In the driving process of electric vehicles, the gearbox is one of the main causes of vehicle noise. At this time, effective noise reduction for the gearbox is the key to realize the “silent mode” of vehicle noise. In the construction of automobile gearbox, the specific causes of noise are relatively diverse, among which the noise caused by the meshing of spur gears is the key reason. Based on this, it is quite necessary to conduct in-depth research on the subject of the research on the modification technology of spur gears in electric vehicle transmissions.

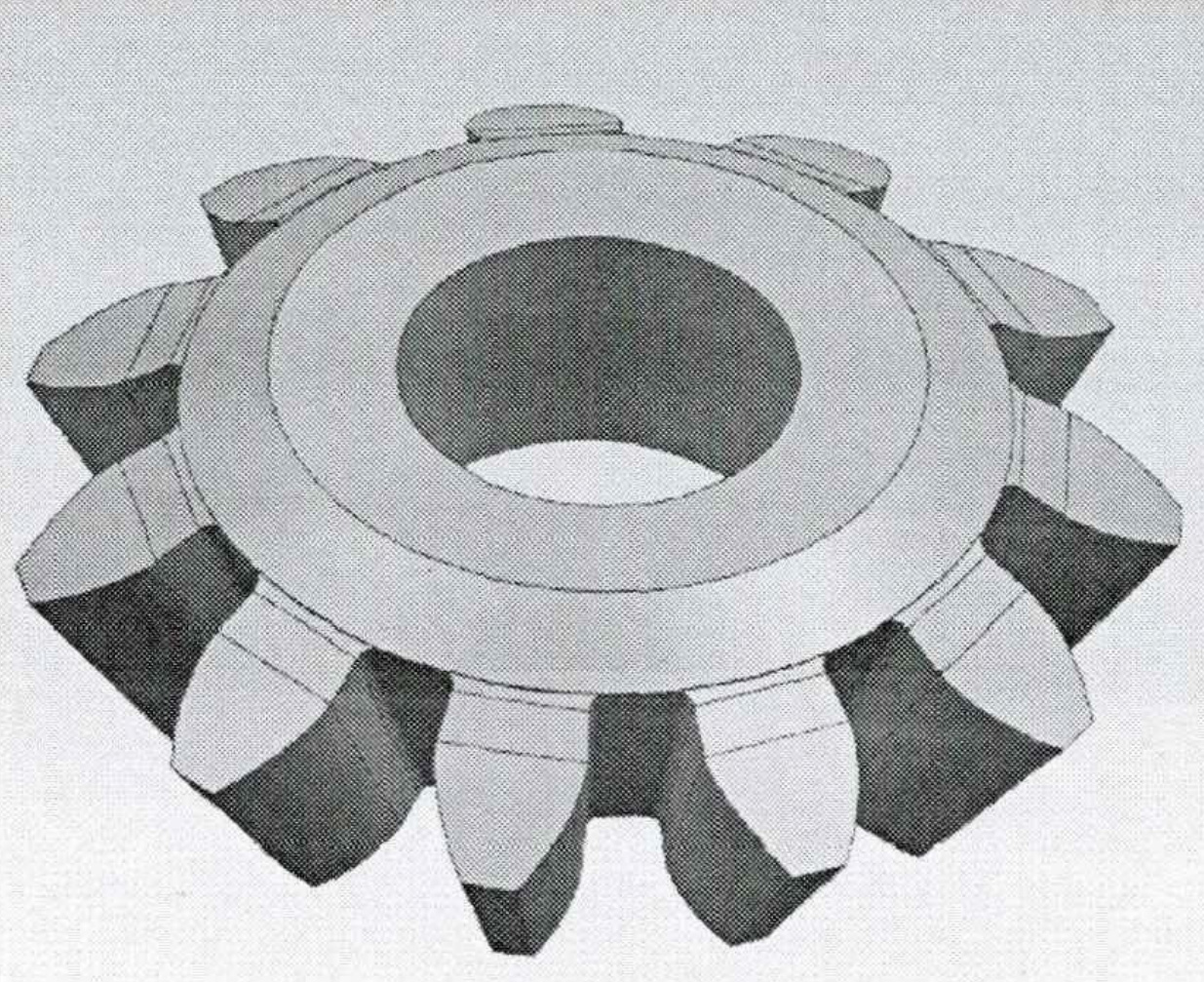

During the driving of the electric vehicle, when the paired involute spur gear meshing components are running, the single tooth and double tooth meshing work is completed alternately, and the actual load force of each spur gear will fluctuate, which will lead to the obvious mutation of the meshing load distribution of spur cylindrical gear in a short time. On this basis, the production error of spur gear and the elastic change of spur gear will cause the geometric interference problem of involute spur gear when the standard meshing work is carried out. At the same time, the elastic deformation of spur gear itself during the alternating change of spur gear components will seriously affect the meshing rotation of the next gear after a spur gear, Then, a pair of spur gears in the meshing process produce additional elastic deformation force, and finally form the meshing impact maintenance fault. In order to maintain and solve the vehicle noise problem caused by this meshing impact, the application of spur gear modification technology plays an important role. The application purpose of this technology is to dissolve the elastic deformation force when geometric interference occurs, so that the load force in the meshing process of spur gear is evenly distributed, and the stability of electric vehicle transmission spur gear operation is optimized, The modification technology of spur gear is the key manufacturing technology of domestic spur gear manufacturers.

Generally speaking, with the development of China’s economy, the national requirements for living comfort and environment are gradually rising, especially the environmental breaking force caused by sound pollution can not be ignored. Among them, the sound pollution to the environment includes the emergence of car noise. In order to effectively reduce this kind of harm, it is necessary to reduce the meshing impact of the transmission spur gear components in the automobile, so as to achieve the purpose of averaging the load surface distribution of spur gear. The research results show that the application of reasonable modification technology of spur gear in gearbox can effectively reduce the impact on the service life of spur gear due to the meshing process, minimize the probability of stress concentration friction, and finally achieve the purpose of uniform load on the area of spur gear.