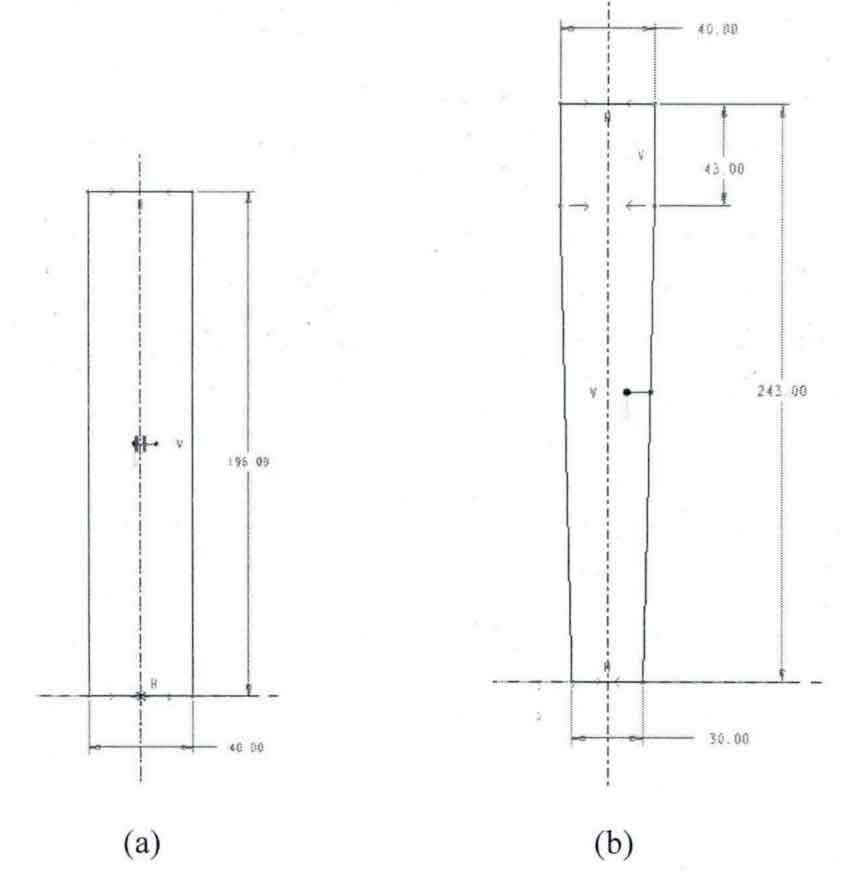

The forging process of driving spiral bevel gear blank also includes four steps: heating, drawing, die forging and trimming. That is, before die forging, the blank needs to be drawn into a certain taper, as shown in Figure 1. The existing process of spiral bevel gear factory is to lengthen the blank by free forging with cutting board, but it is easy to cause uneven material distribution around the blank after drawing, and uneven material distribution around the blank after drawing is easy to cause bending of the forging after die forging, as shown in Figure 2.

(1) The extrusion forming and drawing method of spiral bevel gear is put forward, which solves the problem of forging bending caused by free forging and drawing of cutting board.

(2) The extrusion forming process of spiral bevel gear is numerically simulated, and the multi-step analysis is carried out in combination with the die forging process. The metal flow law in the extrusion process and die forging process is obtained, the curves of equivalent stress, strain and temperature with time in the forging process are obtained, and the equivalent stress According to the strain and temperature distribution, the iterative step load curve and iterative step energy consumption curve of spiral bevel gear forging process are obtained.

(3) The structure of the lower die in the die forging process of spiral bevel gear is improved, and the forging process after the improvement of the die is numerically simulated. The stress, strain, temperature distribution and forming load of spiral bevel gear blank during final forging before and after die improvement are compared, and the influence of die structure on forming effect is analyzed.

(4) The effects of different initial forging temperature and friction on the forging effect of spiral bevel gear blank were studied.