The planetary roller screw assembly represents a pivotal advancement in precision mechanical transmission systems, renowned for its minimal friction, high efficiency, extended lifespan, and superior load-bearing capacity. As a key component in applications ranging from CNC machine tools and industrial robotics to aerospace and medical devices, the optimization of its structural parameters is essential to enhance performance, reduce costs, and streamline design processes. In this analysis, I will delve into the transmission principles, parameter determination, and multi-objective optimization techniques applied to the planetary roller screw assembly, employing methodologies such as the multiplication-division approach and simulated annealing algorithm to achieve optimal design outcomes.

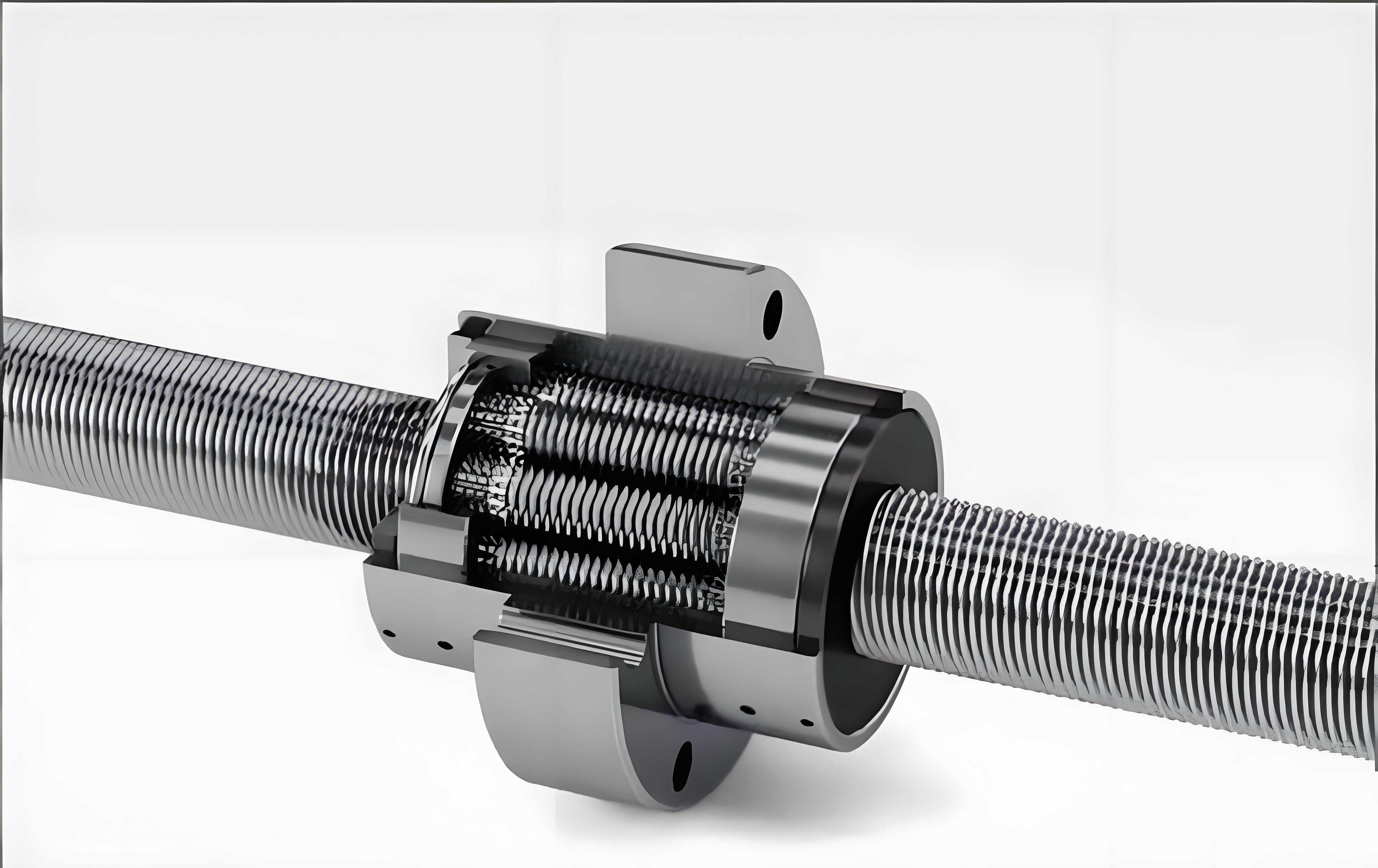

At its core, the planetary roller screw assembly functions as a sophisticated mechanical system where a screw acts as the sun gear, rollers serve as planetary gears, and the nut operates as the ring gear. This configuration enables the conversion of rotary motion into linear displacement with exceptional precision and reliability. The integration of gears at both ends of the rollers ensures synchronized engagement and pure rolling at the pitch circle, mitigating interference caused by individual roller slippage. Understanding these mechanics is fundamental to optimizing the planetary roller screw assembly for diverse operational demands.

