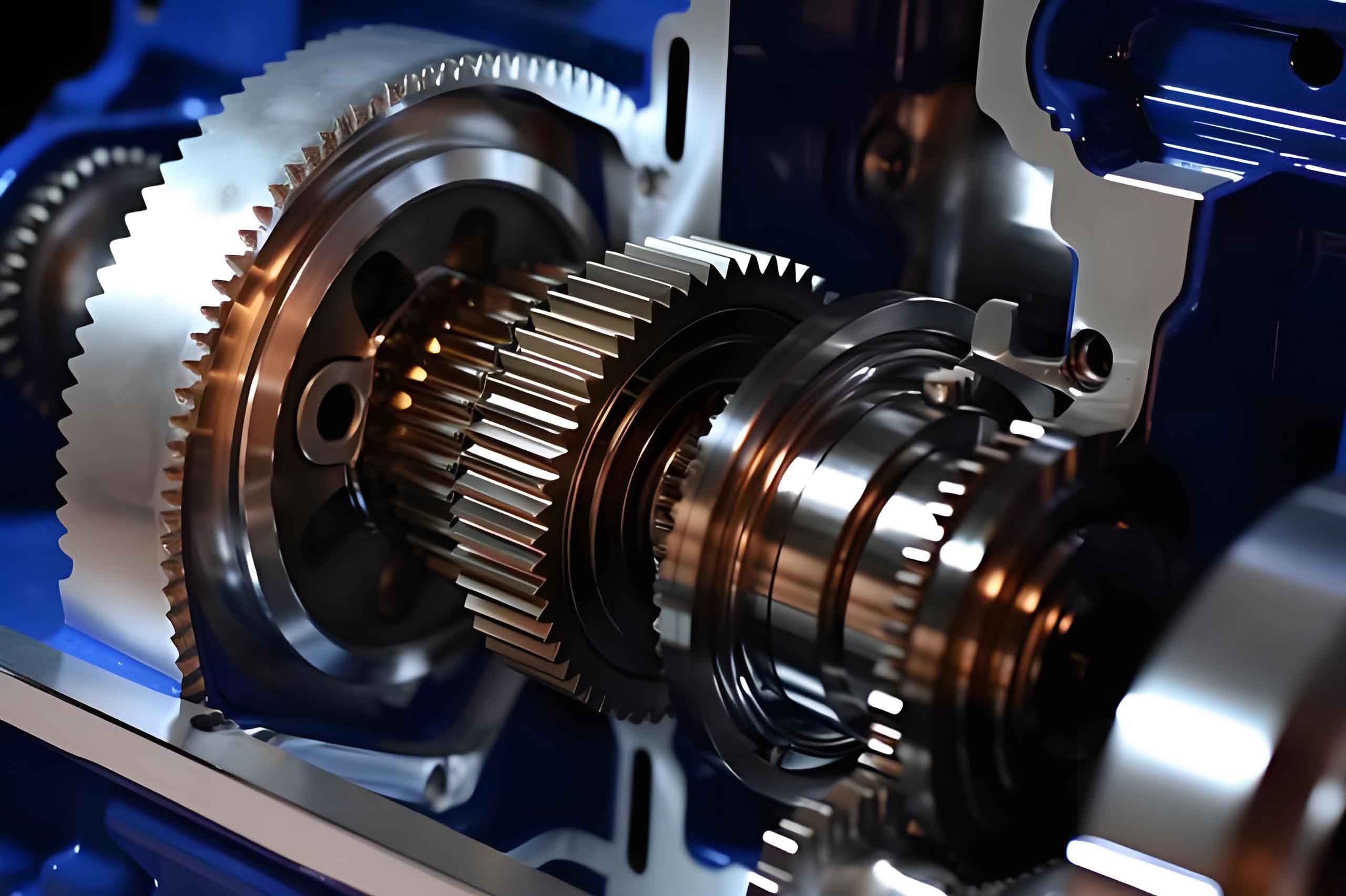

Automotive gears constitute critical components in vehicle transmission systems, where quality directly impacts operational safety and noise performance. This research investigates the optimization of heat treatment processes for automotive gear forging blanks using 20MnCr5 steel, aiming to enhance wear resistance and reduce deformation during carburizing and quenching. Through comparative analysis of isothermal annealing and conventional annealing techniques, significant improvements in mechanical properties were achieved.

