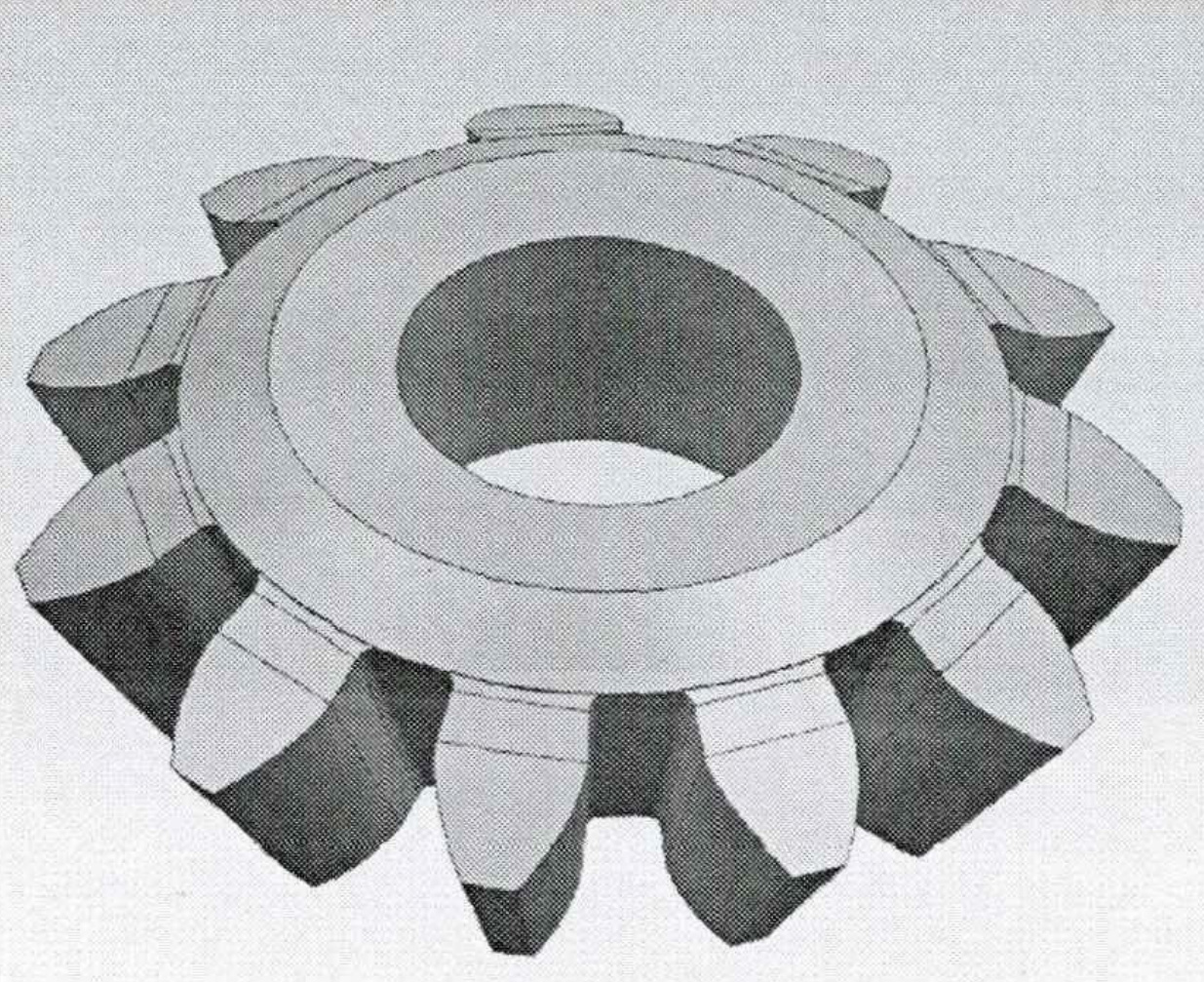

The blank of precision forging straight bevel gear on the friction press is hot-rolled bar. The manufacturing process is that the hot-rolled bar is cut into a fixed length by high-speed band saw, so the equipment for preparing the preform is high-speed band saw.

The cooling of precision die bevel gear forgings is mainly to prevent oxidation during the cooling process of hot forgings. Therefore, it should be cooled in protective medium. The following three methods are usually used to cool hot precision forgings. Generally, bevel gear forgings are put into dry fine sand for cooling. In batch production, forgings are orderly placed in a grid sand box. When the bevel gear forgings need to be cooled slowly, the bevel gear forgings can be cooled in a sand box or asbestos powder. In order to protect the bevel gear forgings more effectively, it can be cooled in the shielding gas device.

The bevel gear forgings forged by the “one fire two forging” process on the friction press are cooled in a sand box.