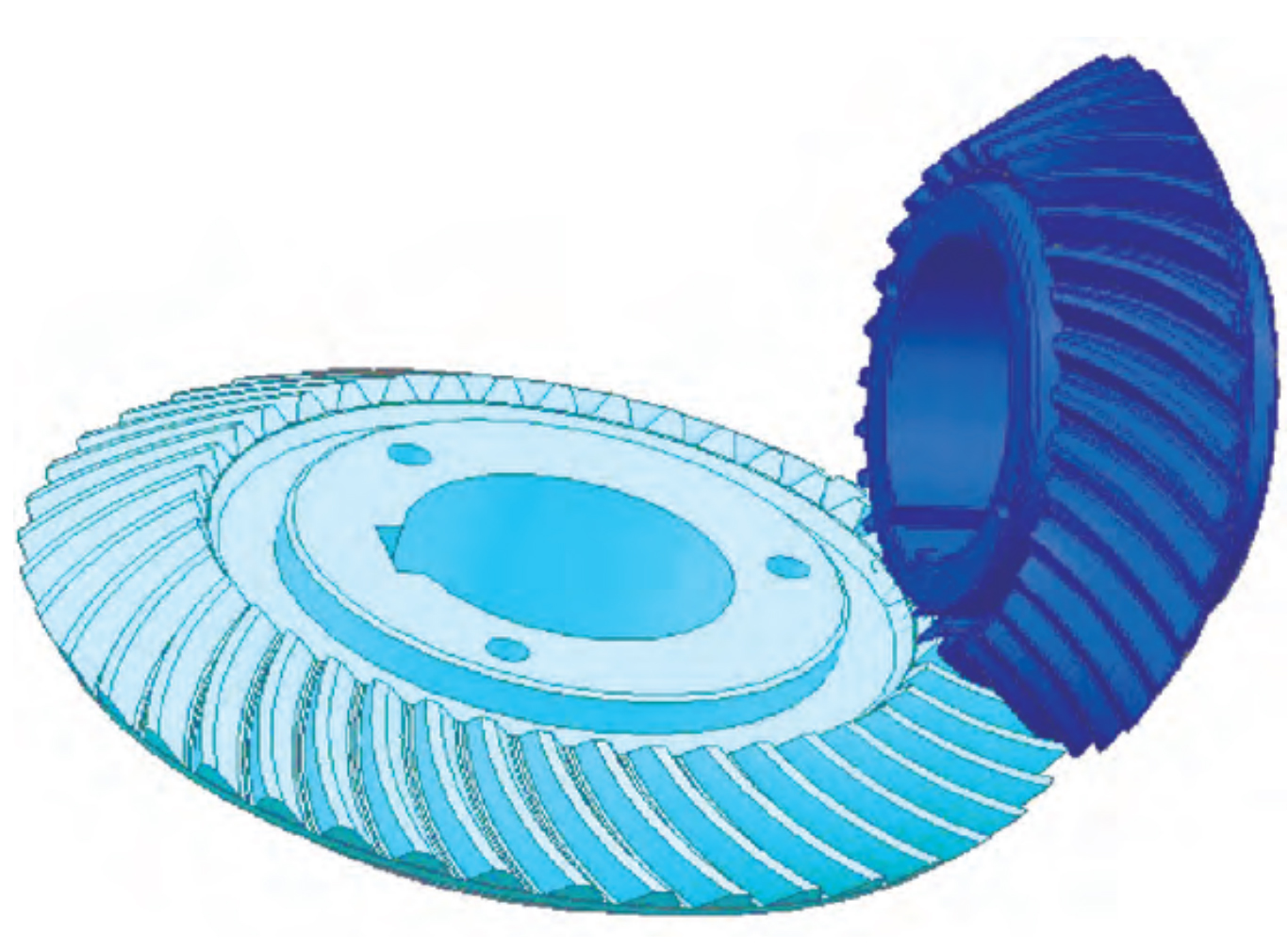

Noise and vibration are inherent challenges in gear-driven mechanical systems. However, the design and operation of spiral bevel gears allow for some unique strategies to mitigate these issues. This article will discuss several noise reduction strategies in the design of spiral bevel gears, highlighting their effectiveness in improving overall system performance and reliability.

1.Optimized Tooth Geometry:

The design and geometry of the gear teeth play a crucial role in noise production. The curvature and helical design of spiral bevel gears allow for more gradual tooth engagement compared to straight bevel gears, reducing impact and thus lowering noise. Furthermore, advances in computational capabilities allow for more precise and complex tooth designs, improving contact patterns and load distribution, which can further reduce noise.

2.Improved Material Selection:

Material choice can significantly influence the noise and vibration characteristics of spiral bevel gears. Materials with higher damping capabilities can absorb more vibration, leading to quieter operation. Additionally, the use of advanced, high-strength materials can minimize deformations under load, improving contact conditions and reducing noise.

3.Advanced Manufacturing Techniques:

Precision in manufacturing directly impacts the noise levels in gear operation. Techniques such as 5-axis CNC machining and gear grinding can produce gears with high dimensional accuracy and excellent surface finish, leading to smoother operation and reduced noise. These advanced manufacturing techniques can maintain tighter tolerances, which results in better meshing and lower noise generation.

4.Lubrication:

Proper lubrication is vital in reducing noise and vibration. It minimizes friction between the engaging gear teeth and can dampen some of the vibrations. The use of high-quality lubricants, and ensuring they are adequately applied, can have a significant impact on the noise levels of spiral bevel gears.

5.Precise Mounting and Alignment:

Misalignment of the gears can cause uneven load distribution and improper tooth engagement, leading to increased noise and potential damage. Precise mounting and alignment during installation can ensure optimal contact between the gear teeth and reduce noise.

6.Use of Damping and Insulation Materials:

The inclusion of damping and insulation materials in the gear housing can further reduce the noise heard by the operator. These materials absorb some of the noise and vibration energy, preventing it from being transmitted to the surroundings.

7.Finite Element Analysis (FEA):

Modern computational tools like FEA can simulate the behavior of spiral bevel gears under various operating conditions. These tools can help in predicting areas of stress concentration, identifying potential sources of noise, and optimizing the gear design to mitigate these issues.

Noise reduction in spiral bevel gears is a multi-faceted problem that requires attention at all stages, from design to manufacturing and operation. Advances in material science, manufacturing techniques, and computational tools, coupled with a better understanding of gear dynamics, have led to significant improvements in this area. With the continued emphasis on quieter and more efficient machinery, the strategies for noise reduction in spiral bevel gear design will continue to evolve and improve.