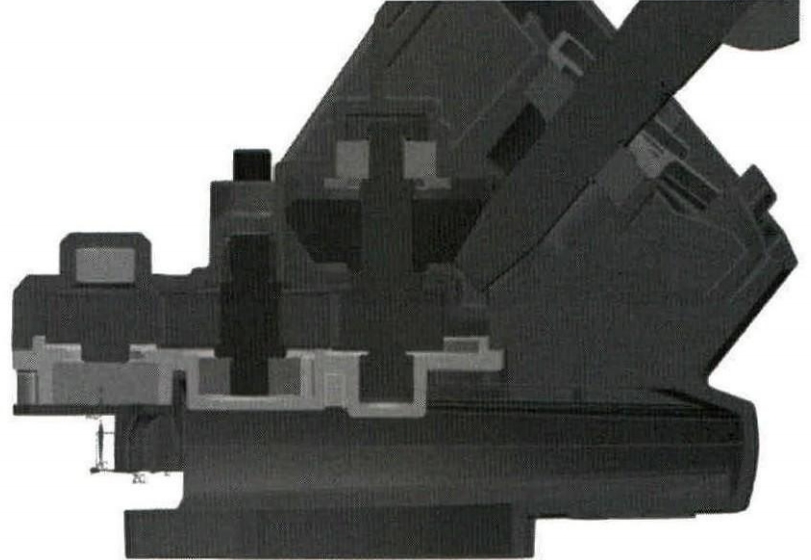

The thin wall, complex shape, and high-precision requirements of the gearbox cover of the miter saw can cause various defects and affect the miter gear noise. The gearbox cover is shown in Figure 3.

3.4 Gear damage

Gear damage, especially the damage on the convex surface and the burr residue on miter gear, can cause gear noise to varying degrees.

3.5 Gear accuracy

Gear machining accuracy is also a factor that directly affects miter gear noise, especially in the multi-stage gear transmission structure.

4. Improvement scheme

4.1 Gear backlash

- Adjust the backlash between the motor gear and the large bevel gear to 0.15mm – 0.25mm.

- Require miter gear processing department to effectively control miter gear quality according to the meshing method.

4.2 Gear installation

- Set appropriate tolerances, fully investigate the process capability of the equipment, and purchase new equipment when the process capability of the equipment is insufficient.

- Incorporate the listed dimensions as important dimensions into daily management and regularly analyze Ckp .

4.3 Important support parts

- Increase the circular arc angle design at the step difference.

- Increase the layout of reinforcing ribs as much as possible between the three-hole connections.

- Increase the requirements for the position tolerance of hole 1 and hole 3.

5. Conclusion

The noise of the miter gear in the three-stage gear transmission structure of the miter saw greatly affects the user experience and the service life of the product. It is necessary to eliminate and reduce such defects in the quality management process of power tool manufacturing enterprises.