1. Heat Treatment Processes for Automotive Gear Manufacturing

Automotive gear production from low-carbon alloy carburizing steel involves five critical stages: forging, pre-heat treatment, machining, carburizing quenching, and precision finishing. Pre-heat treatment fundamentally determines the automotive gear’s microstructure homogeneity and subsequent processing stability.

| Element | C | Si | Mn | S | P | Cr | Fe |

|---|---|---|---|---|---|---|---|

| wt.% | 0.198 | 0.182 | 1.325 | 0.024 | 0.031 | 1.250 | Bal. |

The wear resistance equation for automotive gear materials demonstrates the critical relationship between hardness (H) and wear coefficient (k):

$$W = k \frac{F_n}{H}$$

where \(W\) represents wear volume, and \(F_n\) denotes normal load. This highlights why optimizing heat treatment to maximize hardness is essential for automotive gear longevity.

2. Experimental Methodology

Closed-die forging produced automotive gear specimens under controlled conditions: initial forging temperature 1150°C, final forging temperature 800°C, and deformation degree 8.6%. Six heat treatment protocols were applied:

| Sample | Process | Temp (°C) | Duration (hr) |

|---|---|---|---|

| 1#-5# | Conventional Annealing | 800-880 | 2.5 |

| 6# | Isothermal Annealing | 860→650 | 1.0→1.5 |

Wear testing employed THT tribometer under 100N load and 120mm/min sliding velocity. Wear volume quantification used:

$$V_w = A \int_{0}^{t} v \, dt$$

where \(A\) is contact area, \(v\) is sliding speed, and \(t\) is duration. Tensile properties were evaluated using BDL-500L tester at 1mm/s strain rate, measuring ultimate tensile strength (σUTS), yield strength (σYS), and elongation (δ).

3. Performance Analysis of Automotive Gear Specimens

Wear volume measurements revealed distinct performance differences between conventional and isothermal annealing:

| Sample | Annealing Temp (°C) | Wear Volume (10-3 mm³) | Reduction vs 800°C (%) |

|---|---|---|---|

| 1# | 800 | 31.8 | – |

| 4# | 860 | 17.1 | 46.2 |

| 5# | 880 | 21.5 | 32.4 |

| 6# | 860→650 | 11.8 | 62.9 |

The relative wear resistance improvement for isothermal annealing is expressed as:

$$R_w = \frac{V_{conv} – V_{iso}}{V_{conv}} \times 100\% = 31\% \text{ vs optimal conventional}$$

SEM analysis confirmed isothermal annealing produced shallower abrasion grooves and minimal delamination in automotive gear surfaces.

4. Mechanical Property Enhancement

Tensile testing demonstrated isothermal annealing’s superiority in strengthening automotive gear components:

| Property | Conventional (860°C) | Isothermal | Improvement (%) |

|---|---|---|---|

| σUTS (MPa) | 895 | 1023 | 14.3 |

| σYS (MPa) | 635 | 721 | 13.5 |

| δ (%) | 18.2 | 15.8 | -13.2 |

The strength-ductility tradeoff follows:

$$\sigma_y \propto d^{-1/2}$$

where \(d\) is grain size. Isothermal annealing refined pearlite colonies by 32% compared to conventional treatment, explaining the strength enhancement despite reduced elongation. Fractography revealed finer, deeper dimples in isothermally annealed automotive gear specimens, indicating modified fracture mechanisms.

5. Conclusion

Isothermal annealing significantly enhances automotive gear performance through microstructural refinement. The 860°C → 650°C two-stage process reduces wear volume by 31-63% versus conventional annealing while increasing tensile strength by 13-14%. These improvements stem from homogeneous pearlite distribution and suppressed proeutectoid ferrite formation. Implementation of isothermal annealing in automotive gear manufacturing will substantially improve service life and operational reliability in vehicular transmission systems.