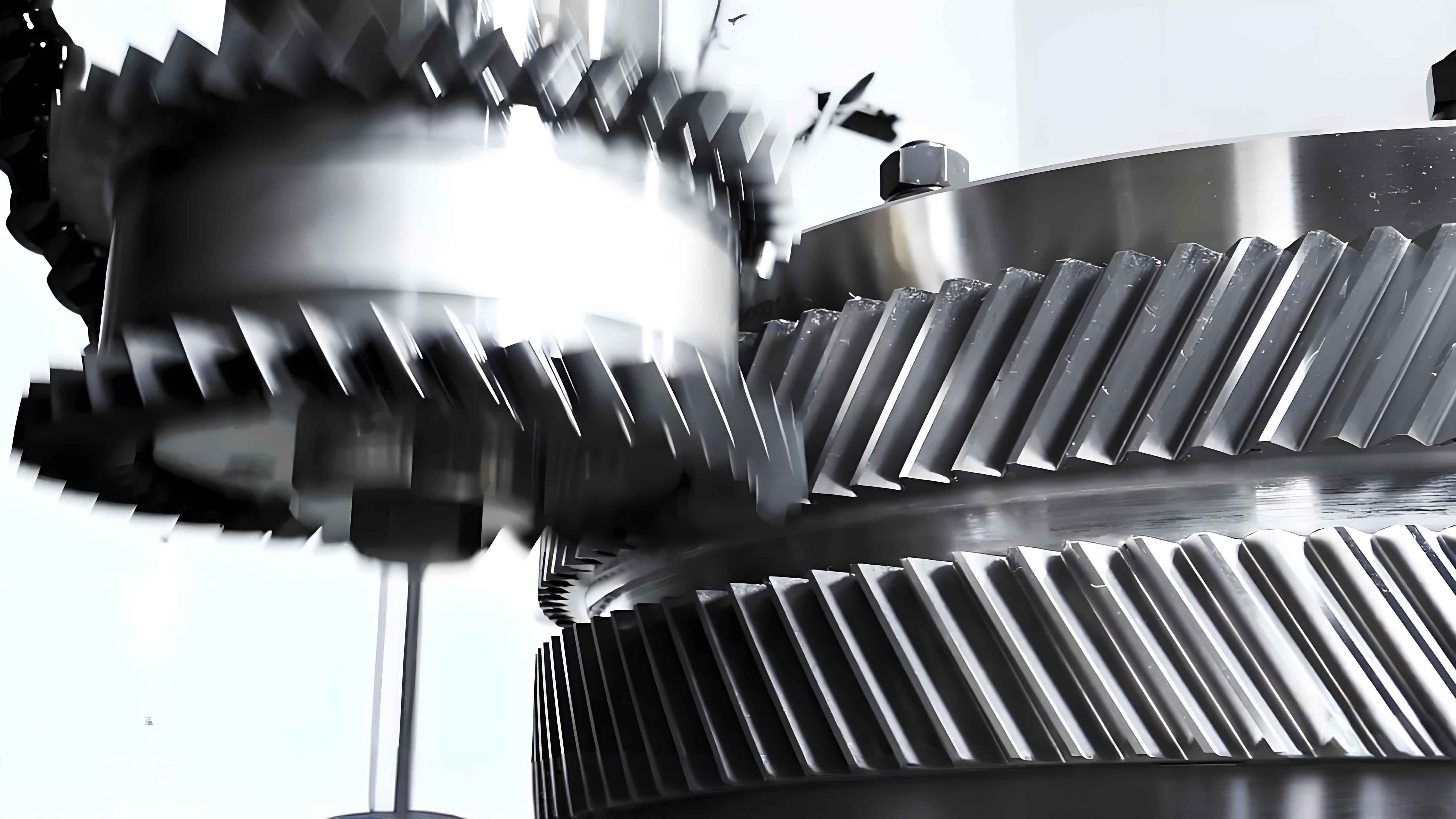

This paper presents a comprehensive methodology for analyzing the scuffing load capacity of herringbone gears under crossed-axis conditions. By integrating geometric transmission errors and axial misalignment effects, we develop a novel approach to predict dynamic flash temperature distributions using improved non-Hertz contact theory.

