In my extensive experience within the heavy manufacturing sector, I have witnessed firsthand the transformative impact of systematic process optimization, particularly in the production and maintenance of critical components like gear shafts. The principles of operation conversion time, which focus on distinguishing between internal and external setup activities to minimize downtime, have proven invaluable. By analyzing and re-engineering tasks—such as roll changes in rolling mills—we successfully converted internal setups to external ones, drastically reducing changeover times. This philosophy extends seamlessly to the fabrication and repair of high-strength gear shafts, where meticulous planning in welding and热处理 processes is paramount to avoiding costly failures and ensuring operational efficiency.

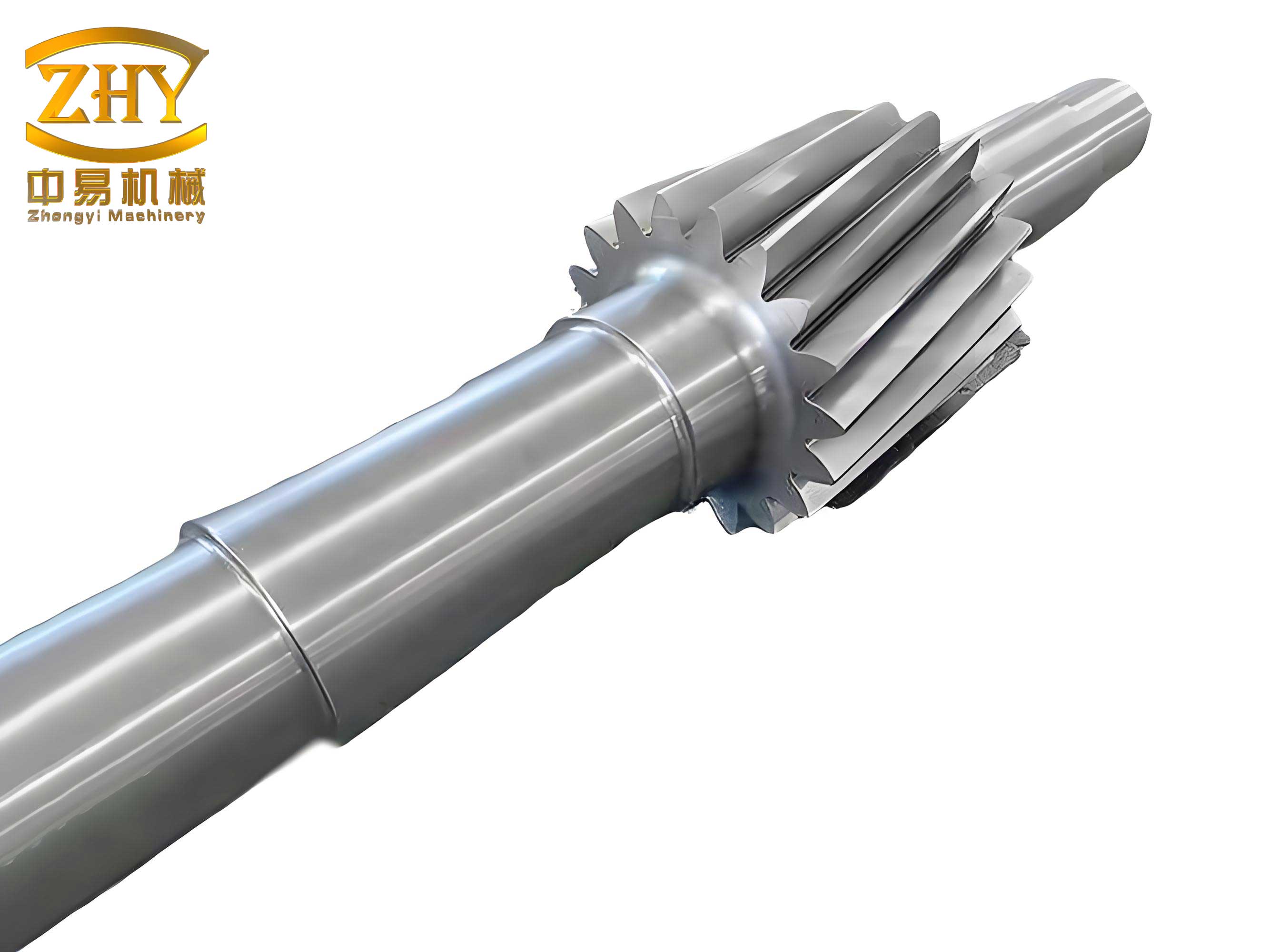

Gear shafts are fundamental power transmission elements in industries ranging from metallurgy to energy. Their failure, often due to wear, fatigue, or machining errors, can lead to significant production losses. Therefore, developing robust repair and manufacturing protocols is essential. A prime example is the welding repair of medium-carbon quenched and tempered steel gear shafts, such as those made from 42CrMo. This steel offers high strength but presents considerable welding challenges due to its composition and hardenability. In our operations, we have applied a structured approach to overcome these hurdles, ensuring that gear shafts maintain integrity under load.

The welding performance of 42CrMo steel for gear shafts is primarily governed by its high carbon equivalent (Ceq), which increases susceptibility to cracks. The carbon equivalent can be estimated using various formulas; one common international standard formula is:

$$C_{eq} = C + \frac{Mn}{6} + \frac{Cr + Mo + V}{5} + \frac{Ni + Cu}{15}$$

For 42CrMo, typical composition ranges yield a Ceq value approximately 0.85% to 0.90%. This high value indicates poor weldability, as it promotes the formation of hard, brittle martensitic structures in the heat-affected zone (HAZ), leading to cold cracking. Cold cracks, often delayed, arise from a combination of factors: hydrogen diffusion, residual stresses, and material hardenability. The critical cooling time to avoid martensite formation, denoted as tcr, must be exceeded by the actual cooling time t100. This relationship is crucial when designing welding procedures for gear shafts.

