As a key component in electric drive axle reducers, transmission gears directly impact performance metrics such as efficiency, noise, and service life. This study focuses on optimizing transmission gear parameters through macro- and micro-level adjustments, leveraging Romax software for simulation-driven design. Below, I present a detailed analysis of the methodology, results, and implications of this optimization process.

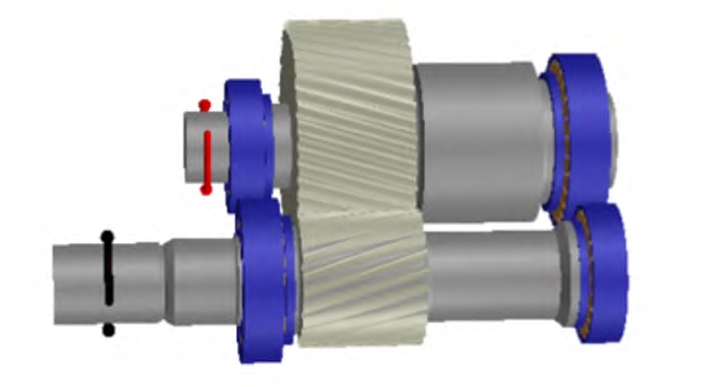

1. Gear Modeling and Initial Performance Analysis

The study begins with establishing a baseline gear model using Romax software. Key parameters of the original transmission gear pair are summarized in Table 1.

Table 1: Initial Gear Parameters

| Parameter | Driving Gear | Driven Gear |

|---|---|---|

| Helix Direction | Left | Right |

| Number of Teeth | 22 | 47 |

| Profile Shift | 0.48 | -0.556 |

| Normal Module (mm) | 1.75 | |

| Normal Pressure Angle (°) | 20 | |

| Helix Angle (°) | 17 | |

| Center Distance (mm) | 63 | |

| Material | MQ-grade surface-hardened steel | |

| Precision Grade | ISO Class 6 |

Material properties of the selected steel are critical for fatigue analysis (Table 2).

Table 2: Gear Material Properties

| Property | Value |

|---|---|

| Elastic Modulus (MPa) | 207,000 |

| Yield Strength (MPa) | 314 |

| Ultimate Strength (MPa) | 2,180 |

| Surface Hardness (HV) | 670 |

| Core Hardness (HRC) | 31 |

| Allowable Contact Stress (MPa) | 1,500 |

| Allowable Bending Stress (MPa) | 500 |

Using the S-N curve assumption method, the equivalent load spectrum was derived from real-world operating conditions (Table 3).

Table 3: Operational Load Spectrum

| Parameter | Value |

|---|---|

| Torque (N·m) | 360 |

| Power (kW) | 140 |

| Duration (h) | 34.5 |

Initial simulations revealed critical weaknesses in bending and contact fatigue safety factors (Table 4).

Table 4: Initial Gear Strength Analysis

| Parameter | Driving Gear | Driven Gear |

|---|---|---|

| Bending Fatigue Safety Factor | 1.92 | 1.58 |

| Contact Fatigue Safety Factor | 1.07 | 1.13 |

| Flash Temperature Safety Factor | 1.22 | — |

| Mean Temperature Safety Factor | 1.37 | — |

| Transmission Error (μm) | 0.93162 | — |

2. Macro-Parameter Optimization

To address suboptimal safety factors, a full factorial Design of Experiments (DoE) was conducted using Romax. Variables included pressure angle, module, and helix angle. Key findings are summarized below:

2.1 Impact of Pressure Angle Reduction

Reducing the pressure angle from 20° to 18° improved contact stress distribution by increasing the contact ratio. The revised parameters (Table 5) resulted in:

Table 5: Optimized Macro-Parameters

| Parameter | Driving Gear | Driven Gear |

|---|---|---|

| Number of Teeth | 24 | 51 |

| Pressure Angle (°) | 18 | |

| Helix Angle (°) | 19 | |

| Contact Ratio | 4.89 |

Key Outcomes:

- Bending fatigue safety factor increased by 33% (from 1.92 to 2.56).

- Transmission error reduced by 42.3% (from 0.93162 μm to 0.53729 μm).

2.2 Mathematical Formulation for Contact Ratio

The contact ratio (ε) is calculated as:ε=Z1+Z22π(tanαt−tanαw)ε=2πZ1+Z2(tanαt−tanαw)

where:

- Z1,Z2Z1,Z2 = Number of teeth on driving/driven gears

- αtαt = Transverse pressure angle

- αwαw = Working pressure angle

3. Micro-Parameter Optimization: Gear Micro-Geometry Modification

Micro-geometry modifications, including profile and lead crowning, were applied to further reduce transmission error and improve load distribution.

3.1 Crowning Calculations

- Lead Crowning (CcCc):

Cc=2FmFpCy,bCc=Cy,b2FmFp

where:

- FmFm = Circumferential force (N)

- FpFp = Misalignment (μm)

- CyCy = Combined tooth stiffness (GPa)

- bb = Face width (mm)

- Profile Crowning (ΔmaxΔmax):

Δmax=KdFtεαCybΔmax=εαCybKdFt

where:

- KdKd = Application factor (1.25)

- FtFt = Tangential force (N)

Table 6: Optimized Micro-Parameters

| Parameter | Value (μm) |

|---|---|

| Lead Crowning | 8 |

| Profile Crowning | 6 |

| Lead Tilt | -7 |

| Profile Tilt | 0 |

3.2 Post-Modification Performance

Post-optimization simulations demonstrated significant improvements (Table 7):

Table 7: Final Gear Performance Metrics

| Parameter | Driving Gear | Driven Gear |

|---|---|---|

| Bending Fatigue Safety Factor | 1.66 | 1.49 |

| Contact Fatigue Safety Factor | 1.11 | 1.18 |

| Transmission Error (μm) | 0.21883 | — |

Key Outcomes:

- Transmission error reduced by 76% (from 0.93162 μm to 0.21883 μm).

- Contact stress distribution shifted to the center of the tooth face, minimizing edge loading.

4. Noise and Vibration Validation

A comparative noise test validated the optimized transmission gear design. Post-optimization noise levels showed:

- Reduction in peak noise amplitude by 8–12 dB.

- Shifted noise frequency harmonics, reducing perceptible vibration.

5. Conclusion

Through macro- and micro-parameter optimization, the transmission gear design achieved:

- 33% increase in bending fatigue safety factor.

- 76% reduction in transmission error.

- 41.8% improvement in flash temperature safety factor.

- Enhanced noise performance via load distribution uniformity.

The integration of Romax software enabled systematic parameter tuning, reducing reliance on empirical methods. This approach not only enhances transmission gear performance but also streamlines design cycles, offering a robust framework for future electric drive axle development.