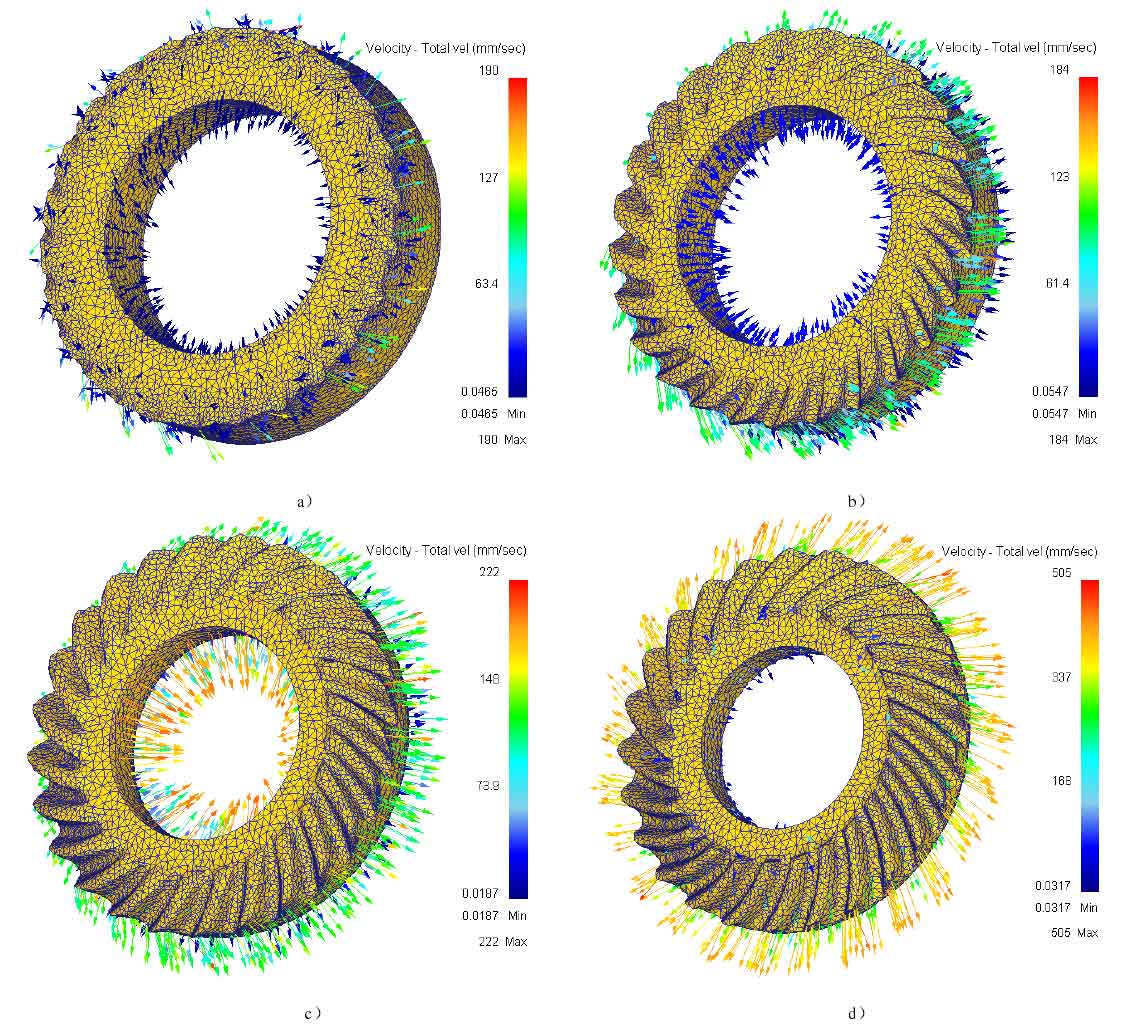

Through the speed field of precision forging of spiral bevel gear, the flow of metal blank in the forming process can be grasped intuitively. As shown in the figure, the velocity field distribution of the upper die under different reduction is shown.

At the beginning of deformation (as shown in Fig. A and b), the outer profile part of the upper end face of the blank is in contact with the tooth top of the tooth die. Under the action of the tooth die, the metal flow of the blank is mainly concentrated in the tooth root of the spiral bevel gear forging; With the downward movement of the gear die and the floating die, the inner contour part of the upper end face of the blank contacts the gear die and is subjected to the axial force of the gear die. While filling the tooth cavity, the blank metal undergoes axial upsetting deformation (as shown in Figure C). Due to the ring shape of the blank, there is a diversion surface when upsetting deformation occurs, and the metals on both sides of the diversion surface flow in the opposite radial direction, This can effectively reduce the forming force; In the final stage of forming (as shown in Figure d), the metal flow is mainly concentrated in the tooth root part of the big end of the tooth shape, so that the metal fills the die bore. In the whole process of forming, the metal not only has radial flow and axial flow, but also has tangential flow when filling the tooth cavity because the tooth shape of spiral bevel gear is spiral tooth.