The optimization goal is to reduce the forming load and increase the filling rate of gear forging.

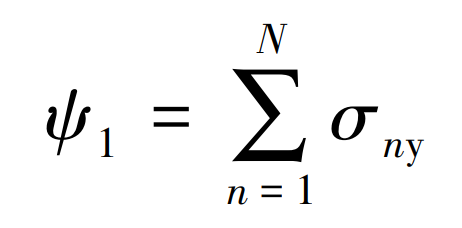

(1) Objective function model of forming load. The maximum load of gear forging process is the final forging force. Optimizing the forming load can not only save production energy consumption, but also reduce the fatigue wear of equipment. The final forging force can be calculated by the sum of the vertical forces of each contact unit between the gear forging and the upper die, that is:

Where: ψ 1 is the vertical load; N is the unit number of gear forging in contact with the upper die, n = 1, 2,…, N; N is the total number of units; σ NY is the load of element n in the vertical direction.

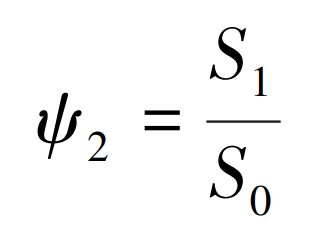

(2) Filling rate objective function model. Record the surface area of the final gear forging when it is fully filled as S0. In the actual forming simulation process, the contact surface area between the gear forging and the die is recorded as S1, which can be calculated by the finite element simulation software DEFORM. Then the filling rate is:

Where: ψ 2 is the filling rate.

| Parameters | Potential / V | Press speed / (mm · s-1) | Friction factor | Blank temperature / ℃ |

| Numerical value | 050~ 0. 450 | 40~ 100 | 10~ 0. 30 | 800~ 1200 |

In order to achieve the optimization goal and improve the quality of gear forgings, the preformed shape (i.e. potential ξ)、 Press speed V, friction factor μ、 The gear blank temperature T is the optimization parameter. According to the actual situation and experience of the experimental equipment, the optimization range of each parameter is set as shown in Table.