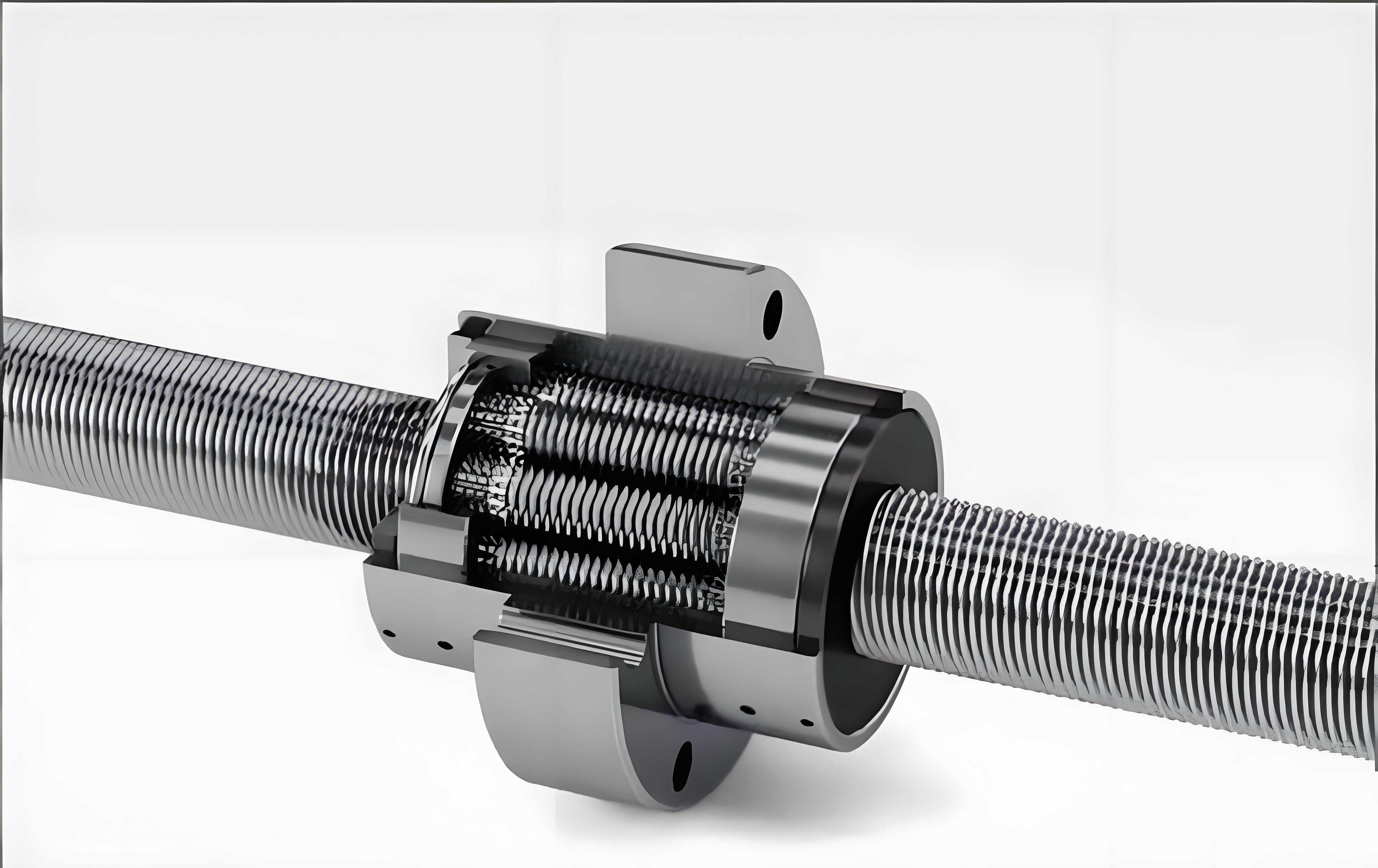

The planetary roller screw assembly (PRSA) is a high-precision mechanical actuator that converts rotary motion into linear motion, or vice versa, offering superior load capacity, stiffness, and longevity compared to its ball screw counterparts. Its unique design, comprising a central screw, multiple encircling planetary roller screws, and a nut, makes it indispensable in demanding applications such as aerospace actuation, heavy-duty machinery, and robotics. A critical aspect governing the performance, fatigue life, and reliability of any planetary roller screw assembly is the distribution of load across its engaged threads. Uneven load sharing can lead to premature wear, reduced stiffness, and eventual failure of the most heavily loaded threads.

