The power of the whole vehicle is transmitted to the rear axle by the engine through the clutch, gearbox and transmission shaft. The vibration of the spiral bevel gear of the rear axle is amplified during the loaded meshing process. The vibration of spiral bevel gear is transmitted to the vehicle body through various connecting parts to the inside of the vehicle, resulting in howling noise that can be perceived by human ears.

The vibration amplitude of the excitation source can be reduced by optimizing the structure of the rear axle, and the transmission of the excitation source to the vehicle body can be attenuated by optimizing the structure of the transmission shaft and suspension components, so as to reduce the noise of the rear axle.

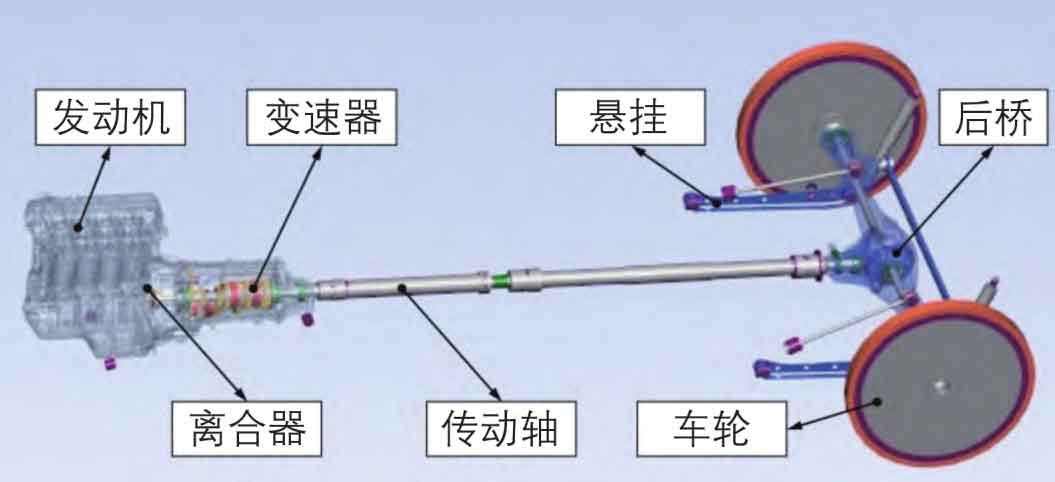

Vehicle power transmission system is a nonlinear elastic system with multi parameter excitation. A complete power transmission system analysis model composed of engine assembly, clutch, transmission, transmission shaft, rear axle, suspension system and wheels is established in Masta, as shown in Figure 1.

According to calculation, the corresponding engine speed is 2850-3200rpm when the vehicle is running at 90-100km / h. Relevant input parameters of Masta analysis model are shown in the table.

| Input speed | 800→4000rpm |

| Loading torque | 140N·m |

| Wheel load speed | 200→1150rpm |

| Wheel unilateral load torque | 245N·m |

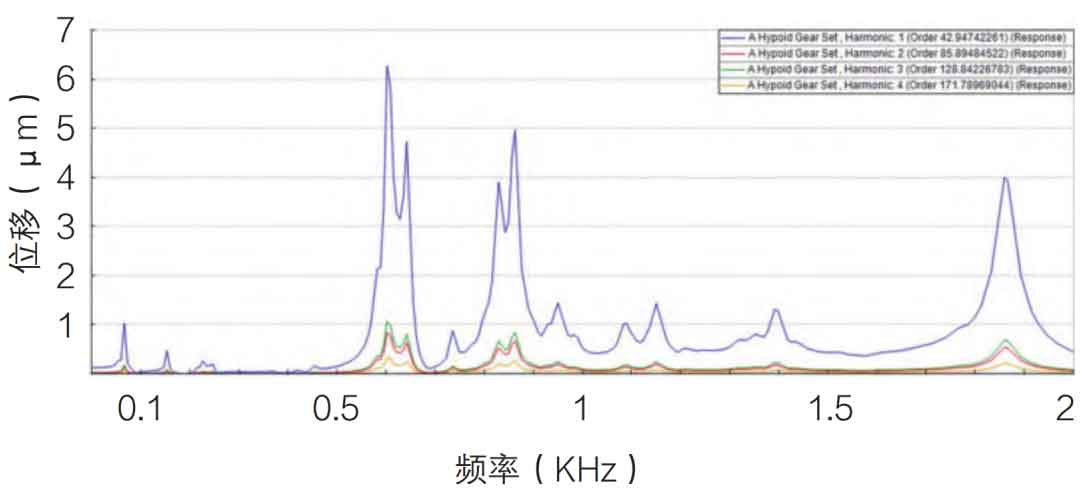

Load the model according to the input parameters. During acceleration, the vibration displacement response peak of the main gear bearing appears at 540hz ~ 640hz, as shown in Fig. 2. Through calculation, the frequency is consistent with the noise frequency of spiral bevel gear when the whole vehicle is running at 90-100km / h.

The vibration displacement response frequency of the main gear bearing is consistent when different spiral bevel gear parameters are set in the Masta model. The amplitude of the vibration acceleration of the main gear bearing is slightly different, so the amplitude of the vibration acceleration of the main gear bearing can be used to characterize the noise of the spiral bevel gear.

Through the combination analysis of different optimization schemes, it is concluded that the main factors affecting the vibration acceleration amplitude of the main gear bearing are the insufficient support stiffness of the main reducer housing, differential housing and bearing, the excessive transmission error design of the spiral bevel gear, and the resonance phenomenon on the transmission path.