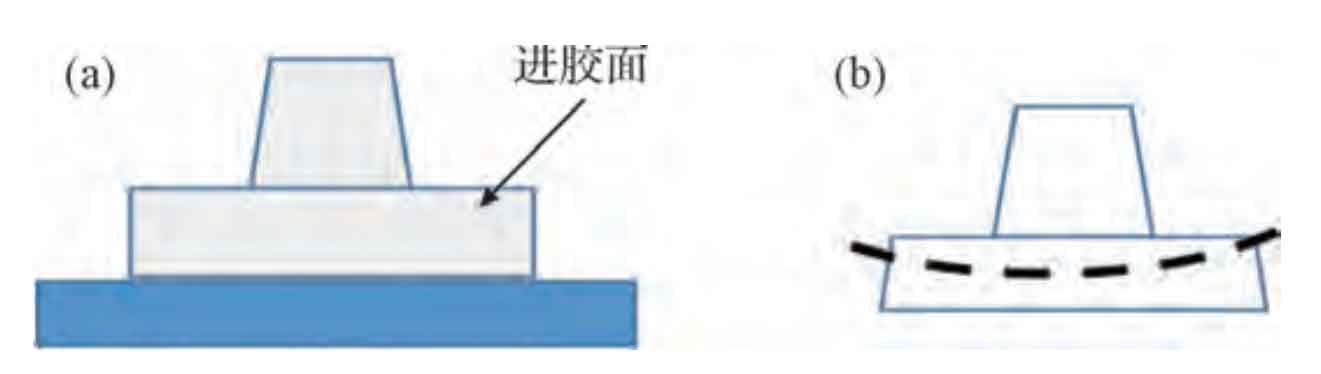

In the four sinters (1 280, 1 300, 1 320, 1 340 ° C) of the pilot experiment, the sintered products at 1 300 ° C showed good density and microstructure. When the temperature was more than 1 300 ° C, the surface appeared micro-melting and grain hypertrophy, so 1 300 ° C was selected as the optimal sintering temperature; It can be seen from the measurement results that the MIM spur gear products without mold compensation have the phenomenon of collapsing towards the center of the shaft sleeve (the outer diameter and the bottom diameter of the tooth at the end of the rubber feeding surface are too small, and the outer diameter and the bottom diameter of the tooth at the end of the ejector pin are too large, resulting in a large difference between the upper and lower sides of the common normal tooth thickness), which should be related to the powder shape, particle distribution and mold modeling design. Figure 1 (b) is a schematic diagram of geometric shape measurement of pilot test MIM spur gear products.

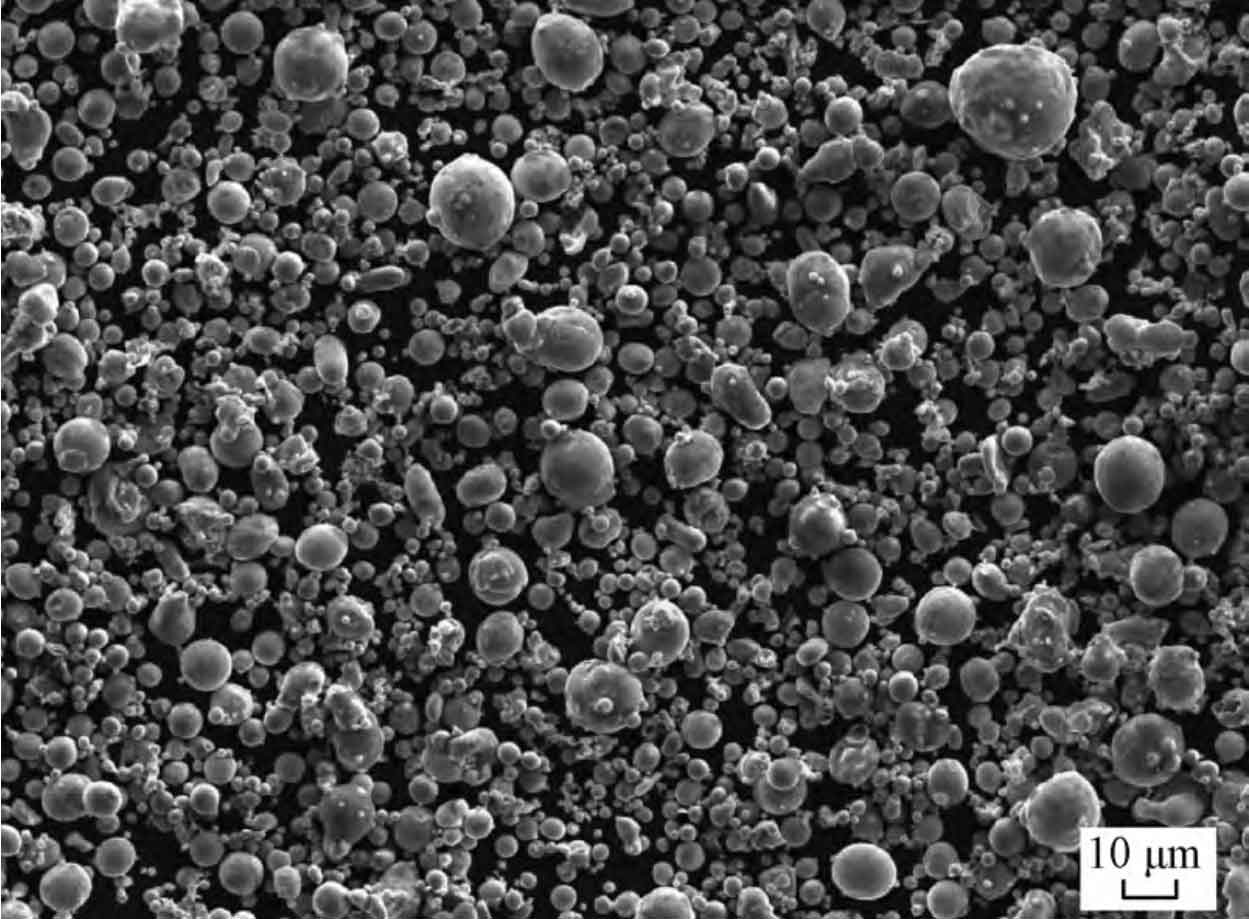

This phenomenon is very common in traditional plastic injection spur gears. The product shrinks and deforms after cooling due to the flesh thickness design such as glue reduction. Figure 2 shows the electron micrograph of the original powder provided by the feeding supplier. It can be seen from the figure that the high smoothness and sphericity of the water-air combined atomization powder may be the cause of poor conformal property, and the resulting deformation will lead to poor accuracy of the whole spur gear product.