In mechanical transmission systems, spur gears are fundamental components due to their simplicity and efficiency in transmitting motion and power between parallel shafts. The design of spur gears often involves standard tooth profiles defined by international norms, such as pressure angle and addendum coefficients. However, engineering applications frequently demand non-standard tooth profiles to meet specific performance requirements, such as increased contact ratio, reduced noise, enhanced strength, or improved resistance to wear. These non-standard profiles, including those with pressure angles deviating from the standard 20° or with modified addendum heights, pose significant challenges in accurate three-dimensional modeling. Additionally, the incorporation of profile shift (or modification) in spur gears—whether for adjusting center distances or optimizing meshing characteristics—further complicates the modeling process. Traditional design methods rely on manual calculations and approximations, which can lead to inaccuracies, especially in stress concentration zones. Therefore, leveraging advanced CAD software like Pro/ENGINEER (Pro/E) for parametric modeling offers a robust solution, enabling precise, adaptable, and efficient design of non-standard tooth profile spur gears with profile shift. This article explores a comprehensive methodology for parameterized modeling of such spur gears, utilizing Pro/E’s capabilities to ensure accuracy and facilitate series production and CAE analysis.

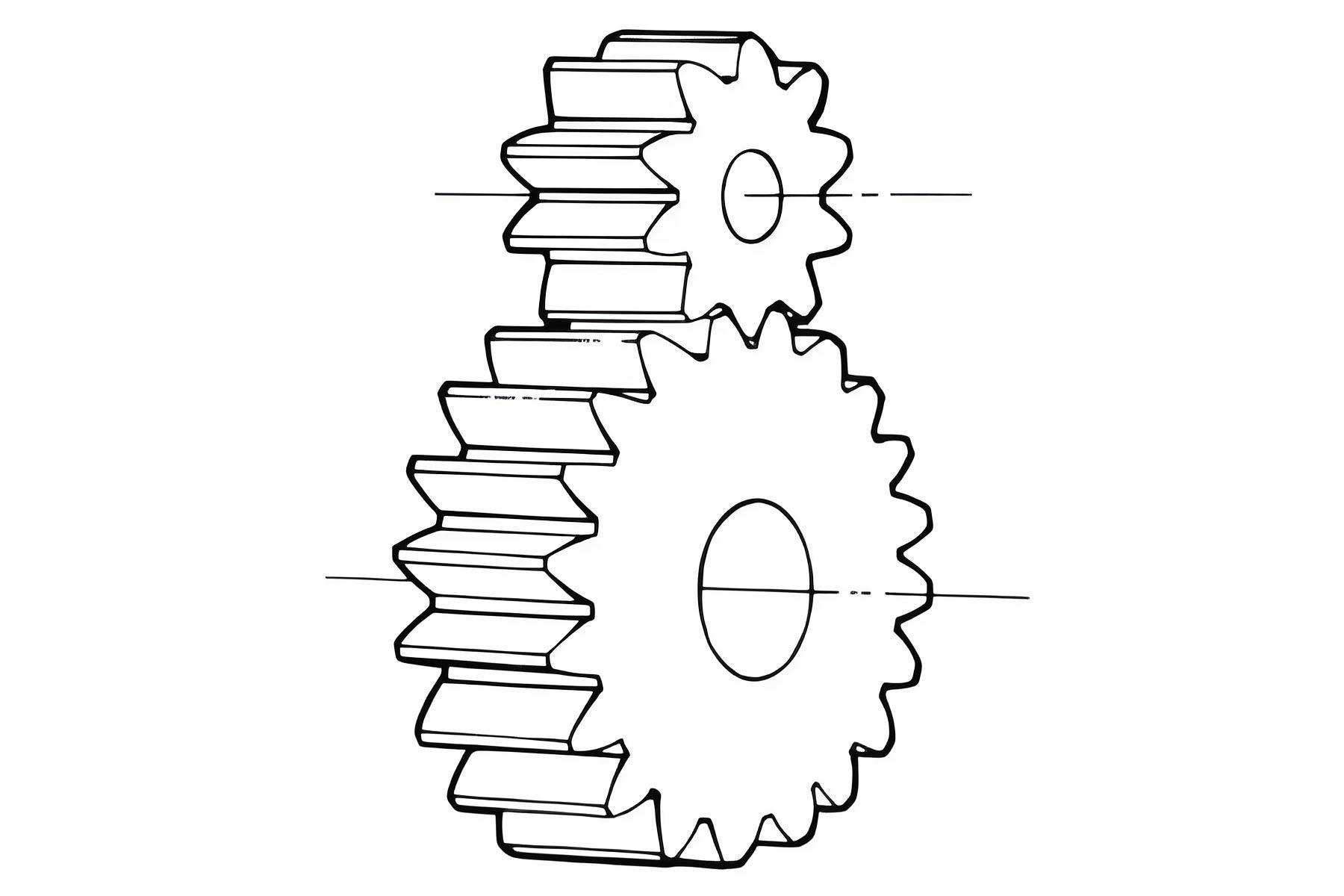

The foundation of any accurate spur gear model lies in the precise representation of the involute tooth profile. The involute curve ensures constant velocity ratio during meshing, making it critical for dynamic performance. An involute is generated when a straight line, known as the generatrix, rolls without slipping on a base circle. As shown in the figure, point K on the generatrix traces the involute curve AK. The key parameters include the base circle radius \( r_b \), the pressure angle \( \alpha_k \) at point K, and the involute function represented by the roll angle \( \theta_k \). The mathematical relationship is derived from the geometry of the generation process. The polar coordinates of the involute are given by:

$$ r_k = \frac{r_b}{\cos \alpha_k} $$

$$ \theta_k = \text{inv} \alpha_k = \tan \alpha_k – \alpha_k $$