Traditional analyses of load distribution within a planetary roller screw assembly often treat the rollers as simple axially loaded members, assuming the contact forces from the screw and nut threads are symmetric about the roller’s central axis. However, this assumption overlooks a crucial geometric reality. Due to axial clearance and manufacturing tolerances, the points of contact between a planetary roller screw and the screw threads are not diametrically opposite to its contacts with the nut threads. This misalignment results in axial contact forces that are eccentric relative to the roller’s central axis. These eccentric forces induce bending moments along the length of the planetary roller screw, causing it to deflect. This bending deformation, superimposed on axial tensile/compressive deformation, alters the relative axial displacements at each thread contact point, thereby influencing the final load distribution. Neglecting this effect can lead to an inaccurate and overly optimistic prediction of load uniformity. This article presents a comprehensive analytical model for calculating the thread load distribution in a planetary roller screw assembly that explicitly accounts for the bending deformation of the rollers.

Mechanism of Roller Bending in the Planetary Roller Screw Assembly

To understand the bending mechanism, we first examine the contact geometry on a single planetary roller screw. The contact points with the nut (\(P_{N}\)) are typically assumed to lie on the line connecting the centers of the nut and the roller. In contrast, the contact points with the screw (\(P_{S}\)) are offset due to the axial play necessary for assembly and lubrication. Figure 1 (refer to conceptual diagram above) illustrates this offset contact. In a simplified 2D cross-section, the contact force vectors at these points are not collinear with the roller’s axis.

When the planetary roller screw assembly is under an external axial load \(T\), each engaged thread tooth transmits a force. For the \(i\)-th thread pair, let \(F_{aSi}\) and \(F_{aNi}\) be the axial components of the contact forces acting on the roller from the screw and nut sides, respectively. These forces, applied at radial distances \(r_{Sr}\) and \(r_{Nr}\) from the roller’s centerline, create bending moments. The moment at any section due to the screw-side force \(F_{aSi}\) is \(M_{Si} = F_{aSi} \cdot r_{Sr}\). Similarly, the moment from the nut-side force is \(M_{Ni} = F_{aNi} \cdot r_{Nr}\). For a typical configuration, these moments are additive, causing the roller to bend in a consistent direction along its length.

We can model the planetary roller screw between two adjacent thread contact points as a beam segment of length \(L = P/2\), where \(P\) is the screw pitch, subjected to end moments and an axial force. The combined bending from all thread pairs results in a deformed shape. A key parameter for subsequent load distribution analysis is the rotation angle \(\theta\) of the roller’s cross-section at each thread contact point. Using principles from beam theory and superposition for a simply supported beam with end moments, the rotation angles at the screw-side (\(\theta_{Si}\)) and nut-side (\(\theta_{Ni}\)) contact points for the \(i\)-th segment can be derived:

$$ \theta_{Si} = \frac{M_{Si} \cdot L}{3EI} – \frac{M_{Ni} \cdot L}{6EI} $$

$$ \theta_{Ni} = \frac{M_{Ni} \cdot L}{3EI} – \frac{M_{Si} \cdot L}{6EI} $$

Here, \(E\) is the Young’s modulus of the roller material and \(I\) is its area moment of inertia. These rotation angles are critical for calculating the axial displacement component caused purely by bending.

