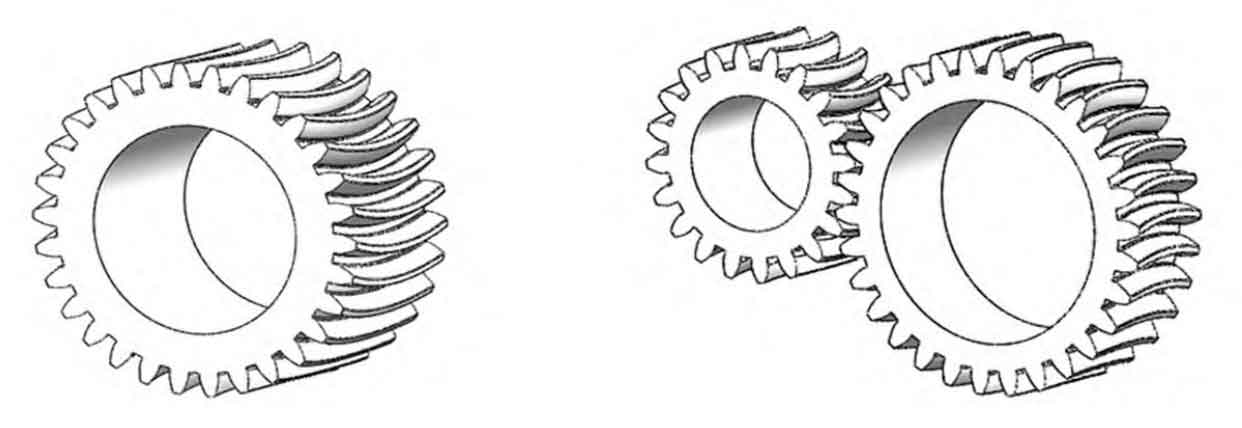

The basic parameters of circular tooth profile cylindrical gear pair are listed in the table. Based on the 3D modeling software SolidWorks, the following basic steps are followed: draw the base circle, tooth root circle, indexing circle, tooth top circle and involute according to the parameters; Then draw the end tooth profile and the middle section tooth profile of the circular tooth profile cylindrical gear, write the relevant program in Matlab to generate the space guide line, import the coordinates of the guide line discrete into several points into SolidWorks, and use the curve function to generate the space guide line; Because the tooth line of the circular tooth line cylindrical gear is of circular arc shape, only the rotation angle of each end face needs to be calculated when generating the model, and finally the lofting cutting, fillet and array commands can be executed according to the guide line to obtain the circular tooth line cylindrical gear model. As shown in Figure 1.

| Parameters | Value |

| Number of teeth z1/z2 | 20/30 |

| Modulus m/mm | 4 |

| Tooth width b/mm | 40 |

| Tooth line radius Rt/mm | 100 |

The tooth profile of any section parallel to the plane of the central axis of the involute circular tooth profile cylindrical gear is an involute tooth profile, the circumferential tooth thickness of the gear is also equal everywhere, and the curvature radius of the concave and convex surface of the gear is also equal, and the tooth profile is part of the circular arc. This tooth profile belongs to the standard tooth profile. A pair of circular arc tooth line cylindrical gears with equal pressure angle and modulus can mesh smoothly, and the tooth surface contact is line contact. This tooth profile can increase the contact area and overlap, and increase the service life of the gear. The model of the gear pair is shown in Figure 2.