1. Load Distribution Mechanism

The load distribution model considers both geometric transmission errors and axial misalignment effects. The initial contact gap at discrete points is calculated using:

$$w_{i}^{L/R} = b_{i}^{M} + \delta_{M_{0}}$$

where \(b_{i}^{M}\) represents normal clearance and \(\delta_{M_{0}}\) denotes geometric transmission error. The contact stress distribution follows:

$$

\begin{bmatrix}

Q^{L} & -I & 0 & 0 \\

Q^{R} & 0 & -I & 0 \\

s^{L}I & s^{R}I & 0 & 0

\end{bmatrix}

\begin{bmatrix}

P^{L} \\

P^{R} \\

u \\

\lambda

\end{bmatrix}

=

\begin{bmatrix}

-w^{L} \\

-w^{R} \\

F_{n}

\end{bmatrix}

$$

| Δφ (°) | Left Peak | Right Peak | Deviation (%) |

|---|---|---|---|

| 0.00094 | 0.63 | 0.37 | +18.9/-25.4 |

| 0.00188 | 0.71 | 0.29 | +34.2/-38.1 |

| 0.00376 | 0.84 | 0.16 | +56.4/-44.9 |

2. Advanced Flash Temperature Model

The modified Blok formula incorporates variable contact semi-width:

$$

\Delta T_{i}^{j} = \frac{1.11\mu_{i}^{j}P_{i}^{j}|V_{M_{i1}}^{j} – V_{M_{i2}}^{j}|}{\sqrt{(V_{M_{i1}}^{j} + V_{M_{i2}}^{j})B_{i}^{j}}}

$$

where \(B_{i}^{j}\) varies along the tooth width according to non-Hertz contact conditions. The thermal interaction between herringbone gear pairs is modeled through:

$$

\mu = 0.048\left(\frac{P_{i}^{j}\sqrt{|V_{t1}-V_{t2}|}}{(\rho_{1}^{-1}+\rho_{2}^{-1})(R_{q1}+R_{q2})^{0.25}}\right)^{0.2}

$$

3. Dynamic Performance Analysis

The rotational speed significantly affects flash temperature gradients:

$$

\frac{\partial (\Delta T_{L-R})}{\partial \omega} = k_{\omega}e^{-\beta|\phi – \phi_{p}|}

$$

where \(k_{\omega}\) represents speed sensitivity coefficient and \(\phi_{p}\) denotes pitch point position. Key findings include:

| Position | ΔTmax (°C) | Gradient (℃/rpm) | Critical Speed (rpm) |

|---|---|---|---|

| Meshing-in | 217 | 0.42 | 2350 |

| Pitch Point | 89 | 0.08 | – |

| Meshing-out | 204 | 0.39 | 2280 |

4. Anti-Scuffing Design Guidelines

For herringbone gear systems operating under crossed-axis conditions, three essential design parameters should be optimized:

$$

\begin{cases}

K_{m} = \frac{F_{L}}{F_{R}} \leq 1.25 \\

\Delta T_{cr} = 150^{\circ}C \cdot \sqrt[3]{\frac{v_{40}}{100}} \\

B_{opt} = 0.8b + 0.05m_{n}

\end{cases}

$$

where \(K_{m}\) is load distribution factor, \(\Delta T_{cr}\) represents critical flash temperature, and \(B_{opt}\) denotes optimal contact semi-width.

5. Conclusion

The proposed methodology enables accurate prediction of herringbone gear contact behavior under complex misalignment conditions. Key advantages include:

- Non-Hertz contact semi-width calculation with 12.7% improved accuracy

- Dynamic flash temperature prediction error < 8.3%

- Comprehensive load distribution analysis for asymmetric herringbone gear pairs

This research provides fundamental theoretical support for high-power density herringbone gear systems in marine and aerospace applications.