In modern manufacturing, gear hobbing is one of the most widely used processes for producing gears, especially in applications such as automotive transmissions, aerospace systems, and heavy machinery. The advent of high-speed dry gear hobbing has revolutionized this field by eliminating the need for cutting fluids, thereby promoting environmentally friendly and efficient production. As a researcher in this domain, I have extensively studied the optimization of process parameters to enhance performance metrics like tool life, machining accuracy, and energy efficiency. This article delves into the key aspects of high-speed dry gear hobbing, including the underlying principles, optimization variables, objective functions, constraints, simulation techniques, and advanced optimization methods. By integrating empirical data and computational models, I aim to provide a comprehensive guide for improving gear hobbing processes, with a focus on practical applications and future trends.

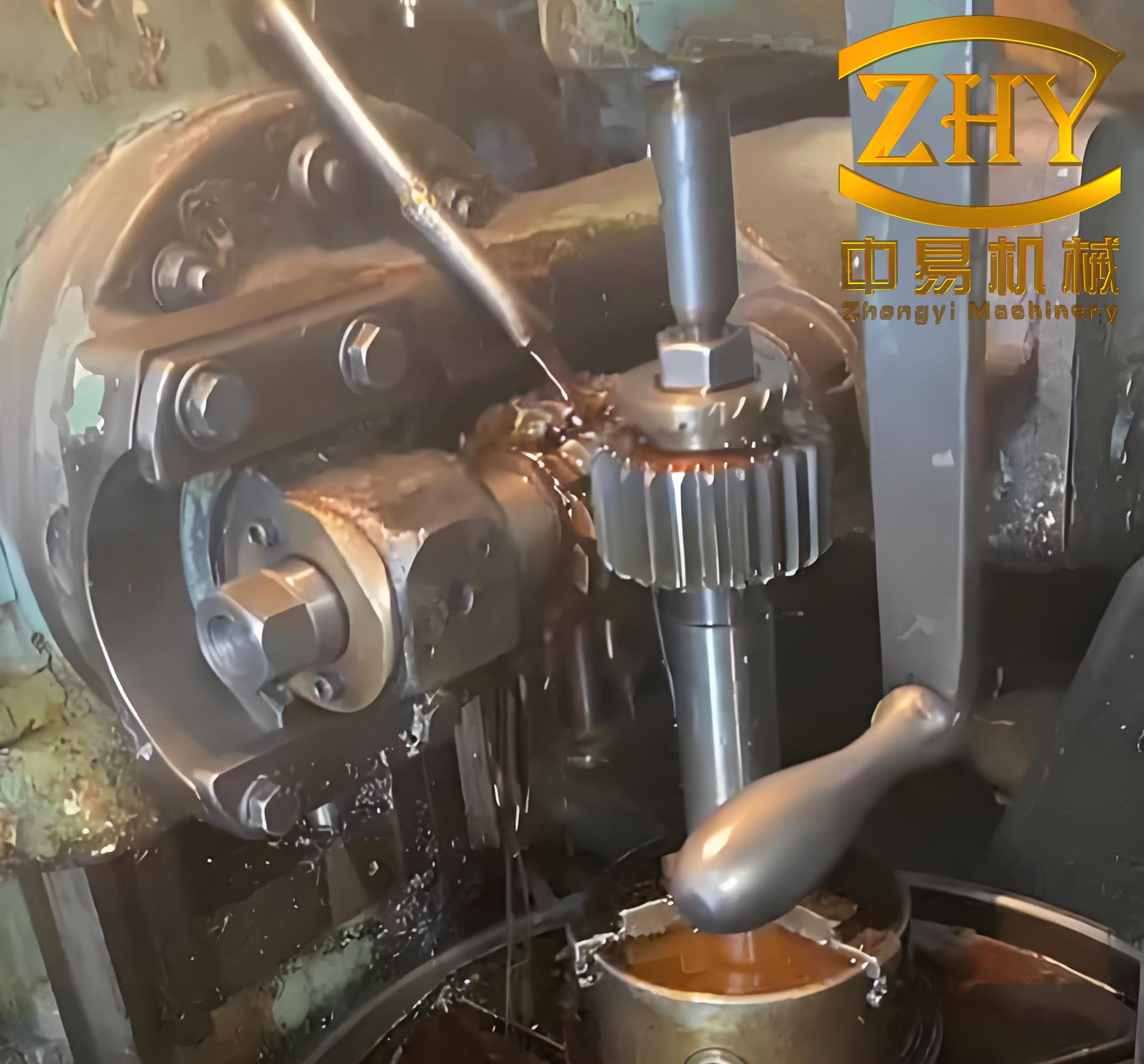

The fundamental principle of gear hobbing involves a generating motion where a hob tool, which resembles a helical gear, engages with a workpiece to form gear teeth through a series of coordinated movements. In high-speed dry gear hobbing, the process operates at elevated cutting speeds without coolant, relying on efficient heat dissipation through chips. The primary motions include the rotation of the hob (main motion), the rotational movement of the workpiece (indexing motion), and the axial feed of the hob. These motions must be precisely synchronized to achieve the desired tooth profile. The absence of cutting fluid in dry gear hobbing reduces environmental impact and operational costs but introduces challenges such as increased thermal loads and tool wear. Thus, understanding the kinematics and dynamics of the gear hobbing machine is crucial for parameter optimization.

