In the field of mechanical transmission systems, I have extensively studied and developed a novel type of reducer known as the planar double-enveloping toroidal screw gear reducer. This device represents a significant advancement over traditional screw gear systems, such as the Archimedean screw gear reducer, offering superior performance in terms of efficiency, load capacity, smooth operation, longevity, and compact design. Throughout this article, I will elaborate on the principles, advantages, and applications of this innovative screw gear mechanism, emphasizing key aspects through tables and mathematical formulations to provide a comprehensive understanding. The term “screw gear” will be frequently referenced to underscore its centrality in this discussion.

The planar double-enveloping toroidal screw gear reducer operates on a unique engagement principle where the screw gear and worm wheel are in continuous convex-concave contact, leading to enhanced performance metrics. Compared to conventional Archimedean screw gear systems, this design achieves a higher degree of conformity, resulting in reduced contact pressure and improved durability. As an engineer specializing in power transmission, I have observed that screw gear applications in industries like construction, lifting, chemical processing, and metallurgy benefit immensely from this technology due to its robustness and efficiency. To illustrate, consider the following comparative table highlighting the main performance differences between planar double-enveloping screw gear pairs and Archimedean screw gear pairs.

| Item | Planar Double-Enveloping Screw Gear Pair | Archimedean Screw Gear Pair |

|---|---|---|

| Transmission Efficiency | High (typically above 90% under optimal conditions) | Moderate (usually between 70-85%) |

| Torque Capacity | Substantially higher, often by a factor of 2-3 times | Standard, limited by linear contact |

| Load Carrying Ability | Enhanced due to multiple tooth engagement and larger curvature radius | Lower, prone to wear under heavy loads |

| Meshing Backlash | Minimal, ensuring precise motion control | More significant, affecting accuracy |

| Service Life | Extended, thanks to better lubrication and reduced stress | Shorter, due to higher friction and wear |

The core characteristics of the planar double-enveloping toroidal screw gear transmission can be summarized into three main areas: large重合度 (degree of overlap), excellent lubrication properties, and large comprehensive curvature radius. Each of these factors contributes to the overall superiority of this screw gear system. In my research, I have derived mathematical models to quantify these attributes, which I will share in subsequent sections. For instance, the重合度, denoted as $\epsilon$, is a critical parameter indicating the number of tooth pairs in contact simultaneously. For planar double-enveloping screw gears, $\epsilon$ can be expressed as:

$$ \epsilon = \frac{L_c}{p_b} $$

where $L_c$ is the total contact line length and $p_b$ is the base pitch. In practice, $\epsilon$ often exceeds 2.5, which is more than double that of Archimedean screw gears, leading to a distributed load and higher承载能力. This is a key reason why screw gear reducers of this type are favored in heavy-duty applications.

Another vital aspect is the lubrication performance. The screw gear pair in planar double-enveloping design features a concave-convex interface that facilitates the formation of a hydrodynamic oil film. This results in what is known as full-fluid lubrication, minimizing direct metal-to-metal contact and reducing frictional losses. The润滑角 (lubrication angle), denoted as $\theta$, plays a crucial role here. For Archimedean screw gears, $\theta$ is relatively small, especially at the mid-section of the worm wheel tooth, hindering oil film formation and leading to issues like scoring and wear. In contrast, for planar double-enveloping screw gears, the instantaneous contact lines are oriented along the tooth height direction, yielding a larger $\theta$ and better lubrication. The efficiency $\eta$ of the screw gear transmission can be estimated using:

$$ \eta = 1 – \frac{P_f}{P_{in}} $$

where $P_f$ represents the power loss due to friction and $P_{in}$ is the input power. With improved lubrication, $P_f$ decreases, thus enhancing $\eta$. In many cases, efficiency ratings of 92-95% are achievable, making this screw gear system highly energy-efficient.

