Forging is a plastic forming processing method, which uses various pressure machines to exert pressure on the metal blank under certain temperature conditions to produce plastic deformation, so as to obtain the required forging.

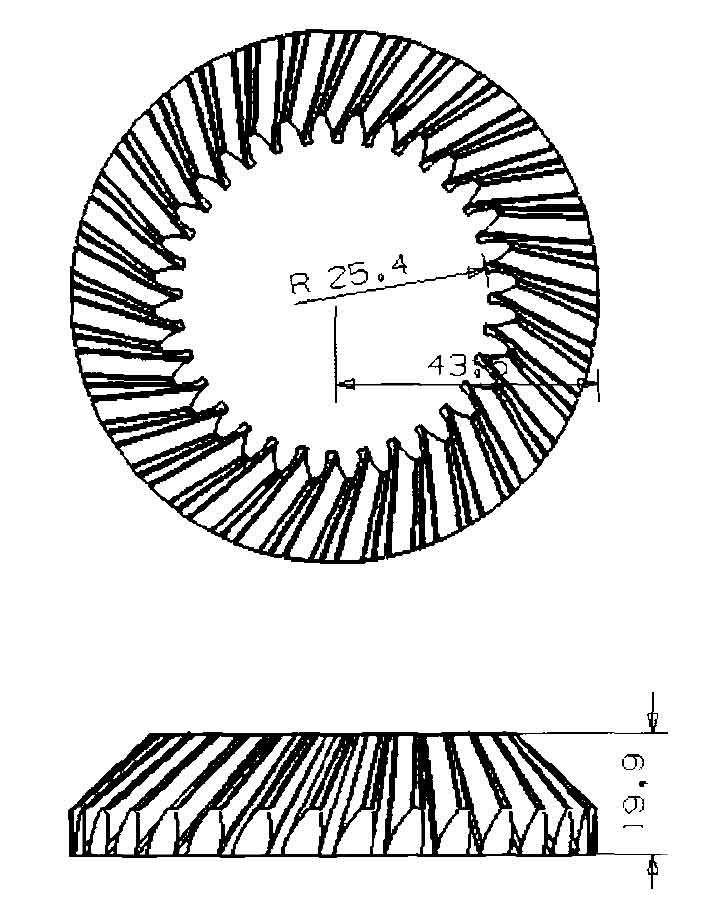

There are two kinds of forging of spiral bevel gear: one is the hot forging of gear blank for subsequent machining, and the other is the precision forging of gear. The precision forging of gear is a method of less and no cutting. The forgings after precision forging do not need subsequent cutting or only a small amount of finishing.

The research of gear forging at home and abroad mainly focuses on the research of gear precision forging.

The research on gear precision forging abroad is earlier and the technology is more advanced. At present, Germany, Japan, the United States and other industrially developed countries are in a leading position in gear precision forging technology. Many foreign experts and scholars have studied the precision forging technology of gears.

K Kondo studied the cold precision forging of gear with boss, and put forward the centripetal and centrifugal flow conditions during cold precision forging of gear; The principle of floating die for precision forging spur gear is put forward. The gear tooth profile forged by this method is fully filled, but this die is not suitable for the situation of large deformation force; At the same time, the shunting principle is proposed for cold precision forging spur gear. Shunting refers to the phenomenon that the direction of metal flow velocity is opposite in the metal deformation area in the forging process. Shunting principle refers to the overflow port set on the non working surface of the gear, so that there will always be material shunting in the forging process, The sudden increase of load in the last stage of block forging process is avoided.

E. Doege and r. bohnsack proposed the method of hot forging spur gear and helical gear with alternating closing device. In the traditional closed die forging, more than 50% of the pressure is only used to close the die without deformation. Their new method can avoid this situation.

Cai J and Dean T.A studied the forging die. They designed the punch as plane and inclined plane, and the die as fixed and floating respectively. They studied the metal flow and required load under different schemes. The results showed that when the inclined punch and floating die were used, the metal filling was the fullest and the forming load was the lowest.