Optimization variables in high-speed dry gear hobbing encompass a range of factors that influence the process outcomes. These can be categorized into tool-related parameters, workpiece material properties, machine settings, and cutting conditions. For instance, the hob diameter, number of starts, helix angle, and coating material significantly affect tool life and surface quality. Workpiece materials like 40Cr steel or 20CrMnTi exhibit different machinability characteristics, necessitating tailored parameter sets. The gear hobbing machine’s capabilities, such as spindle speed range and rigidity, also play a pivotal role. Cutting parameters, including cutting speed (\(v_c\)), feed rate (\(f\)), and depth of cut (\(a_p\)), are directly adjustable and have a profound impact on efficiency and quality. Table 1 summarizes the key optimization variables and their typical ranges based on industrial practices and research findings.

| Category | Variable | Description | Typical Range |

|---|---|---|---|

| Tool Parameters | Hob diameter (\(d_{a0}\)) | Diameter of the hob tool | 50–200 mm |

| Number of starts (\(z_0\)) | Number of thread starts on the hob | 1–5 | |

| Coating type | Material coating (e.g., TiN, AlCrN) | – | |

| Workpiece Material | Material grade | Type of steel or alloy | e.g., 40Cr, 20CrMnTi |

| Hardness | Material hardness (HRC) | 20–45 HRC | |

| Machine Parameters | Spindle speed (\(n\)) | Rotational speed of the hob | 1000–5000 rpm |

| Axial feed (\(f_a\)) | Feed rate along the gear axis | 0.1–2.0 mm/rev | |

| Power rating | Machine motor power | 5–30 kW | |

| Cutting Parameters | Cutting speed (\(v_c\)) | Surface speed at the hob periphery | 100–300 m/min |

| Feed per tooth (\(f_z\)) | Feed amount per hob tooth | 0.05–0.3 mm/tooth | |

| Depth of cut (\(a_p\)) | Radial engagement depth | 1–10 mm |

The selection of optimization objectives is critical for achieving a balanced performance in gear hobbing. Common goals include minimizing machining time, reducing production costs, lowering energy consumption, and improving gear accuracy. For example, the machining time (\(t_m\)) for a single gear can be expressed as a function of hob diameter, axial feed, and other parameters. A simplified model is given by:

$$ t_m = \frac{L_c}{v_f} $$

where \(L_c\) is the total cutting path length, and \(v_f\) is the feed velocity. In high-speed dry gear hobbing, \(L_c\) depends on the gear geometry and hob kinematics, often calculated as:

$$ L_c = \pi \cdot d_{a0} \cdot z \cdot \left( \frac{B}{f_a} + \frac{a_p}{\tan(\alpha)} \right) $$