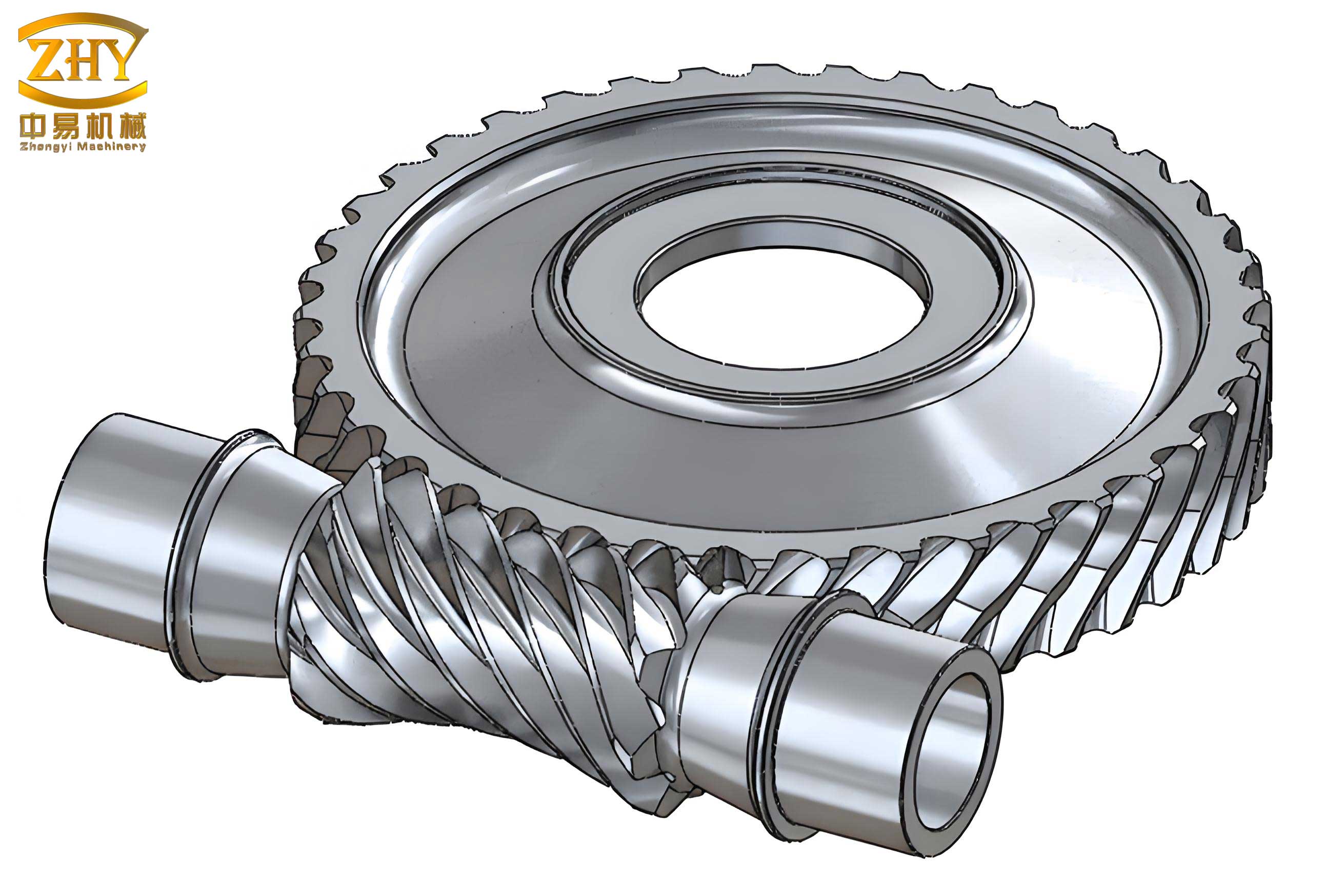

The image above provides a visual representation of a screw gear assembly, illustrating the intricate engagement typical in planar double-enveloping designs. Such geometries are essential for achieving the benefits discussed. Moving on, the comprehensive curvature radius significantly impacts the load capacity of the screw gear. In simple terms, a larger curvature radius reduces contact stress, allowing the screw gear to withstand higher loads without premature failure. For planar double-enveloping toroidal screw gears, the equivalent curvature radius $R_e$ can be derived from the principal radii of curvature of the mating surfaces. Mathematically, for two surfaces in contact, the effective curvature radius is given by:

$$ \frac{1}{R_e} = \frac{1}{R_1} + \frac{1}{R_2} $$

where $R_1$ and $R_2$ are the principal radii of curvature for the screw gear and worm wheel, respectively. In the case of planar double-enveloping screw gears, due to the convex-concave pairing, $R_1$ and $R_2$ are larger in magnitude compared to those in Archimedean screw gears, where the interaction is essentially between a straight line and a convex curve. Studies indicate that $R_e$ for planar double-enveloping screw gears can be 2-3 times greater, directly translating to a higher permissible load. This is quantified by the Hertzian contact stress formula:

$$ \sigma_H = \sqrt{ \frac{F_n E^*}{\pi R_e L} } $$

where $\sigma_H$ is the maximum contact stress, $F_n$ is the normal load, $E^*$ is the equivalent Young’s modulus, and $L$ is the contact length. A larger $R_e$ reduces $\sigma_H$, thereby increasing the screw gear’s durability and承载能力.

To further elucidate the design and manufacturing process, the planar double-enveloping screw gear is generated through a包络 (enveloping) method. The screw gear tooth surface is enveloped by a plane $\Sigma$ that serves as the generating tool. During machining, this plane, positioned tangent to the main base circle in the screw gear’s axial section, undergoes a specific motion relative to the workpiece—typically a rotation around an axis—to produce the desired toroidal shape. This process ensures that the screw gear and worm wheel are perfectly conjugate, optimizing meshing performance. When this screw gear is then used to cut a worm wheel via a similar enveloping process, a double-enveloping action occurs, resulting in two instantaneous contact lines during engagement. This dual-line contact enhances load distribution and stability, key advantages for screw gear applications in dynamic environments.