To mitigate these risks, we have developed a comprehensive welding procedure specification (WPS) for gear shafts. Key elements include welding material selection, preheating, interpass temperature control, and post-weld heat treatment. The selection of welding electrodes is critical. For gear shafts made of 42CrMo, we often use lower-strength matching electrodes, such as E7018 (J507 equivalent), to reduce residual stresses and cracking tendency. Although the weld metal strength may be slightly lower than the base metal, it suffices for many applications, especially when the original design specified a lower-grade steel like 35CrMo. The benefits of this under-matching approach are summarized in the table below.

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Hardness (HB) | Cracking Susceptibility |

|---|---|---|---|---|

| 42CrMo Base Metal | ≥ 980 | ≥ 835 | 280-320 | High |

| E7018 Weld Metal | ≥ 500 | ≥ 410 | 200-240 | Low |

| 35CrMo (Design Reference) | ≥ 700 | ≥ 550 | 220-260 | Medium |

Preheating is indispensable for welding high-strength gear shafts. It slows cooling rates, allowing hydrogen effusion and reducing martensite formation. We determine preheat temperature (T0) using multiple empirical formulas to ensure robustness. For gear shafts with thickness h (in mm), carbon content C, and diffusion hydrogen content [H] in mL/100g, the following equations provide guidance:

$$T_0 = 360 \times C_{eq} \quad \text{(Carbon equivalent method)}$$

$$T_0 = 550 \times (C – 0.12) + 0.4h \quad \text{(Medium-carbon steel formula)}$$

$$T_0 = 324P_{cm} + 17.7[H] + 0.14\sigma_b + 4.72h – 214 \quad \text{(Cracking index formula)}$$

Here, Pcm is the chemical composition cracking sensitivity index: $$P_{cm} = C + \frac{Si}{30} + \frac{Mn + Cu + Cr}{20} + \frac{Ni}{60} + \frac{Mo}{15} + \frac{V}{10}$$ and σb is the base metal tensile strength in MPa. For a typical 42CrMo gear shaft with h=200 mm, C=0.42%, [H]=4 mL/100g, and σb=980 MPa, calculations yield T0 ranging from 250°C to 320°C. In practice, we adopt a conservative approach, preheating gear shafts uniformly to 400°C using furnace heating to account for structural constraints.