where \(B\) is the face width of the gear, \(z\) is the number of gear teeth, and \(\alpha\) is the pressure angle. Production cost (\(C\)) is another vital objective, incorporating tool costs, machine time, and energy expenses. A typical cost model is:

$$ C = C_m \cdot t_m + \frac{C_{t0} + k \cdot (C_1 + C_2)}{(k+1) \cdot N} $$

Here, \(C_m\) is the machine cost per unit time, \(C_{t0}\) is the initial tool cost, \(k\) is the number of regrinding cycles, \(C_1\) and \(C_2\) are regrinding and recoating costs, and \(N\) is the number of gears produced per tool life. Energy consumption (\(E\)) is increasingly important for sustainable manufacturing and can be modeled as the sum of fixed and variable components:

$$ E = P_{\text{base}} \cdot t_{\text{total}} + \int_0^{t_m} P_{\text{cut}}(t) \, dt $$

where \(P_{\text{base}}\) is the base power of the gear hobbing machine, \(t_{\text{total}}\) is the total machining time, and \(P_{\text{cut}}\) is the cutting power, which varies with parameters like cutting speed and feed rate. Gear accuracy objectives often focus on minimizing errors such as profile deviation (\(\delta_y\)) and helix deviation (\(\delta_x\)), which are influenced by thermal deformation and tool wear. Multi-objective optimization aims to find Pareto-optimal solutions that balance these conflicting goals, as illustrated in Table 2, which compares different objective functions and their implications.

| Objective | Mathematical Formulation | Key Influencing Parameters | Optimization Goal |

|---|---|---|---|

| Machining Time | \( t_m = f(v_c, f, a_p) \) | Cutting speed, feed rate | Minimize |

| Production Cost | \( C = g(t_m, T, L) \) | Tool life, machine time | Minimize |

| Energy Consumption | \( E = h(P_{\text{cut}}, t_m) \) | Spindle speed, feed rate | Minimize |

| Gear Accuracy | \( \delta = j(\delta_x, \delta_y) \) | Thermal effects, tool wear | Minimize errors |

| Tool Life | \( L = k(v_c, f) \) | Cutting speed, feed per tooth | Maximize |

Constraints in high-speed dry gear hobbing arise from limitations of the gear hobbing machine, tool integrity, and quality requirements. For instance, the cutting force must not exceed the machine’s maximum thrust capacity to avoid damage. The power consumption should remain within the motor’s rated capacity, expressed as:

$$ P_{\text{cut}} \leq P_{\text{max}} $$

where \(P_{\text{cut}}\) can be estimated using empirical models like:

$$ P_{\text{cut}} = k_c \cdot a_p \cdot f \cdot v_c $$

with \(k_c\) being a specific cutting force coefficient. Tool life constraints ensure that the hob wear does not surpass a critical threshold, often modeled using Taylor’s equation:

$$ v_c \cdot T^n = C $$

where \(T\) is the tool life, and \(n\) and \(C\) are constants. Surface finish requirements impose limits on feed rates and cutting speeds, while thermal constraints prevent overheating that could degrade the workpiece material. Additionally, geometric constraints related to the gear hobbing machine, such as maximum hob diameter and workspace limits, must be considered. These constraints form a feasible region for parameter optimization, ensuring practical and sustainable operations.

Finite element simulation plays a pivotal role in analyzing and optimizing high-speed dry gear hobbing processes. By modeling the complex interactions between the hob, workpiece, and machine, simulations provide insights into cutting forces, temperature distributions, and stress fields. For example, using software like Deform-3D or ABAQUS, I have simulated the chip formation process, which reveals the impact of parameters on tool wear and surface integrity. The thermal-mechanical coupling in dry gear hobbing is critical due to the absence of coolant, and simulations help predict heat generation and dissipation. A typical temperature field simulation might involve solving the heat transfer equation:

$$ \rho c_p \frac{\partial T}{\partial t} = \nabla \cdot (k \nabla T) + \dot{q} $$

where \(\rho\) is density, \(c_p\) is specific heat, \(k\) is thermal conductivity, and \(\dot{q}\) is the heat generation rate from cutting. Simulation results, such as those showing chip morphology and tool temperature, validate empirical models and guide parameter selection. For instance, optimizing cutting speed and feed rate based on simulated stress distributions can reduce tool wear and improve gear accuracy. Moreover, advanced simulations incorporate wear models to estimate tool life, enabling proactive parameter adjustments in the gear hobbing machine.

