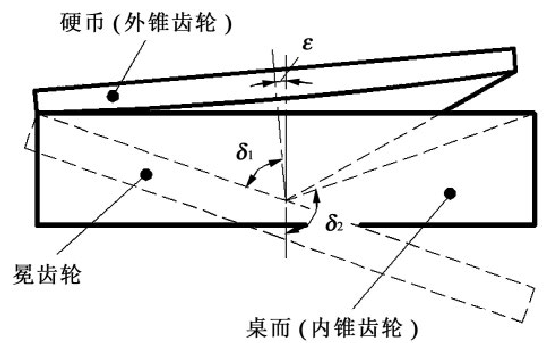

The wobble of a coin on the table before it stops is nutation. A nutation transmission mechanism is formed by replacing the coin and the table with a pair of outer and inner bevel gears respectively. The outer bevel gear rotates around its own axis, and there is a small constant nutation angle between the axis and the input shaft, while the inner bevel gear is axially fixed, as shown in Fig. 1. In Fig. 1, only pitch cone surface is used to represent the two bevel gears. The crown gear is an imaginary intermediate gear meshing with the inner and outer bevel gears respectively. The pitch angles of outer bevel gear, inner bevel gear and crown gear are δ 1, δ 2 and π 2 respectively, and δ 1 + δ 2 + ε = π.

According to this principle, the nutation transmission mechanism of single-stage bevel gear is designed, which is mainly composed of nutation outer bevel gear 1, fixed internal bevel gear 2, universal coupling 3, input shaft 4 and output shaft 5, as shown in Fig. 2. There is a nutation angle ε between the inclined axis and the input shaft, and it is fixedly connected with the input shaft. Nutation outer bevel gear 1 is installed on the inclined shaft and can rotate freely. Driven by the helical shaft, it is meshed with the fixed internal bevel gear 2. The speed of nutation outer bevel gear around the inclined shaft will be transmitted to the output shaft through universal coupling, so as to achieve the purpose of deceleration.

The nutation transmission mechanism of bevel gear is a variation of planetary gear transmission with small tooth difference. It combines spiral bevel gear transmission with nutation transmission organically, and has the characteristics of small radial size, large transmission ratio and large transmission power. Compared with the conventional cylindrical gear transmission, the radial size of the mechanism is mainly determined by the diameter of a single bevel gear, so it can obtain a larger transmission ratio in a smaller space. The mechanism is suitable for the situation that the radial size of reducer is strictly required, such as the electric submersible screw pump oil production system in oil exploitation.

The transmission ratio of single-stage nutation transmission mechanism is as follows: the number of teeth of outer and inner bevel gears are Z1 and Z2 respectively

It can be seen from the formula that the transmission ratio will increase gradually with the decrease of nutation angle ε. When the nutation angle is small enough, a large transmission ratio can be obtained.