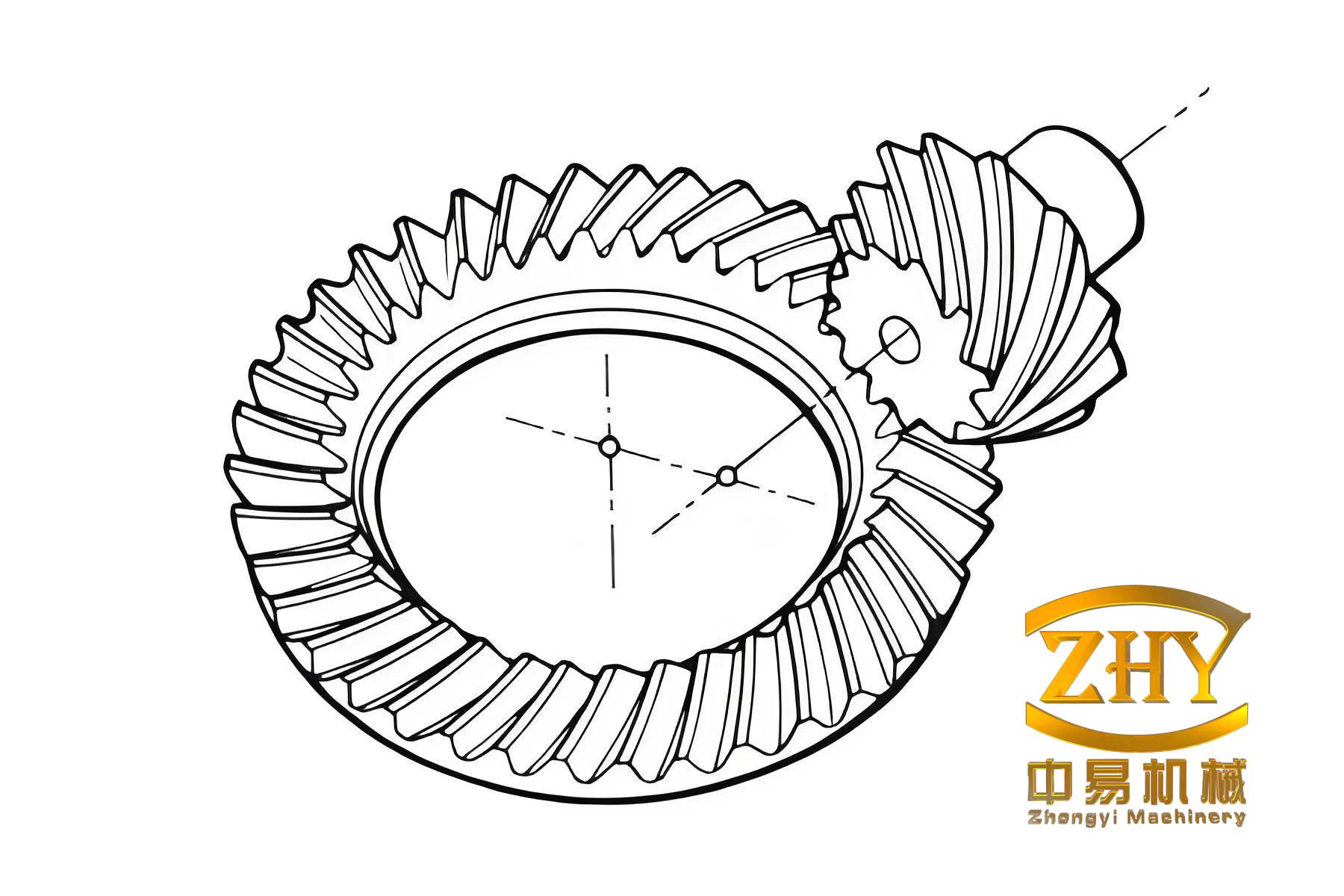

In my experience working with advanced drivetrain systems, the hypoid gear stands out as a critical and sophisticated component, especially in automotive final drive applications. The unique offset configuration of the hypoid gear pair allows for lower propeller shaft placement and higher torque capacity, making it indispensable in modern vehicle design. However, achieving the desired meshing quality—encompassing contact pattern location and size, transmission error characteristics, and lubrication flow—is a profound challenge. The geometry of a hypoid gear is exceedingly complex, and traditionally, determining the optimal machine-tool settings for its manufacture has been more an art than a science, relying heavily on empirical adjustment cards and extensive trial-and-error cutting.

The conventional approach, while established, is computationally intensive and opaque, requiring hundreds of formulas. It offers little direct control over the final meshing performance, often necessitating multiple test cuts and adjustments guided by seasoned experience. This process is time-consuming, costly, and a significant bottleneck in achieving consistent, high-quality gear production. Throughout my research, I have focused on overcoming this fundamental limitation by implementing a more scientific and direct methodology known as local synthesis.

