Through multi-objective optimization design and simulation analysis of a single stage helical gear reducer, the following conclusions can be drawn.

1) Based on theoretical calculations, the difference in maximum bending stress between the wheel and pinion gear roots of the optimized front reducer is 21.3577 MPa, while the difference in maximum bending stress between the wheel and pinion gear roots designed using the localization method is 2.7393 MPa; Before optimization, the contact stress on the tooth surfaces of the wheel and pinion gears of the reducer was 720.9034MPa, while the contact stress on the tooth surfaces of the wheel and pinion gears designed using the optimization method in this article was 687.2090MPa, which was reduced by 33.6944MPa compared to before optimization.

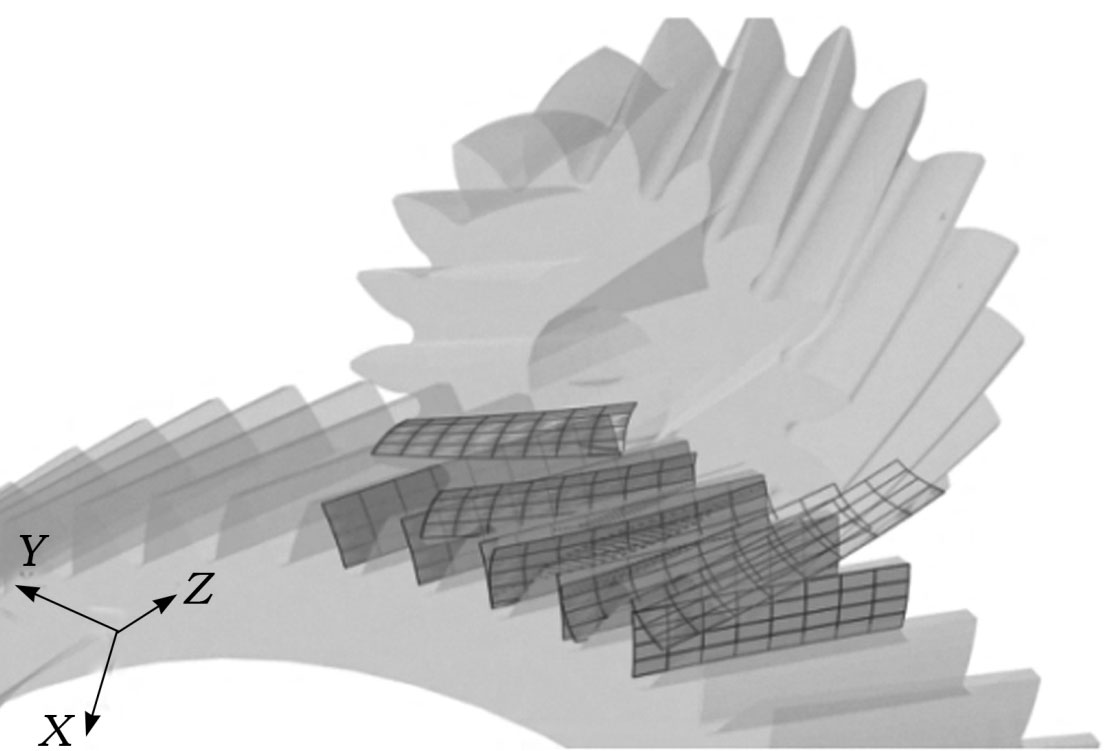

2) The simulation analysis is consistent with the theoretical calculation results, proving the correctness of the theoretical calculation. By using the MOPSO algorithm in this article for optimization design, the optimal solution set that meets the design requirements can be obtained. Based on actual engineering requirements, selecting the optimal solution that meets the design requirements can improve design efficiency and achieve good design results.