(1) The chemical composition analysis detects whether the chemical composition of the materials selected for bevel gear meets the technical requirements of the drawing. The Q8 direct reading spectrometer is used to detect the chemical composition. See the table for the results.

| C | Si | Mn | P | S | Cr | Ni | Mo | Cu |

| 0.22 | 0.32 | 0.87 | 0.015 | 0.02 | 1.19 | 0.08 | 0.44 | 0.017 |

It can be seen from the table that the chemical composition of bevel gear material meets the requirements of Structural Steel for Ensuring Hardenability (GB/T 5216-2014).

(2) Effective case depth Effective case depth is an important technical index of carburized bevel gears. If the effective hardening layer is too shallow, the wear resistance of bevel gear is insufficient; If the effective hardened layer is too deep, the collapse and peeling speed of the hardened layer will be increased. The hardness depth and gradient of the driven bevel gear of the main reducer of the failed part were measured and calculated according to GB/T 9450-2005 Measurement and Verification of the Hardened Case Depth of Carburizing and Quenching of Steel Parts. The effective hardened case depth of 550HV1 hardness is 2.18mm, and the hardened case is slightly deeper.

(3) The grain size is compared with the standard series rating chart according to the comparison method in GB/T 6394-2017 Determination of Average Grain Size of Metals. Generally, there is a certain deviation (± 0.5 grade) when using the comparison method. The grain size of the sample in this analysis is 7.0 grade, which meets the requirements of the fine grain standard (grain size is finer than 6 grade).

(4) The metallographic sample of non-metallic inclusions shall be taken from the driven bevel gear, and the inclusion assessment shall be carried out according to GB/T 10561-2005 Determination of the Content of Non metallic Inclusions in Steel by Micrographic Examination of Standard Rating Chart. The inclusion, sulfide and homogeneity in individual field of view of the material slightly exceed the standard.