The core philosophy of local synthesis is to pre-specify the key meshing characteristics at a chosen reference point on the gear tooth flank. By mathematically linking these desired conditions directly to the principal curvatures and directions of the tooth surface, one can reverse-engineer the required cutting parameters in a single, coherent calculation. This method shifts the paradigm from iterative testing to predictive design, ensuring that the manufactured hypoid gear pair exhibits the exact performance attributes required for smooth operation, durability, and low noise. The process hinges on analyzing the contact conditions between two surfaces, which I will now elaborate on.

Fundamental Theory: The Local Synthesis Method

The local synthesis method is grounded in differential geometry and the theory of gearing. Consider two surfaces, $\Sigma_1$ and $\Sigma_2$, in continuous tangency at a point $M$. The essential parameters describing their contact are the principal curvatures and principal directions on each surface at $M$. For a pair of gears, their relative motion (speeds, transmission ratio) and the geometry of the tool (which generates one gear surface) are known or chosen. The goal is to determine the geometry of the mating gear surface such that specific contact conditions are met.

At the contact point $M$, let $\vec{n}$ be the common unit normal. Let $\vec{e}_1^{(1)}$ and $\vec{e}_2^{(1)}$ be the principal direction vectors on $\Sigma_1$, and $\vec{e}_1^{(2)}$ and $\vec{e}_2^{(2)}$ on $\Sigma_2$. The angle between $\vec{e}_1^{(1)}$ and $\vec{e}_1^{(2)}$ is denoted by $\sigma$. The fundamental relationship governing the surface curvatures and the kinematics is given by the following matrix equation derived from the conditions of continuous tangency and the equation of meshing:

$$ \begin{bmatrix}

\kappa_1^{(1)} – \kappa_1^{(2)} & 0 & -\sin\sigma \\

0 & \kappa_2^{(1)} – \kappa_2^{(2)} & \cos\sigma \\

-\sin\sigma & \cos\sigma & 0

\end{bmatrix}

\begin{bmatrix}

v_{r12}^{(e1)} \\

v_{r12}^{(e2)} \\

\omega_{r12}^{(n)}

\end{bmatrix} = 0 $$

Where $\kappa_i^{(j)}$ are the principal curvatures, $v_{r12}^{(ei)}$ are the projections of the relative velocity $\vec{v}_{r12}$ onto the principal directions of $\Sigma_1$, and $\omega_{r12}^{(n)}$ is the component of the relative angular velocity $\vec{\omega}_{r12}$ along the normal $\vec{n}$. The transmission ratio derivative $m_{21}^{(1)}$ is also involved in the full kinematic expressions.

For a hypoid gear set, we distinguish between two scenarios crucial for design:

- Line Contact during Generation: When a gear is being cut by a tool (simulated as a crown gear or generating gear), their theoretical engagement is a line contact. In this case, the rank of the coefficient matrix in the equation above is less than 3. With the tool surface geometry ($\Sigma_t$) and kinematics known, we can solve for the principal curvatures and directions of the generated gear surface ($\Sigma_g$) at $M$.

- Point Contact in Operation: The actual meshing of the finished pinion and gear is a point contact to accommodate misalignment. Here, the matrix rank is 3. If we additionally prescribe the desired conditions—such as the size of the contact ellipse (semi-major axis length $a$), the direction of the contact path relative to a principal direction (angle $\eta$), and the derivative of the transmission function (which controls transmission error parabola)—we can solve for the required principal curvatures and directions on the pinion surface. The contact ellipse size is related to the surface normal curvatures by:

$$ a = \sqrt{\frac{\delta}{|\Delta\kappa_n|}} $$

Where $\delta$ is the composite deformation of the gear teeth under load and $\Delta\kappa_n$ is the relative normal curvature in the direction of the contact ellipse minor axis. The angle $\eta$ directly defines the orientation of the relative velocity vector at the contact point relative to the principal directions.

This mathematical framework allows for a deterministic design flow. The following table summarizes the contrast between the traditional and local synthesis approaches for hypoid gear design:

| Aspect | Traditional (Adjustment Card) Method | Local Synthesis Method |

|---|---|---|

| Design Control | Indirect, via machine settings. | Direct, via prescribed meshing quality parameters. |

| Computational Basis | Hundreds of empirical formulas; iterative. | Systematic differential geometry; single-pass solution. |

| Key Inputs | Basic gear dimensions, blank data. | Reference point data, desired $a$, $\eta$, $m_{21}^{(1)}$. |

| Output Precision | Requires test cuts and corrections. | Yields theoretically correct settings meeting targets. |

| Role of Experience | Critical for successful final adjustment. | Minimized; process is automated and predictable. |

Step-by-Step Optimization Procedure for Hypoid Gears

The application of local synthesis to the cutting design of a hypoid gear pair involves a sequential procedure. I will outline the major steps, incorporating the necessary coordinate transformations and equations.