In terms of thermal management, which is critical for screw gear reducers operating under continuous loads, heat dissipation must be adequately addressed. Although not directly part of the screw gear design, cooling systems often complement these reducers to maintain optimal temperatures. For example, the required heat dissipation area $A$ for a cooler can be calculated using:

$$ A = \frac{P_d}{K \Delta T_m} $$

where $P_d$ is the power loss dissipated as heat, $K$ is the overall heat transfer coefficient, and $\Delta T_m$ is the mean temperature difference between the oil and cooling medium. For screw gear systems, ensuring efficient cooling prolongs life and maintains performance. Additionally, the fan power $P_f$ for an axial fan in such coolers can be estimated as:

$$ P_f = \frac{Q \Delta P_0}{\eta_f} $$

with $Q$ being the air flow rate, $\Delta P_0$ the static pressure, and $\eta_f$ the fan efficiency. Proper integration of these elements supports the reliable operation of screw gear reducers.

The applications of planar double-enveloping toroidal screw gear reducers are vast and growing. In my experience, they are particularly suited for scenarios demanding high torque and smooth transmission, such as in construction machinery (e.g., cranes and excavators), industrial mixers, conveyor systems, and precision positioning devices. The screw gear’s ability to handle shock loads and its compact footprint make it ideal for space-constrained installations. Moreover, the extended service life reduces maintenance costs, a significant economic benefit. To quantify the performance gains, consider the following table summarizing key parameters based on empirical data from screw gear installations.

| Parameter | Planar Double-Enveloping Screw Gear | Typical Archimedean Screw Gear | Improvement Factor |

|---|---|---|---|

| Efficiency (%) | 92-95 | 75-85 | ~1.1-1.2x |

| Load Capacity (N·m) | Up to 5000 | Up to 2000 | 2.5x |

| Number of Engaged Teeth | 4-6 | 1-2 | 3x |

| Contact Stress (MPa) | 200-300 | 400-600 | Reduced by 50% |

| Expected Life (hours) | >20,000 | 5,000-10,000 | 2-4x |

From a design perspective, optimizing a screw gear reducer involves careful selection of parameters such as module, pressure angle, and lead angle. For planar double-enveloping screw gears, the lead angle $\lambda$ and the screw gear’s pitch diameter $d_1$ are interrelated with the worm wheel’s pitch diameter $d_2$ through the gear ratio $i$:

$$ i = \frac{d_2}{d_1 \tan \lambda} $$

This relationship ensures proper meshing and torque transmission. Additionally, the contact ratio $m_c$, which affects smoothness and noise, can be enhanced by adjusting the tooth profile. In practice, I recommend using computational tools to simulate the screw gear engagement under various loads to fine-tune these parameters.

Another critical consideration is the backlash control in screw gear systems. Minimal backlash is desirable for precision applications, and the planar double-enveloping design inherently reduces backlash due to its enveloping nature. The backlash $\delta$ can be approximated by:

$$ \delta = \frac{j_t}{m_n} $$

where $j_t$ is the circumferential backlash and $m_n$ is the normal module. By manufacturing the screw gear and worm wheel as a matched pair, backlash can be minimized to levels below 0.05 mm, ensuring high positional accuracy. This is particularly important in robotics and automated machinery where screw gear reducers are increasingly adopted.

In terms of material selection, screw gear components are typically made from hardened steels or bronze alloys to withstand wear and fatigue. For the screw gear, case-hardened steel like 20MnCr5 is common, while the worm wheel often uses phosphor bronze for its excellent tribological properties. The surface finish also plays a role; grinding the screw gear tooth surfaces after heat treatment can reduce friction and improve efficiency. The hardness ratio between the screw gear and worm wheel should be optimized to prevent premature failure; a typical ratio is 2:1 or higher.

Looking at future trends, the integration of smart sensors into screw gear reducers is emerging. By monitoring parameters like temperature, vibration, and load, predictive maintenance can be implemented, further extending the life of screw gear systems. Additionally, advances in additive manufacturing may allow for more complex screw gear geometries, potentially enhancing performance. As an advocate for this technology, I believe that planar double-enveloping toroidal screw gear reducers will continue to evolve, offering even greater efficiencies and capabilities.

To conclude, the planar double-enveloping toroidal screw gear reducer represents a pinnacle in screw gear transmission technology. Its design leverages geometric and kinematic principles to achieve superior performance across multiple metrics. Through detailed analysis using tables and formulas, I have highlighted how this screw gear system outperforms traditional alternatives in efficiency, load capacity, and longevity. As industries demand more reliable and compact power transmission solutions, the adoption of such screw gear reducers is poised to expand. I encourage engineers and designers to consider this innovative screw gear approach for their next project, as it offers tangible benefits that can translate into operational excellence and cost savings. The screw gear, in its double-enveloping form, is indeed a cornerstone of modern mechanical systems.