The planetary roller screw assembly can be classified based on axial movement, installation methods, length combinations, and precision capabilities. For instance, standard types maintain no axial movement between rollers and the nut, while differential types restrict axial motion relative to the screw. These variations influence design parameters and optimization strategies. In my analysis, I focus on assemblies where gears are directly milled onto the roller threads, as this enhances stiffness, precision, and manufacturability. The structural parameters of these gears are critical to the overall performance of the planetary roller screw assembly.

To determine the basic dimensions of the planetary roller screw assembly, I start with the motion and engagement conditions. The relationship between the screw and roller diameters is derived from the requirement for near-slip-free operation between the nut and screw. Given the screw’s lead number \( n \), the roller diameter \( d_r \) and screw diameter \( d_s \) satisfy:

$$ d_s / d_r = n – 2 $$

Additionally, based on planetary motion principles, the nut diameter \( d_n \) relates to the roller diameter through gear ratios:

$$ d_n / d_r = z_n / z_r $$

Here, \( z_n \) and \( z_r \) denote the number of teeth on the nut gear and roller gear, respectively. These equations form the foundation for calculating initial dimensions, but further optimization is necessary to balance multiple performance criteria in the planetary roller screw assembly.

The optimization of the planetary roller screw assembly involves selecting design variables that significantly impact its functionality. I define these variables as the module \( m \), number of teeth on the roller gear \( z_r \), total number of rollers \( C \), profile shift coefficient for the roller gear \( x_1 \), and gear width \( B \). Represented as a vector:

$$ \mathbf{X} = [m, z_r, C, x_1, B]^T = [x_1, x_2, x_3, x_4, x_5]^T $$

These variables are optimized to minimize volume and maximize contact ratio, both crucial for the planetary roller screw assembly’s efficiency and durability. The multi-objective function combines these goals using the multiplication-division method, where the total volume \( f_1(\mathbf{X}) \) is divided by the contact ratio \( f_2(\mathbf{X}) \) to form a unified objective:

$$ f(\mathbf{X}) = \frac{f_1(\mathbf{X})}{f_2(\mathbf{X})} $$

The total volume considers the sun gear (screw) and planetary gears (rollers), expressed as:

$$ f_1(\mathbf{X}) = \frac{1}{4} \pi B \left[ (n-2)^2 + x_3 \right] \left[ \frac{x_1 (x_2 + 2h_a^* + x_4) – S}{L} \right]^2 $$

where \( h_a^* \) is the addendum coefficient, and \( L \) and \( S \) are revision coefficients relating the roller outer diameter to its nominal diameter. The contact ratio, essential for load capacity and smooth operation, is given by:

$$ f_2(\mathbf{X}) = \frac{x_2}{2\pi} \left[ \tan\left(\arccos\left(\frac{x_1 x_2 \cos \alpha}{d_{ra}}\right)\right) – \tan \alpha_1′ \right] – \frac{x_2}{2\pi n} \left[ \tan\left(\arccos\left(\frac{x_1 x_2 \cos \alpha}{d_{na}}\right)\right) – \tan \alpha_2′ \right] $$

with \( d_{ra} = m z_r + 2m(h_a^* + x_1) \) and \( d_{na} = n m z_r – 2m(h_a^* + \Delta h_a^* – x_2) \), where \( \Delta h_a^* \) is an increment to avoid interference, and \( \alpha \) is the pressure angle. This formulation ensures that the planetary roller screw assembly achieves optimal gear engagement.