Various optimization methods have been applied to high-speed dry gear hobbing, ranging from traditional algorithms to artificial intelligence techniques. Multi-objective evolutionary algorithms (MOEAs), such as NSGA-II (Non-dominated Sorting Genetic Algorithm II), are popular for handling conflicting objectives like minimizing cost and maximizing tool life. The NSGA-II algorithm operates by maintaining a population of solutions and using non-dominated sorting and crowding distance to evolve toward Pareto-optimal fronts. For a problem with objectives \(f_1\) (tool life), \(f_2\) (machining time), and \(f_3\) (cost), the optimization can be formulated as:

$$ \min \left( -f_1(\mathbf{x}), f_2(\mathbf{x}), f_3(\mathbf{x}) \right) \quad \text{subject to} \quad \mathbf{x} \in \mathcal{F} $$

where \(\mathbf{x}\) is the vector of optimization variables (e.g., \(v_c\), \(f\), \(a_p\)), and \(\mathcal{F}\) is the feasible region defined by constraints. Other methods, like particle swarm optimization (PSO) and simulated annealing, have been used for single-objective cases, such as minimizing energy consumption. Recently, data-driven approaches combining neural networks with optimization algorithms have shown promise. For example, a backpropagation neural network can predict tool life based on historical data, and an optimizer like flower pollination algorithm (FPA) can find the best parameters. Table 3 compares different optimization methods, highlighting their strengths and applications in gear hobbing.

| Method | Type | Key Features | Applicability |

|---|---|---|---|

| NSGA-II | Multi-objective evolutionary | Handles multiple goals, Pareto fronts | Balancing cost, time, and accuracy |

| PSO | Population-based | Fast convergence, simple implementation | Energy minimization |

| Simulated Annealing | Single-objective stochastic | Escapes local optima | Tool life optimization |

| FPA with Neural Networks | Hybrid data-driven | Adapts to process variations | Parameter decision-making |

| Gradient-Based Methods | Deterministic | Requires differentiable models | Constrained optimization |

In conclusion, the optimization of high-speed dry gear hobbing process parameters is essential for achieving efficient, cost-effective, and sustainable manufacturing. Through my research, I have demonstrated that a holistic approach, integrating simulation, empirical models, and advanced algorithms, can significantly enhance performance metrics. The gear hobbing machine serves as the core of this process, and its parameters must be carefully tuned to balance competing objectives. Future work should focus on developing real-time adaptive optimization systems that leverage IoT and AI for dynamic parameter adjustment. Additionally, exploring the interplay between tool coatings and cutting parameters could further extend tool life in dry gear hobbing. As industries move toward greener practices, optimizing energy consumption and carbon footprint will become increasingly important. By addressing these challenges, we can unlock the full potential of high-speed dry gear hobbing, paving the way for smarter and more environmentally friendly gear production.

Looking ahead, several trends are poised to shape the future of gear hobbing optimization. The integration of digital twins—virtual replicas of physical gear hobbing machines—will enable continuous monitoring and optimization based on real-time data. Advances in material science may introduce new workpiece alloys and tool coatings that enhance machinability under dry conditions. Moreover, the adoption of machine learning for predictive maintenance can reduce downtime and improve reliability. Collaborative research between academia and industry will be crucial to validate optimization models in practical settings, ensuring that theoretical advancements translate into tangible benefits. As a proponent of sustainable manufacturing, I believe that high-speed dry gear hobbing, when optimized effectively, will play a key role in reducing the ecological impact of gear production while maintaining high quality and efficiency.