The open die forging of bevel gear with friction press can not ensure that each tooth shape cavity can be fully filled at one time, that is, the yield is low, and the flash must be removed and then forged again. Therefore, the open die forging of bevel gear needs two steps of pre forging and final forging. At present, the precision die forging process of straight bevel gear with friction press mainly includes warm forging, warm forging finishing, hot forging and cold forging finishing.

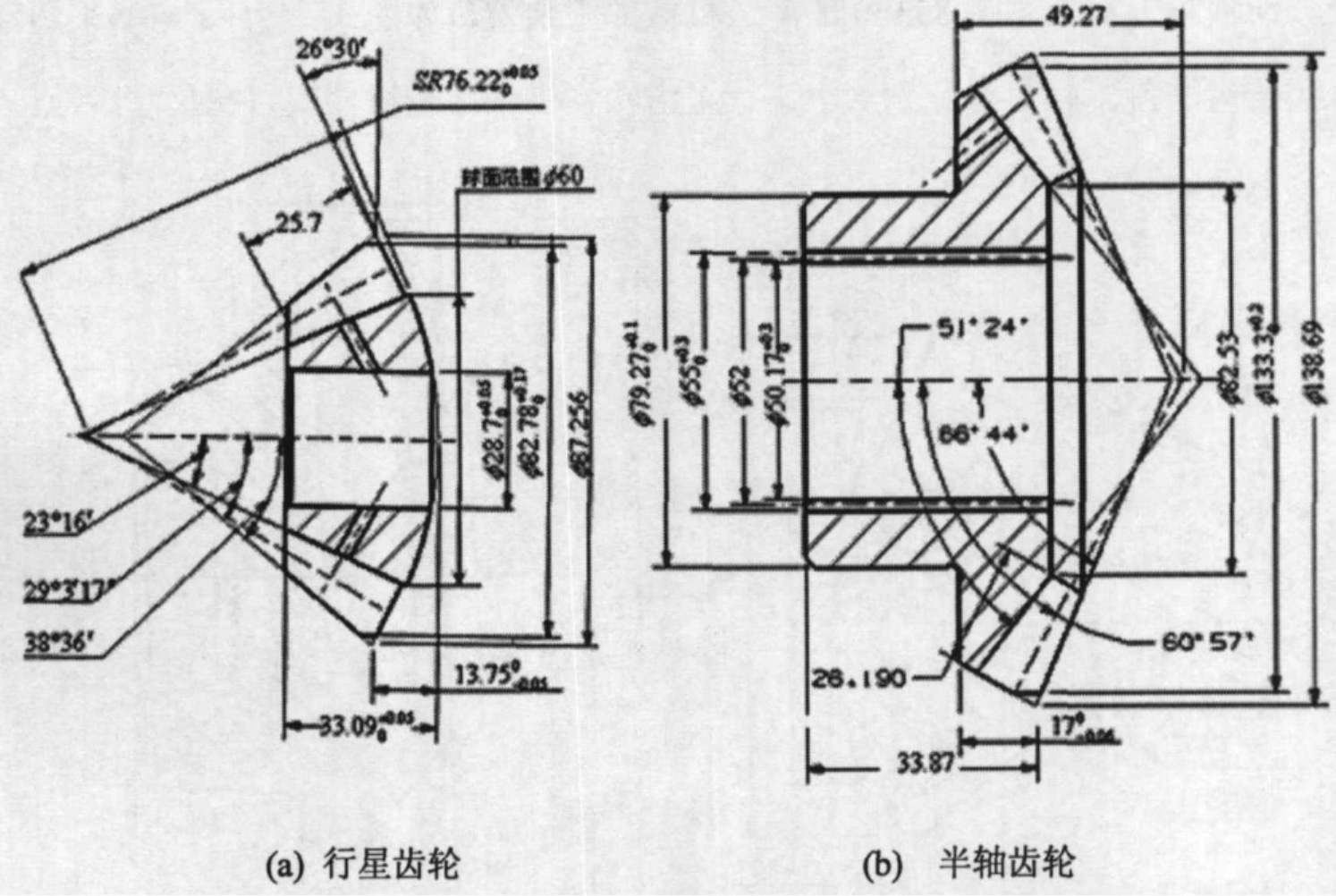

The basic parameters of the planetary gear and half shaft gear shown in the figure are listed in the table. The bevel gear is made of 20CrMnTi, which has large deformation resistance. The gear module is 7.41, and the forging size is large, resulting in large deformation force of precision forged planetary gear and half shaft gear. Therefore, the “one fire two forging” process of hot forging, warm forging and finishing is adopted to form planetary gears and half shaft gears.

| Parameter name | Planet gear | Halfshaft gear |

| Modulus | 7.41 | 7.41 |

| Number of teeth | 10 | 18 |

| Pressure angle | 25° | 25° |

| Fractional cone angle | 29.0547° | 60.9453° |

| Equivalent number of teeth | 11.44 | 37.06 |

| Addendum height coefficient | 0.900 | 0.900 |

| Coefficient of top clearance | 0.208 | 0.208 |

| Radial displacement coefficient | 0.163 | -0.163 |

| Tangential displacement coefficient | 0 | 0 |

The forging temperature of 20CrMnTi ranges from 800 ℃ to 1200 ℃, and the initial forging temperature of pre forging is set at 1100 ℃. At this temperature, the deformation resistance of the material is low, and the basic forming of bevel gear can be completed under low deformation force. The initial forging temperature of the final forging is set at 800 ℃. At this temperature, the deformation resistance of the material has been large. However, due to the small deformation during the final forging process, it can also be ensured that the deformation force is not large. In addition, the oxidation of the material is no longer obvious at this temperature, which can ensure that the bevel gear has better surface quality. The process flow is as follows: cutting off oxide skin in a cart of blanks, heating to 1150 ℃, pre forging to 1100 ℃, hot trimming, steel wire brushing to remove oxide skin, final forging to 800 ℃, sand cooling to room temperature, cold cutting and trimming, sand blasting.