Constraints are imposed to guarantee structural integrity and performance of the planetary roller screw assembly. These include non-root cutting conditions, avoidance of tooth tip sharpening, geometric conditions for backlash-free meshing, interference prevention, contact strength requirements, width limitations, adjacent roller conditions, and pressure angle ranges. Mathematically, these constraints are expressed as:

1. Module positivity: \( h_1(\mathbf{X}) = -x_1 \leq 0 \)

2. Non-root cutting: \( h_2(\mathbf{X}) = h_a^* – x_2 \sin^2 \alpha / 2 – x_4 \leq 0 \)

3. Tooth tip thickness: \( 0.4 – d_{ra} \left[ \text{inv}\left(\arccos\left(\frac{x_1 x_2 \cos \alpha}{d_{ra}}\right)\right) – \text{inv} \alpha – \left( \frac{\pi}{2x_2} + \frac{2x_4}{x_2} \tan \alpha \right) \right] \leq 0 \) and a similar condition for \( d_{na} \).

4. Backlash-free meshing: \( h_5(\mathbf{X}) = x_{\Sigma} = x_2 – x_1 = \frac{(n-1)x_2 (\text{inv} \alpha’ – \text{inv} \alpha)}{2 \tan \alpha} \)

5. Non-interference: \( \tan \alpha – \frac{4(h_a^* – x_4)}{x_2 \sin 2\alpha} – \tan \alpha’ + n \tan\left(\arccos\left(\frac{x_1 x_2 \cos \alpha}{d_{na}}\right)\right) – n \tan \alpha’ \leq 0 \) and its counterpart.

6. Contact strength: \( K_A K_\beta \sqrt{\frac{2K T_n}{x_2^2 x_5 x_1^2 (n-2)(n-1)}} – [\sigma]_N \leq 0 \) and a similar expression for bending strength.

7. Width limits: \( x_5 – 0.35 x_1 x_2 (1 + n) \leq 0 \) and \( 0.2 x_1 x_2 (1 + n) – x_5 \leq 0 \).

8. Adjacent roller condition: \( [x_1 x_2 + 2x_1(h_a^* + x_4)] – (n+1) x_1 x_2 \sin \frac{\pi}{x_3} \leq 0 \).

9. Pressure angle range: \( \alpha’ – 25^\circ \leq 0 \) and \( 17^\circ – \alpha’ \leq 0 \).

These constraints ensure that the optimized planetary roller screw assembly meets practical design standards while enhancing performance.

To solve this multi-objective optimization problem for the planetary roller screw assembly, I employ the simulated annealing algorithm, a heuristic method effective for discrete variables. Unlike conventional optimization techniques, simulated annealing explores the design space by accepting worse solutions probabilistically to escape local optima, ultimately converging to a global optimum. The algorithm is adapted for discrete variables, where design parameters like module and tooth number take specific values. The state generation function for discrete variables is defined as:

For general discrete variables: \( x = X[\text{Int}((n-1) \cdot \text{Rnd}() + 1)] \), where \(\text{Rnd}()\) generates a random number in \([0,1]\).

For pseudo-discrete variables in interval \([a,b]\) with increment \(k\): \( x = \text{Int}\left\{ \frac{1}{k} [(b-a) \cdot \text{Rnd}() + a] \right\} \cdot \frac{1}{k} \).

This approach allows the optimization of the planetary roller screw assembly to account for manufacturing constraints, such as standard module sizes and integer tooth counts, ensuring practical feasibility.

The application of this optimization methodology to a specific planetary roller screw assembly yields significant improvements. Consider an assembly with the following base parameters:

| Parameter | Value |

|---|---|

| Nominal screw diameter | 20 mm |

| Lead | 1.2 mm |

| Nut outer diameter | 42 mm |

| Number of screw starts | 5 |

Using the optimization framework, the gear parameters are refined as shown in the tables below. The initial and optimized values demonstrate how the planetary roller screw assembly benefits from increased tooth counts and adjusted dimensions, enhancing the contact ratio and overall stiffness.

| Parameter | Initial Value | Optimized Value |

|---|---|---|

| Number of teeth \( z_r \) | 12 | 13 |

| Number of rollers \( C \) | 8 | 9 |

| Gear width \( B \) (mm) | 5 | 4.5 |

| Module \( m \) (mm) | 0.5 | 0.5 |

| Profile shift coefficient \( x_1 \) | 0.28 | 0.25 |

| Parameter | Initial Value | Optimized Value |

|---|---|---|

| Number of teeth \( z_n \) | 60 | 65 |

| Number of rollers \( C \) | 8 | 9 |

| Gear width \( B \) (mm) | 5 | 5 |

| Module \( m \) (mm) | 0.5 | 0.5 |

| Profile shift coefficient \( x_2 \) | 0.28 | 0.25 |

The optimization results indicate a higher contact ratio due to increased tooth numbers and roller count, which improves the load distribution and operational smoothness of the planetary roller screw assembly. The slight reduction in gear width for the roller gear contributes to volume minimization without compromising strength, aligning with the multi-objective goals. This outcome underscores the efficacy of the simulated annealing algorithm in handling discrete design variables for the planetary roller screw assembly.

