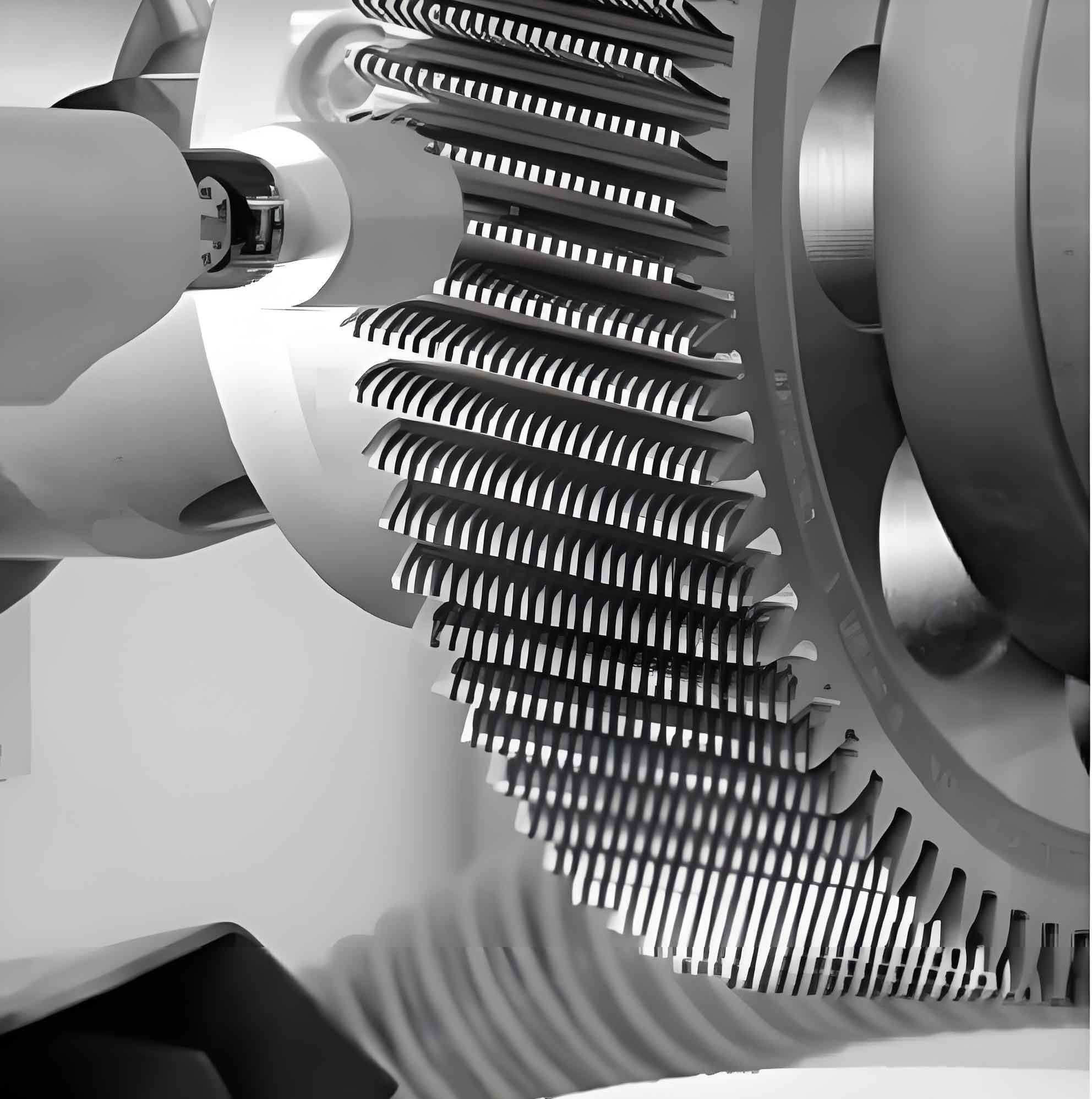

Gear shaving stands as a critical precision finishing process in gear manufacturing, where optimal cutting parameters directly influence energy consumption, tool life, and surface quality. Traditional parameter selection often prioritizes productivity over sustainability, leading to excessive energy usage. This paper presents a genetic algorithm (GA)-based optimization framework for minimizing energy consumption in gear shaving operations while maintaining machining quality.

The optimization model defines energy consumption \( W \) as the primary objective function, expressed as:

$$W = f(v, m, \gamma, s_p, x_e)$$

where \( v \) denotes spindle speed, \( m \) represents feed per gear tooth, \( \gamma \) is pinion rotational velocity, \( s_p \) is maximum cutting depth perpendicular to feed direction, and \( x_e \) is maximum cutting depth parallel to feed direction. Energy components include:

$$W = W_{\text{spindle}} + W_{\text{feed}} + W_{\text{auxiliary}} + W_{\text{cutting}}$$

Critical constraints ensure operational feasibility and quality in gear shaving processes:

- Cutting speed constraints:

$$n_{\text{min}} \leq n \leq n_{\text{max}} \quad \text{where} \quad v_r = \pi d n$$ - Feed rate constraints:

$$f_{\text{min}} \leq f \leq f_{\text{max}} \quad \text{and} \quad s_p \leq \text{ToolRadius}$$ - Surface roughness constraints:

$$Q = k \cdot \frac{f^2}{r_\epsilon} \leq [Q]$$

where \( r_\epsilon \) is tool nose radius and \( k \) is material coefficient

The multi-objective optimization problem is solved through a GA implementation with the following workflow:

| Step | Operation | Description |

|---|---|---|

| 1 | Initialization | Generate random population of parameter sets |

| 2 | Non-dominated sorting | Rank solutions using Pareto dominance |

| 3 | Crowding distance | Calculate density estimation for diversity preservation |

| 4 | Selection | Choose parents via binary tournament selection |

| 5 | Crossover & Mutation | Apply SBX and polynomial mutation operators |

| 6 | Replacement | Create new generation through elitism |

Experimental validation employed a YJL26615G gear shaving machine with DP20 high-speed steel tools. The comparative results demonstrate significant energy reduction:

| Machining time (hours) | Pre-optimization (kWh) | Post-optimization (kWh) | Reduction (%) |

|---|---|---|---|

| 4 | 2.364 | 0.694 | 70.6 |

| 8 | 4.246 | 1.264 | 70.2 |

| 12 | 8.242 | 2.384 | 71.1 |

| 16 | 15.648 | 4.682 | 70.1 |

| 20 | 18.692 | 9.456 | 49.4 |

| 24 | 23.365 | 10.381 | 55.6 |

The algorithm optimized key gear shaving parameters as follows:

$$v_{\text{opt}} = 163 \text{ rpm}, \quad s_p = 5.5 \text{ mm}, \quad f_{\text{opt}} = 2.4 \text{ mm/rev}$$

Energy reduction reached 55-71% across test durations while maintaining surface roughness below Ra 1.6 μm. The fitness convergence demonstrates GA effectiveness:

$$F_{\text{min}}(t) = W_0 \cdot e^{-\alpha t} \quad \alpha > 0$$

where \( F_{\text{min}} \) represents minimum energy found at generation \( t \).

This approach enables sustainable gear shaving operations through intelligent parameter selection. The GA framework effectively balances competing objectives in gear shaving processes—minimizing energy consumption while preserving machining quality. Future work will integrate real-time monitoring for adaptive optimization during gear shaving operations.