Here, \( \text{inv} \alpha_k \) is the involute function, and \( \alpha_k \) is in radians. For practical implementation in CAD systems, it is often converted to Cartesian coordinates. Thus, the parametric equations in Pro/E can be expressed as:

$$ x = r_k \cos \theta_k $$

$$ y = r_k \sin \theta_k $$

$$ \text{with } r_k = \frac{r_b}{\cos \alpha_k} \text{ and } \theta_k = (\tan \alpha_k – \alpha_k) \cdot \frac{180}{\pi} $$

This formulation allows for the exact construction of the involute curve, which is essential for modeling both standard and non-standard spur gears. In non-standard spur gears, parameters like pressure angle \( \alpha \) may deviate from 20°, and addendum coefficients \( h_a^* \) may be less than or greater than 1, leading to short or long tooth profiles, respectively. These variations alter the tooth geometry but still rely on the same base circle-generated involute.

Profile shift in spur gears introduces another layer of complexity. Profile shift involves displacing the tool relative to the gear blank during cutting, resulting in a modified tooth thickness and root geometry. There are three primary types of profile shift in spur gears: standard gears with zero shift, high-shift gears where the sum of shift coefficients of mating gears is zero (also known as V-zero gears), and angular-shift gears where the sum is non-zero. The shift coefficient \( x \) directly affects the tooth profile: positive shift uses a portion of the involute farther from the base circle, increasing tooth thickness at the pitch circle, while negative shift uses a portion closer to the base circle, decreasing it. This influences the spur gear’s strength, wear resistance, and meshing conditions. Therefore, accurate modeling must account for these shift coefficients, along with the parameters of the mating spur gear, to ensure proper assembly and function.

To achieve a fully parameterized model of non-standard tooth profile spur gears in Pro/E, we begin by defining the input parameters. These parameters drive the entire geometry and allow for easy modifications. The essential parameters include:

| Parameter | Symbol | Description |

|---|---|---|

| Number of Teeth | \( Z \) | Tooth count of the spur gear |

| Number of Teeth (Mating Gear) | \( Z_p \) | Tooth count of the paired spur gear |

| Module | \( m \) | Metric module (or derived from diametral pitch) |

| Diametral Pitch | \( DP \) | Imperial measure; related to module: \( m = 25.4/DP \) |

| Flag for Module Input | \( FLAG \) | Binary indicator (0 for DP input, 1 for m input) |