Stress Analysis and Axial Displacement due to Combined Loading

Within the planetary roller screw assembly, a segment of the roller between two thread contacts is under a state of combined loading: axial tension/compression and biaxial bending (bending about two perpendicular axes). Consider the roller segment between the \(i\)-th screw contact point and the \(i\)-th nut contact point, separated by half a pitch (\(P/2\)). Let the axial coordinate along the roller be \(z\), with \(z=0\) at the screw contact and \(z=P/2\) at the nut contact.

The internal axial force in the segment is \(F_i\). The bending moments at a cross-section located at \(z=a\) are caused by the eccentric forces \(F_{aSi}\) and \(F_{aNi}\). Resolving the screw-side force into components \(F_{aSix}\) and \(F_{aSiy}\) in the roller’s coordinate system, the moments about the x and y axes (\(M_x\) and \(M_y\)) are:

$$ M_x(a) = \frac{(F_{aSiy} \cdot y_{Sr} – F_{aNi} \cdot y_{Nr}) \cdot a}{P/2} + F_{aSiy} \cdot y_{Sr} $$

$$ M_y(a) = \frac{F_{aSix} \cdot x_{Sr} \cdot a}{P/2} + F_{aSix} \cdot x_{Sr} $$

The total normal stress \(\sigma\) at any point \((x, y)\) on this cross-section is the sum of stress due to axial load and biaxial bending:

$$ \sigma(x, y, a) = \frac{F_i}{A_r} + \frac{M_x(a) \cdot y}{I_x} + \frac{M_y(a) \cdot x}{I_y} $$

where \(A_r\) is the cross-sectional area of the planetary roller screw, and \(I_x = I_y = I\) for a circular cross-section. The neutral axis is defined by the set of points where \(\sigma = 0\). Setting the equation to zero yields the linear equation for the neutral axis at a given section \(z=a\):

$$ \frac{F_i}{A_r} + \left( \frac{(F_{aSiy} y_{Sr} – F_{aNi} y_{Nr}) a}{P/2} + F_{aSiy} y_{Sr} \right) \frac{y}{I} + \left( \frac{F_{aSix} x_{Sr} a}{P/2} + F_{aSix} x_{Sr} \right) \frac{x}{I} = 0 $$

This axis does not pass through the centroid of the circular cross-section. The distance from a thread contact point (e.g., \(P_{Si}\) with coordinates \((x_{Sr}, y_{Sr})\)) to the neutral axis, denoted as \(t_{Si}\), can be calculated using the formula for the distance from a point to a line. The rotation angle \(\theta_{Si}\) at this point, derived earlier, represents the tilt of the cross-section. The axial displacement \(\Delta_{Si}\) of the contact point \(P_{Si}\), caused solely by this bending-induced rotation, is approximately (for small angles):

$$ \Delta_{Si} = t_{Si} \cdot \theta_{Si} $$

Similarly, for the nut-side contact point \(P_{Ni}\), the axial displacement is \(\Delta_{Ni} = t_{Ni} \cdot \theta_{Ni}\). These \(\Delta\) terms are vital corrections that must be included in the overall deformation compatibility equations of the planetary roller screw assembly.

Comprehensive Load Distribution Model

To determine the load on each engaged thread in the planetary roller screw assembly, we establish a system of equations based on force equilibrium and deformation compatibility, now including terms for roller bending. We assume all rollers share the load equally and that deformations remain elastic.

1. Deformation Components: The total relative approach between the screw and nut at the \(i\)-th thread consists of several parts:

- Contact Deformation (\(\delta_i\)): The local Hertzian deformation at the thread contact interface. For a thread tooth, it can be expressed as \(\delta_i = C \cdot F_{ni}^{2/3}\), where \(C\) is a contact compliance parameter depending on the material and thread geometry, and \(F_{ni}\) is the normal force.

- Axial Deformation of Screw/Nut Shaft: The screw and nut elongate/compress as tapered columns under the cumulative axial load from the threads. The deformation between the \(i\)-th and \((i+1)\)-th threads is \(\Delta L_{shaft} = \frac{F_{axial,avg} \cdot P}{E A_{shaft}}\).