During welding, maintaining interpass temperature is critical. We control it within 350±20°C using heating blankets. This minimizes temperature fluctuations that could induce thermal stresses. The welding heat input (Q) is carefully regulated to balance between minimizing HAZ width and avoiding excessive cooling rates. Heat input is calculated as:

$$Q = \frac{60 \times V \times I}{1000 \times S} \quad \text{(in kJ/mm)}$$

where V is voltage (V), I is current (A), and S is travel speed (mm/min). For manual arc welding of gear shafts with Ø5 mm electrodes, we use I=180-220 A, V=23-25 V, and S=180-190 mm/min, resulting in Q≈1.2-1.5 kJ/mm. This moderate heat input helps prevent undue hardening while ensuring proper fusion.

Post-weld heat treatment (PWHT) is applied immediately after welding to relieve residual stresses and facilitate hydrogen removal. We employ stress relief annealing at 600-650°C, with holding time based on thickness: typically 1 hour per 25 mm, but not less than 4 hours for large gear shafts. The cooling rate is controlled at 80°C/h down to 150°C, then air cooling. This cycle effectively reduces hardness in the HAZ and weld metal, enhancing toughness. The table below outlines a typical PWHT schedule for gear shafts of varying sizes.

| Gear Shaft Thickness (mm) | Preheat Temperature (°C) | Interpass Temperature (°C) | PWHT Temperature (°C) | Holding Time (hours) | Cooling Rate (°C/h) |

|---|---|---|---|---|---|

| 100-150 | 380-400 | 330-370 | 600-620 | 4-6 | 80 |

| 150-250 | 400-420 | 340-370 | 620-640 | 6-8 | 80 |

| >250 | 420-450 | 350-370 | 630-650 | 8-10 | 60 |

The efficacy of these procedures is validated through non-destructive testing (NDT) and mechanical tests. For instance, after repairing a 42CrMo gear shaft weighing 2600 kg, we conducted magnetic particle inspection and found no surface cracks. Tensile tests on weld coupons showed strengths matching the E7018 specification, and hardness surveys indicated uniform values below 240 HB, suitable for subsequent machining and service. This demonstrates that with precise control, even high-strength gear shafts can be reliably repaired.

Beyond welding, the principles of operation conversion time have broader implications for gear shaft manufacturing. By analyzing setup processes in machining, heat treatment, and assembly, we identify opportunities to shift internal tasks to external ones. For example, pre-assembling tools and fixtures offline reduces machine downtime during gear shaft production runs. Similarly, predictive maintenance based on lifecycle data—like monitoring furnace lining wear in heat treatment furnaces—allows for planned replacements, minimizing unplanned stoppages. The economic benefits are substantial, as shown in earlier rolling mill optimizations, which can be analogously applied to gear shaft workshops.

Multi-skilled operator training further amplifies these gains. In our context, cross-training welders, machinists, and inspectors fosters flexibility, enabling rapid response to issues in gear shaft production. Employees gain broader competencies, improving job satisfaction and reducing dependency on specialized personnel. This aligns with lean manufacturing tenets, where versatility reduces waste and enhances throughput. For gear shafts, having personnel skilled in both welding and NDT ensures quicker turnaround times for repairs, directly impacting equipment availability.

To quantify the impact of these optimizations on gear shaft production, consider a scenario where annual output is increased through reduced downtime. Suppose a manufacturing line produces 1000 gear shafts per year, with an average downtime of 10 hours per changeover for tooling adjustments. By applying operation conversion time analysis, we can externalize 60% of setup tasks, cutting downtime to 4 hours. The annual increase in productive hours (ΔH) is:

$$\Delta H = N \times (t_{\text{original}} – t_{\text{reduced}})$$

where N is the number of changeovers per year, toriginal and treduced are setup times. If N=50, toriginal=10 h, treduced=4 h, then ΔH = 50 × 6 = 300 hours. Assuming a production rate of 2 gear shafts per hour, this yields an additional 600 gear shafts annually. With each gear shaft valued at $1000, the economic benefit exceeds $600,000, excluding savings in labor and energy.

In conclusion, the integration of operation conversion time principles with advanced welding techniques forms a robust framework for enhancing gear shaft manufacturing and repair. Through meticulous attention to material science, thermal management, and workforce development, we achieve higher reliability, reduced costs, and increased output. The continuous improvement mindset, supported by data-driven formulas and strategic training, ensures that gear shafts meet the demanding standards of modern industry. As technology evolves, further refinements in automation and real-time monitoring will undoubtedly unlock new efficiencies, solidifying the role of gear shafts as indispensable components in mechanical systems.