| Pressure Angle | \( \alpha \) | Non-standard values possible (e.g., 17.5° or 22.5°) |

| Profile Shift Coefficient | \( x \) | Shift factor for the spur gear |

| Profile Shift Coefficient (Mating) | \( x_p \) | Shift factor for the paired spur gear |

| Addendum Coefficient | \( h_a^* \) | Non-standard values (e.g., 0.8 for short teeth, 1.25 for long teeth) |

| Dedendum Clearance Coefficient | \( c^* \) | Typically 0.25, but can vary |

| Face Width | \( B \) | Thickness of the spur gear along the axis |

These parameters are input into Pro/E’s parameter editor. Subsequently, relationships and programs are written to compute dependent geometric dimensions. The core calculations involve determining the pitch diameter, base diameter, addendum, dedendum, and tooth thickness. The formulas vary based on the type of profile shift. For a standard spur gear (\( x = 0, x_p = 0 \)):

$$ d = m \cdot Z $$

$$ d_b = d \cdot \cos \alpha $$

$$ h_a = m \cdot h_a^* $$

$$ h_f = m \cdot (h_a^* + c^*) $$

$$ d_a = d + 2h_a $$

$$ d_f = d – 2h_f $$

For high-shift spur gears (\( x \neq 0, x + x_p = 0 \)):

$$ d = m \cdot Z $$

$$ d_b = d \cdot \cos \alpha $$

$$ h_a = m \cdot h_a^* + m \cdot x $$

$$ h_f = m \cdot (h_a^* + c^*) – m \cdot x $$

$$ d_a = d + 2h_a $$

$$ d_f = d – 2h_f $$

For angular-shift spur gears (\( x + x_p \neq 0 \)), the calculations are more complex, involving the working pressure angle \( \alpha_w \) and center distance modification. The working pressure angle is found by solving the involute function equation:

$$ \text{inv} \alpha_w = \frac{2(x + x_p) \tan \alpha}{Z + Z_p} + \text{inv} \alpha $$

where \( \text{inv} \alpha = \tan \alpha – \alpha \). Using numerical methods in Pro/E (e.g., a SOLVE block), \( \alpha_w \) is determined. Then, the center distance increment factor \( y \) and tooth thickness modification factor \( \Delta y \) are computed:

$$ y = \frac{(Z + Z_p)(\cos \alpha / \cos \alpha_w – 1)}{2} $$

$$ \Delta y = x + x_p – y $$

The addendum and dedendum for the angular-shift spur gear become:

$$ h_a = m \cdot h_a^* + m \cdot x – m \cdot \Delta y $$

$$ h_f = m \cdot (h_a^* + c^*) – m \cdot x $$

$$ d_a = d + 2h_a $$

$$ d_f = d – 2h_f $$

These equations ensure that the spur gear model accounts for meshing conditions with its paired gear, which is crucial for assembly and performance analysis.

In Pro/E, the modeling process starts by creating a new part and defining the parameters listed above. For example, we might set \( Z = 20 \), \( Z_p = 41 \), \( DP = 12 \), \( FLAG = 0 \), \( \alpha = 17.5^\circ \), \( x = 0.455 \), \( x_p = 0.2 \), \( h_a^* = 1 \), \( c^* = 0.25 \), and \( B = 19 \). The program automatically computes the module \( m = 25.4/DP \). Relationships are then established to calculate dependent dimensions like \( d \), \( d_b \), \( d_a \), \( d_f \), and the fillet radius \( r_f \). For non-standard spur gears, the fillet radius may vary; for instance, if \( h_a^* \geq 1 \), \( r_f = 0.38m \), else \( r_f = 0.46m \). This logic is embedded in Pro/E’s relation editor using conditional statements.