- Axial and Bending Deformation of the Roller: This is the most complex part. The axial deformation of the roller segment between thread contacts \(i\) and \(i+1\) includes pure axial strain and the bending-induced axial displacements at its ends. For the segment between screw-side contacts \(i\) and \(i+1\):

$$ \Delta L_{S\_roller}^{i} = \frac{(F_{aSi} + F_{aSi+1}) P}{4 E A_r} – (\Delta_{Si} + \Delta_{Si+1}) $$

The term \((\Delta_{Si} + \Delta_{Si+1})\) subtracts the axial shortening (or adds lengthening) caused by the bending curvature at the two ends of the segment.

2. Deformation Compatibility Equation: For consistent engagement, the sum of deformations on the load path through the screw, the roller, and the nut must be equal for all threads. Considering the deformation loop from the screw thread \(i\), through the roller, to the nut thread \(i\), and comparing it to the loop for thread \(i+1\), we obtain the compatibility condition. A simplified form governing the relationship between loads on adjacent threads is:

$$ \left( \frac{P}{E A_{screw}} + K_c \right) F_{aSi} – \left( \frac{P}{E A_{nut}} + K_c \right) F_{aNi} + \Delta_{Ni} – \Delta_{Si} = \text{Constant} $$

Where \(K_c\) represents the combined compliance from thread contact and roller axial compression, simplified here for illustration. The terms \(\Delta_{Ni}\) and \(\Delta_{Si}\) are the bending-induced displacements, which are functions of \(F_{aSi}\) and \(F_{aNi}\) themselves, making the system non-linear.

3. Force Equilibrium Equation: The sum of the axial components of all thread loads on the roller must balance. Assuming \(n\) engaged threads on one side of the roller:

$$ \sum_{i=1}^{n} F_{aSi} = \sum_{i=1}^{n} F_{aNi} = \frac{T}{N} $$

where \(T\) is the total external axial load on the planetary roller screw assembly, and \(N\) is the number of planetary roller screws.

The system of equations formed by the compatibility conditions (for \(i = 1\) to \(n-1\)) and the equilibrium conditions is solved iteratively to find the axial load on each screw-side and nut-side thread tooth, \(F_{aSi}\) and \(F_{aNi}\).

Calculation Example and Model Validation

To demonstrate the model, we analyze a planetary roller screw assembly with the geometric parameters listed in Table 1. The material is bearing steel (GCr15) with Elastic Modulus \(E = 212\) GPa and Poisson’s ratio \(\nu = 0.29\).

| Geometric Parameter | Screw | Roller | Nut |

|---|---|---|---|

| Pitch Diameter (mm) | 19.5 | 6.5 | 32.5 |

| Pitch, \(P\) (mm) | 0.4 | 0.4 | 0.4 |

| Number of Thread Starts | 5 | 1 | 5 |

| Number of Engaged Threads | — | 30 | — |

| Thread Profile Angle (°) | 45 | 45 | 45 |

Solving the non-linear system for a total axial load \(T = 20\) kN yields the load distribution per roller. The results, comparing the model with and without considering roller bending, are summarized conceptually below and shown in Figure 2. The load is normalized by the average thread load (\(F_{avg} = T/(N \cdot n)\)).

| Thread Position \(i\) (from fixed end) | Normalized Load (No Bending), \(F’_{Si}/F_{avg}\) | Normalized Load (With Bending), \(F_{Si}/F_{avg}\) | Difference, \(\Delta y = F_{Si}/F_{avg} – F’_{Si}/F_{avg}\) |

|---|---|---|---|

| 1 (Fixed End) | 1.25 | 1.32 | +0.07 |

| 2 | 1.18 | 1.23 | +0.05 |

| … | … | … | … |

| 15 (Middle) | 1.00 | 1.02 | +0.02 |

| … | … | … | … |

| 29 | 0.82 | 0.79 | -0.03 |

| 30 (Free End) | 0.75 | 0.71 | -0.04 |

Key Observation from Results: The load distribution remains trapezoidal, with the highest load on the thread closest to the fixed support (typically where the screw or nut is constrained). However, incorporating roller bending deformation increases the load on the heavily loaded threads near the fixed end and further decreases the load on the lightly loaded threads near the free end. This worsens the load unevenness, quantified by the ratio of maximum to minimum thread load. In this example, the load non-uniformity factor increases when bending is considered. This finding is crucial for accurate life prediction of the planetary roller screw assembly.

