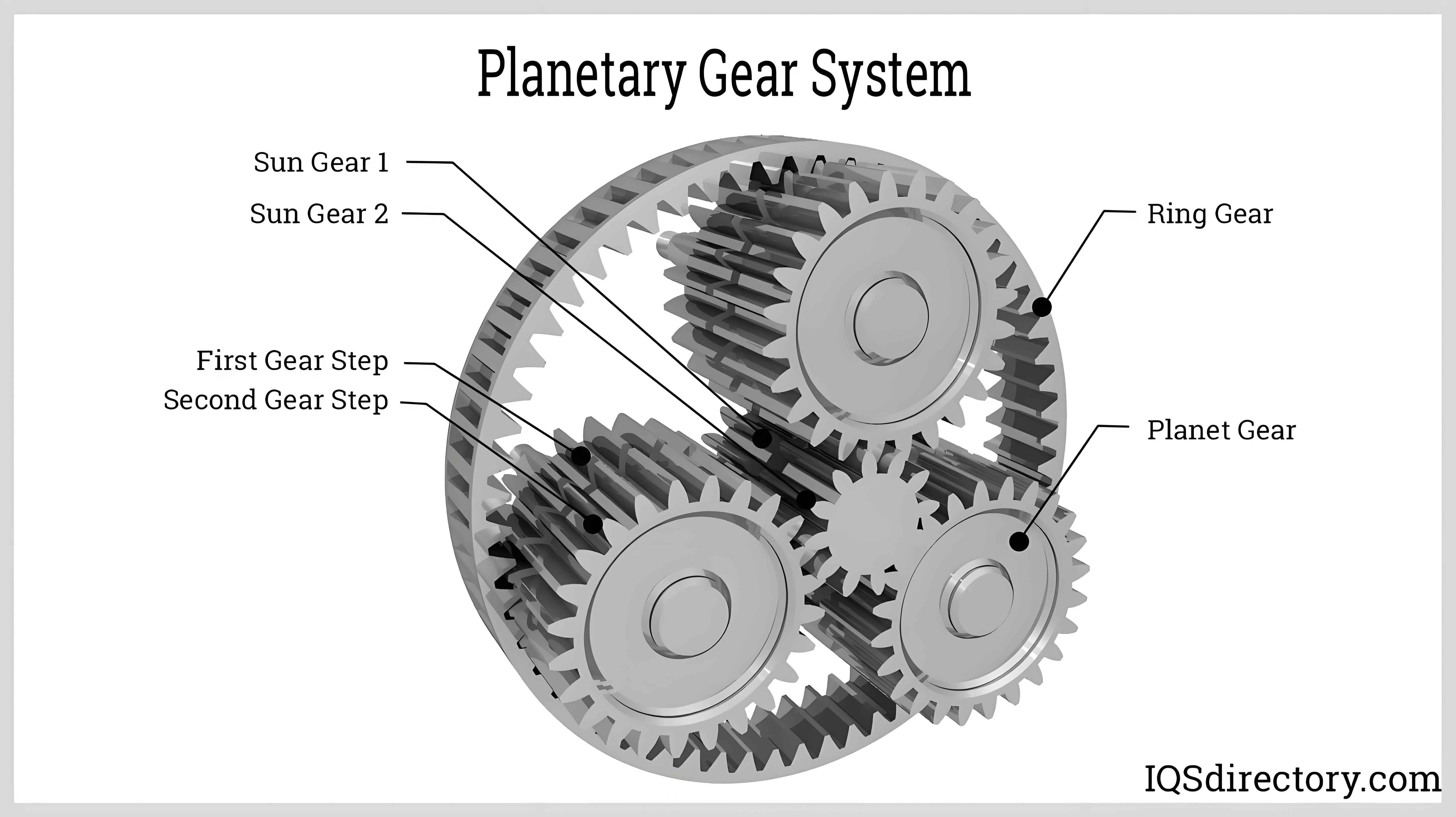

This paper presents an optimization methodology for reducing the volume of planetary gear systems in thin-seam shearer rocker arms while maintaining operational reliability. Focusing on NGW-type planetary transmission mechanisms, we establish a comprehensive mathematical model considering multiple constraints including gear strength requirements and planetary configuration conditions.

1. Mathematical Modeling

1.1 Design Variables

Five key parameters were selected as optimization variables:

$$ \mathbf{x} = [Z_a, Z_b, Z_c, b, m_n]^T $$

Where:

$Z_a$ = Sun gear teeth count

$Z_b$ = Ring gear teeth count

$Z_c$ = Planet gear teeth count

$b$ = Tooth width (mm)

$m_n$ = Module (mm)

1.2 Objective Function

Minimize total planetary gear system volume:

$$ f(\mathbf{x}) = \frac{\pi}{4}x_4^2\left[x_1^2 + x_3^2 + 4x_5^2\right]x_2 $$

Where $x_1$-$x_5$ correspond to the design variables in sequence.

1.3 Constraints

Key constraints for planetary gear optimization:

| Constraint Type | Mathematical Expression |

|---|---|

| Contact Stress | $$ \frac{766}{\sigma_{Hlim}}\sqrt[3]{\frac{T_aK_Ak_\beta(i+1)}{bd^2i}} \geq 1 $$ |

| Bending Stress | $$ \frac{12.6T_aK_Ak_\beta Y_F}{bm_n^2Z_a\sigma_{Flim}} \geq 1 $$ |

| Assembly Condition | $$ Z_a + Z_b = N \cdot C_s $$ |

| Adjacency Condition | $$ (Z_a + Z_c)\sin(\pi/C_s) > Z_c + 2 $$ |

2. Optimization Methodology

2.1 Nonlinear Programming Approach

The fmincon solver with sequential quadratic programming (SQP) was implemented with initial parameters:

$$ \mathbf{x}_0 = [17, 83, 33, 175, 9]^T $$

2.2 Genetic Algorithm Implementation

Key GA parameters for planetary gear optimization:

| Parameter | Value |

|---|---|

| Population Size | 500 |

| Crossover Probability | 0.8 |

| Mutation Probability | 0.1 |

| Generations | 500 |

3. Optimization Results

Comparative results of planetary gear optimization:

| Parameter | Initial | fmincon | GA |

|---|---|---|---|

| Sun Gear Teeth ($Z_a$) | 17 | 19 | 17 |

| Planet Gear Teeth ($Z_c$) | 33 | 31 | 31 |

| Ring Gear Teeth ($Z_b$) | 83 | 81 | 79 |

| Tooth Width (mm) | 175 | 171 | 172 |

| Module (mm) | 9 | 8 | 8 |

| System Volume (mm³) | 1.184×10⁸ | 9.254×10⁷ | 8.969×10⁷ |

| Volume Reduction | – | 21.8% | 24.3% |

4. Planetary Gear Performance Analysis

The optimized planet gear system demonstrates significant improvements:

$$ \Delta V_{GA} = \frac{V_{initial} – V_{GA}}{V_{initial}} \times 100\% = 24.3\% $$

Key contact stress reduction for planet gears:

$$ \sigma_H^{optimized} = 0.87\sigma_H^{initial} $$

5. Conclusion

This study demonstrates effective volume reduction strategies for planetary gear systems in thin-seam shearers. The genetic algorithm showed superior performance in finding global optima for planet gear configurations, achieving 24.3% volume reduction while maintaining required strength characteristics. The optimization framework provides valuable insights for high-power-density planetary gear design in constrained mining environments.