Next, datum curves are sketched to represent the pitch circle, base circle, addendum circle, and dedendum circle. These circles are dimensioned using the computed parameters, ensuring full associativity. The involute curve is created via the “From Equation” option. The Cartesian equations implemented in Pro/E are:

$$ \text{Let } t \text{ range from 0 to 1} $$

$$ \alpha_k = t \cdot 45 \quad \text{(pressure angle in degrees)} $$

$$ \theta_k = (\tan(\alpha_k) – \alpha_k \cdot \pi/180) \cdot 180/\pi \quad \text{(roll angle in degrees)} $$

$$ r_k = d_b / (2 \cos(\alpha_k)) $$

$$ x = r_k \cdot \cos(\theta_k) $$

$$ y = r_k \cdot \sin(\theta_k) $$

$$ z = 0 $$

This generates an accurate involute profile based on the base circle. A datum point is created at the intersection of the involute and the pitch circle. Using this point and the gear axis, a datum plane is constructed. Another datum plane is then created by rotating this plane around the axis by an angle \( \beta \), which is calculated as:

$$ \beta = \frac{90^\circ + 360^\circ \cdot x \cdot \tan \alpha / Z}{\pi} \quad \text{(for standard and high-shift)} $$

For angular-shift spur gears, the angle incorporates the working pressure angle. This second plane serves as a mirror plane for the involute, enabling the creation of a symmetric tooth profile.

The tooth contour is sketched by connecting segments along the addendum circle, dedendum circle, and the two involute curves (original and mirrored). The root fillet is added with radius \( r_f \). This sketch is then extruded to the face width \( B \), forming a single tooth of the spur gear. The tooth is patterned circularly around the axis with the number of instances equal to \( Z \), completing the full gear model. The parameterization allows for instant updates; changing any input parameter automatically regenerates the entire spur gear geometry.

To enhance usability, Pro/E’s input parameters feature is employed. By defining an input set with prompts, designers can easily modify key values without delving into the relation editor. For instance, when regenerating the model, a menu appears asking for inputs like module, tooth count, or shift coefficient. This streamlines the design process for various spur gear configurations. Below is a summary table showcasing different spur gear models generated by varying parameters:

| Gear Type | Key Parameters | Description |

|---|---|---|

| Standard Spur Gear | \( \alpha = 20^\circ, x = 0, h_a^* = 1 \) | Conforms to standard tooth profile |

| Long Tooth Spur Gear | \( h_a^* = 1.25 \) | Increased addendum for specific applications |

| Short Tooth Spur Gear | \( h_a^* = 0.8 \) | Reduced addendum to minimize sliding |

| High-Shift Spur Gear | \( x = -0.2, x_p = 0.2 \) | Shift coefficients sum to zero |

| Angular-Shift Spur Gear | \( x = 0.455, x_p = 0.2, \alpha = 17.5^\circ \) | Non-zero sum for center distance adjustment |

The parametric modeling approach offers significant advantages for spur gear design. First, it ensures precision by using mathematical equations for the involute and geometric relationships, eliminating manual errors common in traditional drafting. Second, it saves time in product development; once the template is created, generating a new spur gear variant requires only parameter changes, making it ideal for series production. Third, the model serves as a reliable basis for CAE analysis, such as finite element analysis (FEA) for stress or thermal studies, since the geometry is exact. For example, in FEA, stress concentrations at tooth roots or contact zones can be accurately simulated, aiding in optimization. This is particularly important for non-standard spur gears, where standard formulas may not apply.

Moreover, the methodology accommodates various design scenarios. For spur gears with non-standard pressure angles, such as 17.5° for reduced noise or 22.5° for higher strength, the model adjusts automatically. The inclusion of profile shift coefficients accounts for real-world assembly requirements, ensuring that the spur gear meshes correctly with its partner. The use of Pro/E’s programmability allows for logic-based decisions, like automatically selecting the correct fillet radius or shift type based on input parameters. This intelligent automation reduces designer intervention and minimizes errors.

In conclusion, parametric modeling of non-standard tooth profile spur gears in Pro/E provides a powerful and flexible design tool. By integrating fundamental involute geometry, profile shift calculations, and parametric relationships, it enables the accurate and efficient creation of diverse spur gear configurations. This approach surpasses traditional methods in both precision and adaptability, supporting advanced engineering tasks like optimization and CAE. As mechanical systems evolve, such parameterized models will remain essential for rapid prototyping and customized spur gear production, driving innovation in transmission design.