Further analysis of the planetary roller screw assembly involves evaluating the impact of optimization on dynamic performance and fatigue life. The contact ratio, a key metric, can be expressed in terms of the design variables to assess improvements. For the optimized parameters, the contact ratio \( \varepsilon \) is calculated as:

$$ \varepsilon = \frac{1}{2\pi} \left[ z_r (\tan \alpha_{ar} – \tan \alpha’) + z_n (\tan \alpha_{an} – \tan \alpha’) \right] $$

where \( \alpha_{ar} \) and \( \alpha_{an} \) are the tip pressure angles for the roller and nut gears, respectively. With optimized values, \( \varepsilon \) increases, reducing stress concentrations and enhancing the longevity of the planetary roller screw assembly. Additionally, the volume minimization objective reduces material usage and weight, critical for aerospace and robotic applications where the planetary roller screw assembly is often deployed.

The simulated annealing algorithm’s parameters, such as initial temperature, cooling rate, and iteration count, play a vital role in optimizing the planetary roller screw assembly. I typically set an initial temperature \( T_0 = 1000 \), a cooling factor \( \alpha = 0.95 \), and a stopping criterion based on minimal improvement over iterations. The acceptance probability follows the Metropolis criterion:

$$ P = \exp\left( -\frac{\Delta f}{T} \right) $$

where \( \Delta f \) is the change in the objective function value. This stochastic approach ensures thorough exploration of the design space for the planetary roller screw assembly, avoiding premature convergence to suboptimal solutions.

In practice, the optimization of the planetary roller screw assembly must also consider manufacturing tolerances and assembly constraints. For instance, the gear teeth milled on rollers require precise machining to maintain the profile shift coefficients and avoid deviations that could affect meshing. The tables below summarize additional derived parameters post-optimization, highlighting key geometric attributes.

| Parameter | Roller Gear | Nut Gear |

|---|---|---|

| Pitch diameter (mm) | \( d_r = m z_r = 6.5 \) | \( d_n = m z_n = 32.5 \) |

| Addendum diameter (mm) | \( d_{ra} = m z_r + 2m(h_a^* + x_1) = 7.4 \) | \( d_{na} = m z_n – 2m(h_a^* + \Delta h_a^* – x_2) = 31.6 \) |

| Contact ratio \( \varepsilon \) | 1.78 (optimized vs. 1.65 initial) | |

| Volume reduction (%) | Approximately 12% compared to initial design | |

These results demonstrate that the optimized planetary roller screw assembly achieves a balance between compactness and performance. The increased contact ratio directly translates to higher load capacity and smoother motion transmission, essential for applications like medical devices where precision is paramount. Moreover, the reduction in volume aligns with lightweight design trends, making the planetary roller screw assembly more competitive in markets demanding efficiency and cost-effectiveness.

The optimization process for the planetary roller screw assembly can be extended to include other performance metrics, such as thermal expansion effects, lubrication requirements, and noise reduction. For example, the gear width \( B \) influences heat dissipation and wear characteristics. A narrower width may reduce friction but could increase contact stress, necessitating trade-offs that the multi-objective function captures. Future work on the planetary roller screw assembly might incorporate finite element analysis to validate stress distributions under dynamic loads, further refining the optimization constraints.

In conclusion, the structural parameter optimization of the planetary roller screw assembly through the multiplication-division method and simulated annealing algorithm offers a robust framework for enhancing design quality while curtailing development time and expenses. By treating key variables as discrete entities and imposing realistic constraints, this approach yields practical solutions that improve contact ratio, minimize volume, and ensure reliable operation. The planetary roller screw assembly, as a critical component in advanced mechanical systems, benefits significantly from such optimization, paving the way for its continued adoption in high-performance industries. As technology evolves, further refinements in optimization algorithms and material science will undoubtedly unlock new potentials for the planetary roller screw assembly, driving innovation in precision engineering.