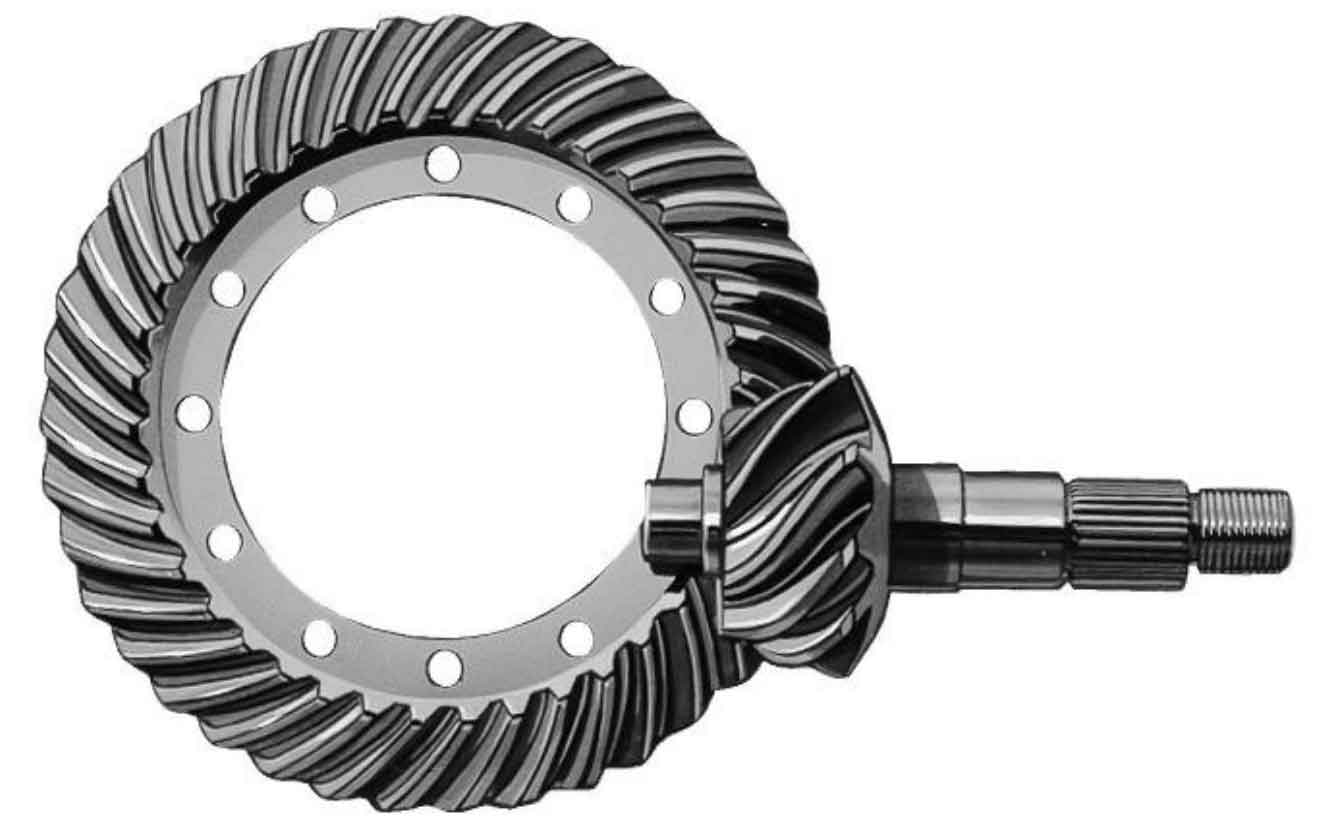

As a special bevel gear, hypoid gear has complex design theory, many technical difficulties and great manufacturing difficulties. In the field of hypoid gear design and manufacturing, domestic technology is relatively backward, the core theory of design and manufacturing is still not fully mastered, and the ability of independent innovation is relatively low. The gear production mainly depends on the purchase of foreign CNC machine tools or imitation machine tools. Due to the large market demand for hypoid gears, it is an inevitable trend for the development of hypoid gears in China to develop high-quality products and build national independent brands. Using the traditional method to complete the design of hypoid gear not only has a long design cycle, but also the quality is difficult to guarantee, which can not meet the needs of products. The research on the new design method of hypoid gear has important theoretical and practical significance. With the development of CAD technology in the mechanical field, the application of advanced design methods and solid modeling software to complete the design requirements is the main trend of mechanical design development. If the interference between the size of the hypoid gear and the assembly process of the hypoid gear can be simulated by the computer, it can not only effectively analyze the interference between the hypoid gear and the hypoid gear, but also improve the efficiency of the whole hypoid gear assembly process, Shorten the design cycle of products.

Due to the powerful function of 3D software Pro / E, the designer can complete 3D design and check the assembly interference to ensure the rationality of design and processing technology. Therefore, it has been widely used, and the corresponding parametric design using secondary development technology is also developing. As ready-made software systems are often designed only for most common features, such as 3D software Pro / E, which has strong graphics generation and editing ability, we can use the ready-made resources of the software as a part of the functional module of secondary development to exchange data between these different systems through interface technology, so as to realize a CAD system or CAD / CAM integrated system with relatively perfect functions. Parametric design using secondary development technology is an advanced modeling technology developed recently. It avoids the tedious manual modeling and improves the accuracy and efficiency of modeling design. It is an important part in the application field of CAD technology.

Guided by the idea of parametric design, starting from the characteristics of hypoid gear itself, in visual Under the development environment of C + + 6.0, the secondary development is carried out through Pro / Toolkit interface technology to complete the establishment of hypoid gear parameterization system, which has important practical significance and research value.