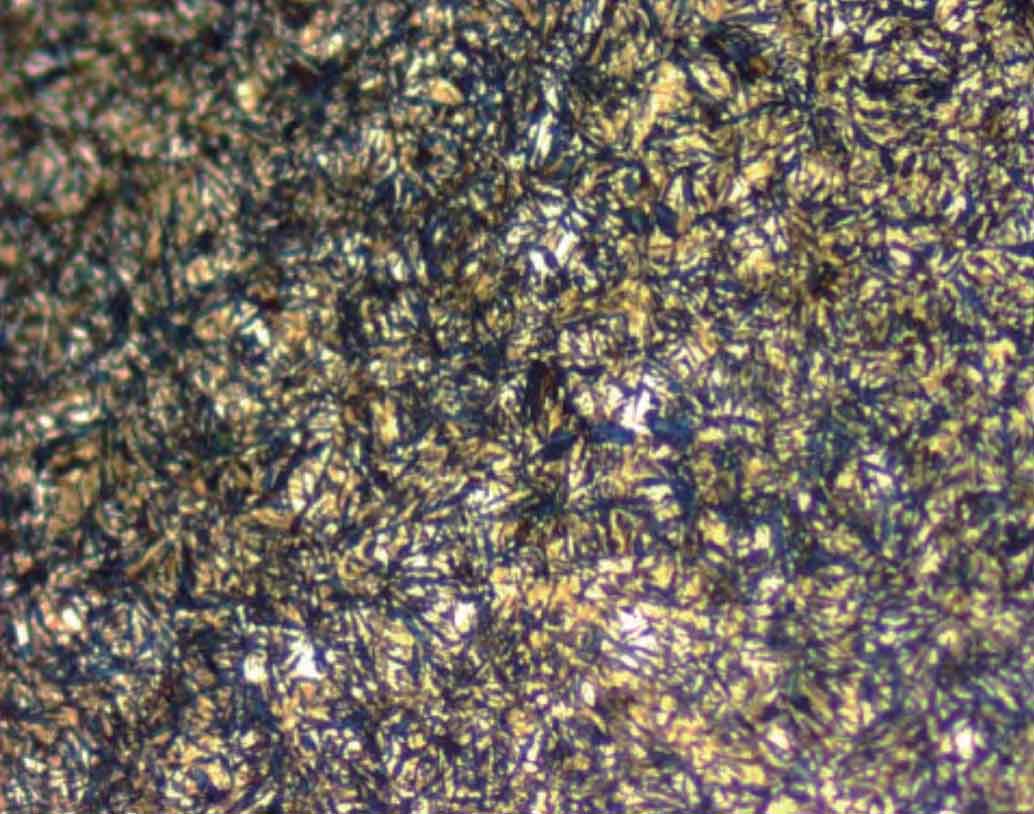

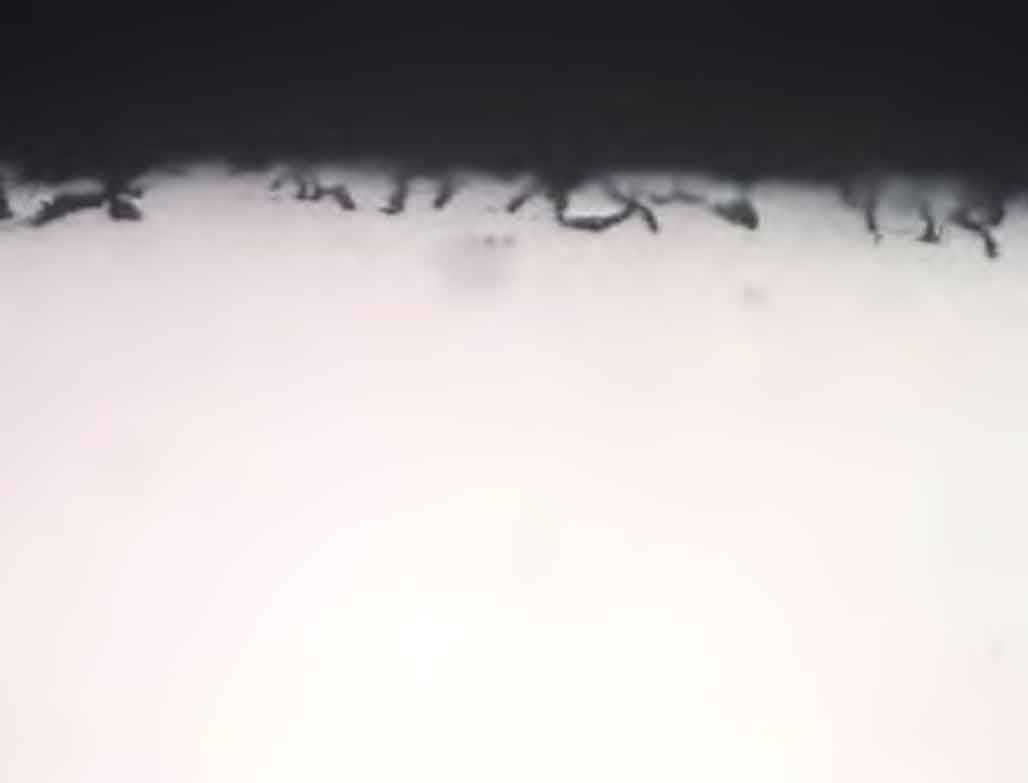

(5) The metallographic structure is taken from the driven bevel gear of the main reducer. The metallographic structure is evaluated according to the Metallographic Inspection of Automotive Carburized Gears (QC/T 262-1999). The martensite is Grade 4 (see Figure 1), the retained austenite is Grade 3 (see Figure 2), the carbide is Grade 1, and the center is Grade 3 (see Figure 3). It can be seen from Fig. 1 to Fig. 3 that martensite, retained austenite, carbide and free ferrite in the core all meet the requirements of metallographic structure. Evaluated as per GB/T 6394-2017, the grain size is Grade 7.5, acceptable. The surface hardness of 61HRC and the core hardness of 39.5HRC meet the technical requirements of the drawing. In addition, there is internal oxidation on the whole tooth surface to varying degrees. The depth of internal oxidation on the tooth surface is 0.02mm, and the maximum depth of internal oxidation (non martensitic structure) at the tooth root is 0.025mm (see Figure 4). It was found that the microcracks originated from the internal oxidation of the surface.

Internal oxidation exists on the whole bevel gear tooth surface, which is equivalent to that there are many “knife edges” on the tooth surface. Under the action of large tooth surface contact working stress, the tooth surface quickly forms microcracks at the “knife edges” of internal oxidation, and develops and extends to the interior of the brittle carburizing layer. The non martensite structure is formed due to the poor alloying element of internal oxidation. Once such structures are formed, the consequence is to reduce the surface hardness (generally referring to the hardness at ≤ 0.05mm), wear resistance and fatigue limit, and initiate fine cracks from the grain boundary or the stress concentration area of oxides and extend to deeper places.