1. Determination of the Reference Point

The process begins by selecting a reference point $M$ on the gear tooth surface, typically at the mid-face width and mid-height of the tooth. Its position is defined by the distance $L_{p2}$ from the pinion apex along the pitch cone and the offset from the pitch line. The geometry can be derived from basic gear data:

$$ \text{Pitch Angle: } \theta_{p2} $$

$$ \text{Root Angle: } \theta_{f2} = \theta_{p2} – \gamma_{f2} $$

$$ \text{Position from Apex: } \overrightarrow{O_pM} = L_{p2} \cdot \vec{e}_{pitch} $$

Where $\gamma_{f2}$ is the dedendum angle. By adjusting $L_{p2}$ and the radial offset, the location of $M$ can be precisely placed within the desired contact pattern zone on the hypoid gear flank.

2. Calculation of the Gear Cutting Parameters

The gear (typically the larger member) is cut first. Its machine settings are more straightforward and can be initially defined with some freedom. Key settings include the machine center to back ($X_{B2}$), sliding base ($X_{D2}$), cutter radial position ($S_{r2}$), cutter angular position ($q_2$), and the ratio of roll ($i_{02}$). For simplicity, the offset of the generating gear (Vertical Wheel Offset, $E_{M2}$) is often set to zero initially. The basic relational formulas involve the gear’s spiral angle $\beta_{m2}$, pitch cone distance $R_{m2}$, and cutter radius $R_{c0}$:

$$ X_{B2} = R_{m2} \sin \theta_{f2} + L_{p2} \cos \theta_{f2} + \Delta X_{B} $$

$$ S_{r2} = R_{c0} – R_{m2} \cos \beta_{m2} $$

These establish the initial spatial relationship between the gear blank and the imaginary generating gear (the cutter head).

3. Local Synthesis for the Gear Tooth Surface

With the tool geometry (a conical cutter surface $\Sigma_c$) and the kinematic roll relationship between the cradle (tool) and the gear blank known, we apply the line contact condition. The tool surface is defined in its coordinate system $S_c(x_c, y_c, z_c)$ by parameters $\theta_c$ and $u_c$:

$$ \vec{r}_c(u_c, \theta_c) = [u_c \sin \alpha_c \cos \theta_c, \quad u_c \sin \alpha_c \sin \theta_c, \quad -u_c \cos \alpha_c]^T $$

Where $\alpha_c$ is the cutter blade pressure angle. Through a series of coordinate transformations to the machine setting system $S_2$ and applying the equation of meshing $\vec{n}_c \cdot \vec{v}_c^{(c2)} = 0$, we can solve for the specific tool position parameters ($\theta_c^M, u_c^M$) corresponding to point $M$. Subsequently, the unit normal $\vec{n}_2^M$, principal curvatures $\kappa_{1,2}^{(2)}$, and principal directions $\vec{e}_{1,2}^{(2)}$ of the generated gear surface $\Sigma_2$ at $M$ are computed. This completes the full geometric definition of the gear flank at the reference point.

4. Establishing the Meshing Relationship for the Pair

Before designing the pinion, we define the operational meshing relationship between the finished gear and pinion. A fixed coordinate system $S_f$ is attached to the gear housing. The gear and pinion rotate about their axes with angles $\phi_2$ and $\phi_1$, related by the nominal transmission ratio $i_{21}$. The shaft angle $\Sigma$ and offset distance $E$ are key design parameters for the hypoid gear set. The coordinate transformation from the gear system $S_2$ to the pinion system $S_1$ via $S_f$ is:

$$ \vec{r}_1(\phi_1, \phi_2) = M_{1f}(\phi_1) \cdot M_{f2}(\phi_2) \cdot \vec{r}_2 $$

The condition of contact (equation of meshing) must hold:

$$ \vec{n}_2 \cdot \vec{v}_2^{(21)} = 0 $$

This equation, combined with the known surface $\Sigma_2$, allows us to determine the kinematic relationship (angular positions $\phi_1^M, \phi_2^M$) for contact at point $M$, as well as the relative velocity vector $\vec{v}_2^{(21)}$ at that point.

5. Local Synthesis and Cutting Design for the Pinion

This is the critical step where we enforce the desired operational quality. We now have:

- The gear surface geometry ($\kappa_{1,2}^{(2)}, \vec{e}_{1,2}^{(2)}$) at $M$.

- The kinematic data ($\vec{\omega}^{(1)}, \vec{\omega}^{(2)}, \vec{v}^{(21)}$) at $M$.

