1.Involute helical cylindrical gear defined by modulus

1) Use the common normal micrometer (or digital caliper) to measure the common normal length across K teeth and K + 1 teeth, that is, the measured value of the common normal length wk across K teeth and the common normal length wk + 1 across K + 1 teeth.

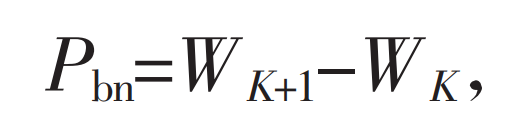

2) Find the base knot (base circle pitch) of involute helical cylindrical gear:

Where: PBN is the measured value of the measured gear base joint; Wk is the common normal length across K teeth; Wk + 1 is the common normal length across K + 1 teeth.

3)Pb=πMcos α, The normal modulus Mn of the measured gear and the normal pressure angle of the indexing circle can be obtained by checking the base pitch table α n。

2. Involute helical cylindrical gear defined by end face modulus MT (e.g. sendland tooth profile)

1) Measure the tooth profile dimension of the end face, and the method is the same as above to obtain the end face modulus MT of the gear to be measured;

2)Mt=Mn′/cos β。 Mn ‘is the calculation direction modulus of the measured gear; β Is the helix angle of the dividing circle.