Parametric Influence of Roller Bending on Load Distribution

The impact of roller bending is not constant; it varies with the operating conditions and design parameters of the planetary roller screw assembly. We define \(\Delta y_i\) as the change in the normalized load for the \(i\)-th thread due to bending. The trend of the maximum \(\Delta y_i\) (usually at the first or last thread) with key parameters is analyzed below.

1. Effect of Axial Load \(T\): The bending moment in the planetary roller screw is directly proportional to the thread contact force. Therefore, as the external load \(T\) increases, the bending deformation becomes more significant, exacerbating its effect on load distribution.

| Total Axial Load, \(T\) (kN) | Max \(\Delta y_i\) (P=0.4mm) |

|---|---|

| 15 | 0.05 |

| 25 | 0.06 |

| 35 | 0.075 |

| 50 | 0.095 |

| 70 | 0.12 |

2. Effect of Pitch \(P\): The pitch directly determines the length \(L = P/2\) of the roller segment between thread contacts. Since the deflection of a beam under moment is proportional to the cube of its length (\(\delta \propto L^3\)), a larger pitch dramatically increases the roller’s susceptibility to bending.

| Pitch, \(P\) (mm) | Max \(\Delta y_i\) (T=20kN) |

|---|---|

| 0.6 | 0.10 |

| 0.8 | 0.18 |

| 1.0 | 0.28 |

| 1.2 | 0.40 |

| 1.4 | 0.55 |

3. Effect of Roller Elastic Modulus \(E_r\): The bending stiffness of the planetary roller screw is proportional to its Young’s modulus \(E\). A higher modulus material makes the roller stiffer, resisting bending deformation and thus mitigating its influence on load distribution.

| Roller Modulus, \(E_r\) (GPa) | Max \(\Delta y_i\) (T=20kN, P=0.4mm) |

|---|---|

| 160 | 0.08 |

| 200 | 0.06 |

| 212 (Ref) | 0.055 |

| 250 | 0.045 |

| 300 | 0.035 |

Conclusions

This analysis establishes a refined methodology for calculating thread load distribution in a planetary roller screw assembly by incorporating the often-neglected bending deformation of the rollers. The key findings are:

- Model Development: A comprehensive analytical model was developed that accounts for axial tension/compression, biaxial bending of the rollers, thread contact deformation, and shaft stretching. The model solves the non-linear system defined by deformation compatibility and force equilibrium equations.

- Impact of Bending: Roller bending deformation increases the non-uniformity of load sharing across the threads. It raises the load on the already heavily loaded threads near the fixed support and reduces it further on the lightly loaded threads, leading to a higher maximum load and a potentially reduced fatigue life for the planetary roller screw assembly.

- Parametric Sensitivity: The detrimental effect of roller bending on load distribution uniformity is magnified by increasing the axial operating load (\(T\)) and the thread pitch (\(P\)). Conversely, using a planetary roller screw material with a higher Young’s modulus (\(E\)) can effectively reduce this effect, promoting more even load sharing.

Therefore, for the accurate design and life assessment of high-performance planetary roller screw assembly systems, especially those operating under high loads or with large pitches, it is essential to consider the influence of roller bending in the load distribution analysis. This model provides a foundational tool for such advanced engineering evaluations. Future work could integrate this quasi-static model with dynamic analyses and explore the effects of thermal gradients and lubrication within the planetary roller screw assembly.