- Prescribed meshing targets: contact ellipse semi-major axis $a$, path direction angle $\eta$, and transmission ratio derivative $m_{21}^{(1)}$.

We apply the point contact equations of local synthesis. This system of equations, incorporating the relationship for $a$ and $\eta$, is solved for the unknown principal curvatures $\kappa_{1,2}^{(1)}$ and principal directions $\vec{e}_{1,2}^{(1)}$ of the required pinion surface $\Sigma_1$ at $M$.

Finally, we determine the pinion cutting parameters. The pinion is generated by a tool (with known surface $\Sigma_t$) in a separate machine setup. We apply the line contact condition again, but now between the to-be-generated pinion surface $\Sigma_1$ (with its now-known geometry at $M$) and the tool surface $\Sigma_t$. The equation of meshing and the condition for surface tangency provide a system where the unknowns are the pinion’s machine settings: the pinion’s Vertical Wheel Offset ($E_{M1}$), Sliding Base ($X_{D1}$), Cradle Angle ($\phi_{1c}$), and Ratio of Roll ($i_{01}$). Solving this system yields the precise machine-tool settings needed to cut the pinion. For a process without helical motion (like Formate or simple Revacycle), this completes the design. The radial setting for the pinion cutter $S_{r1}$ is then determined from the instantaneous cutter radius at point $M$:

$$ S_{r1} = R_{c1}^M – \sqrt{(X_{D1})^2 + (E_{M1})^2} $$

Where $R_{c1}^M$ is the computed cutter point radius at $M$.

Computational Implementation and Advantages

I have implemented the entire derivation above into a comprehensive computer program. The core algorithm flow is summarized in the following diagram, which outlines the data progression from basic input to final machine settings:

[Start: Basic Gear Data & Targets]

|

v

[1. Define Reference Point M on Gear]

|

v

[2. Choose Initial Gear Cutting Settings]

|

v

[3. Calculate Gear Surface Geometry at M (Line Contact Synthesis)]

|

v

[4. Calculate Meshing Kinematics for Pinion/Gear at M]

|

v

[5. Input Targets: a, η, m' -> Solve for Pinion Surface at M (Point Contact Synthesis)]

|

v

[6. Solve for Pinion Cutting Settings (Line Contact Synthesis)]

|

v

[End: Output Full Set of Machine Settings for Gear & Pinion]

The advantages of this optimized design approach for hypoid gears are substantial:

- Predictive First-Attempt Success: The calculated settings theoretically produce a gear pair with the exact predefined meshing characteristics, drastically reducing the number of required test cuts.

- Explicit Quality Control: Engineers directly specify performance metrics (contact ellipse size, path direction, low transmission error) rather than indirectly manipulating machine settings.

- Automation and Accessibility: The complex mathematics is encapsulated within software, making advanced hypoid gear design accessible without requiring mastery of hundreds of empirical formulas.

- Foundation for Advanced Analysis: The precise mathematical description of the tooth surfaces facilitates subsequent analysis, such as loaded tooth contact analysis (LTCA) and finite element analysis for stress.

Practical Considerations and Future Extensions

While the second-order local synthesis method described provides excellent control over the meshing conditions at the reference point, real-world applications require robustness. Manufacturing errors, assembly misalignments, and load-induced deflections can cause the contact to shift away from the designed point. To improve the insensitivity of the meshing quality to such shifts, the method can be extended to third-order contact analysis. This involves controlling not just curvatures (second-order properties) but also the rate of change of curvature along the tooth surface. Achieving specific third-order conditions usually requires the use of more complex machine adjustments, such as modified roll (helical motion) or a tiltable cutter head (cutter tilt or swivel). The local synthesis framework can be expanded to include these degrees of freedom, solving for modified roll coefficients or tilt angles that optimize the contact behavior over a wider area of the tooth flank.

Furthermore, the integration of this precise geometric design with manufacturing simulation and verification tools creates a closed-loop digital twin for hypoid gear production. The designed surfaces can be used to simulate the grinding or lapping process, further refining the settings to account for tool wear or process-specific deviations.

In conclusion, the optimization of cutting design for hypoid gears through the local synthesis method represents a significant leap from experience-based trial-and-error to a deterministic, science-driven process. By establishing a direct mathematical link between desired operational performance and the required manufacturing parameters, it ensures that the complex geometry of the hypoid gear is faithfully and optimally produced. This methodology not only enhances quality and consistency but also accelerates development cycles, ultimately contributing to more efficient, quieter, and more durable automotive drivetrains. The ability to precisely tailor the contact pattern and transmission error is paramount in meeting the ever-increasing demands for performance and NVH (Noise, Vibration, and Harshness) characteristics in modern vehicles, solidifying the role of the hypoid gear as a high-performance solution in advanced gear design.