In the evolving landscape of actuation technology, the transition from traditional hydraulic and pneumatic systems to advanced electromechanical solutions represents a significant paradigm shift. Among these, actuators based on the planetary roller screw assembly have emerged as a superior alternative for demanding applications. From my perspective as an engineer analyzing transmission systems, the fundamental advantage lies in their unique mechanical architecture. This design elegantly merges the principles of planetary gearing with a screw-nut mechanism, but replaces conventional balls with threaded rollers. This fundamental shift from point contact (as seen in ball screws) to line contact is the cornerstone of its exceptional performance characteristics.

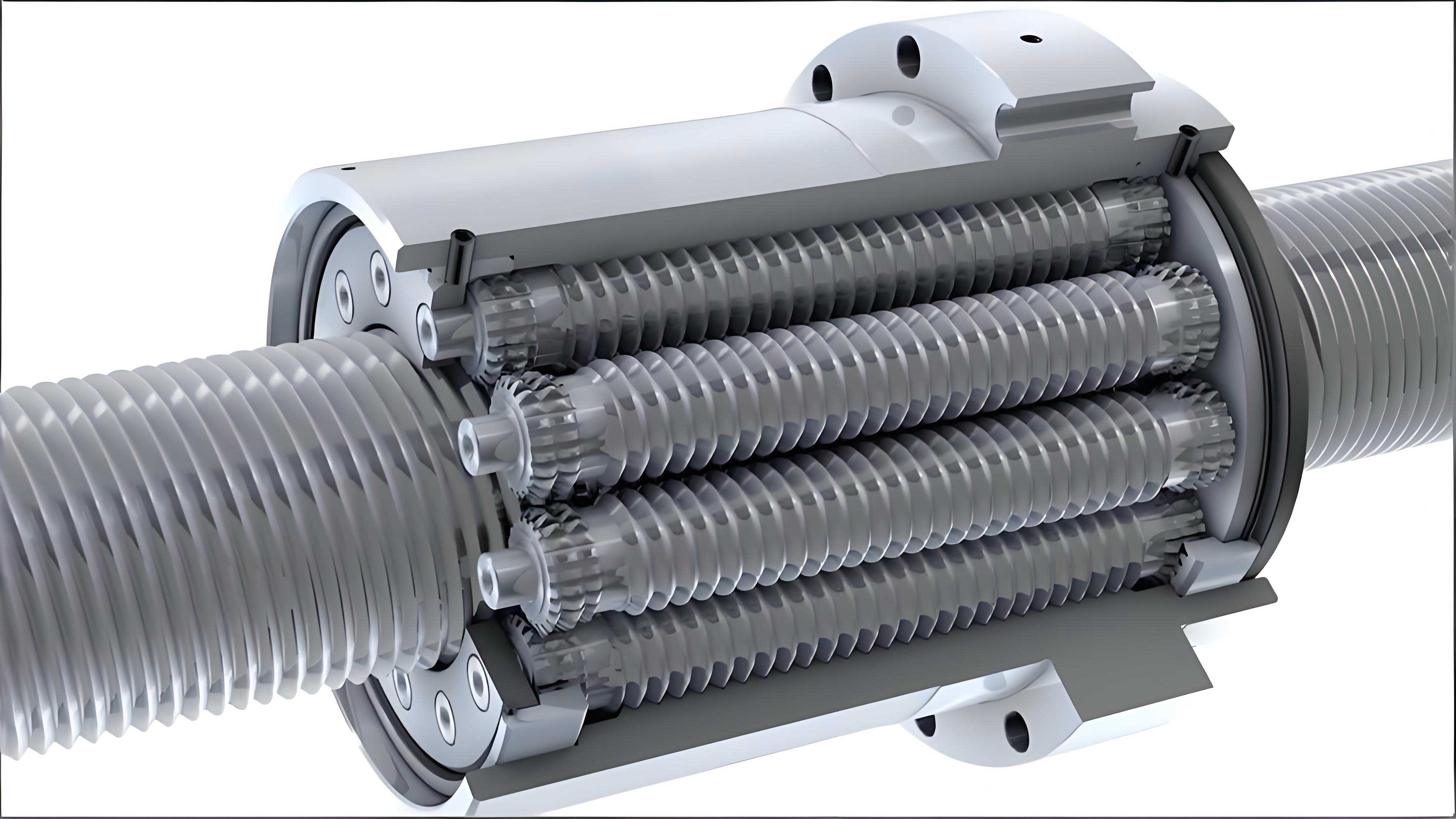

The core of a planetary roller screw assembly consists of three primary components: a central screw with a multi-start thread, a nut with a corresponding internal multi-start thread, and several threaded rollers that act as planetary elements. The rollers are evenly distributed around the screw and are meshed with both the screw and the nut. Their ends are typically geared to synchronize their orbital motion, preventing skewing and ensuring uniform load distribution. The kinematic relationship can be described by considering the lead of each component. For a standard design where the screw has $N_s$ starts with a lead $L_s$, the nut has $N_n$ starts, and each roller is a single-start thread with lead $L_r$, the transmission ratio governing the linear motion of the nut per revolution of the screw is crucial.

The linear displacement $S$ of the nut per revolution of the screw is given by:

$$ S = L_s \cdot \left(1 – \frac{N_s}{N_n}\right) $$

This equation highlights how the multi-start design of the nut and screw, combined with the planetary motion, allows for a high mechanical advantage and fine linear displacement control, which is a direct outcome of the specific geometry within the planetary roller screw assembly.

To fully appreciate the innovation of the planetary roller screw assembly, it is instructive to compare it with other common linear motion technologies. The following table summarizes the key operational differences.

| Feature | Acme/Trapezoidal Screw | Ball Screw | Planetary Roller Screw |

|---|---|---|---|

| Contact Mechanism | Sliding Friction | Point Contact (Rolling) | Line Contact (Rolling) |

| Typical Efficiency | 20% – 50% | 85% – 95% | > 90% |

| Load Capacity | Moderate | High | Very High (3-5x Ball Screw) |

| Shock Load Tolerance | Poor | Good | Excellent |

| Maximum Speed | Very Low | High | Very High (≥ 6000 RPM) |

| Life Expectancy | Short | Long | Very Long (≥ 15x Ball Screw) |

| Noise Generation | Low (at low speed) | Moderate/High (from ball circulation) | Low (high-frequency gear mesh) |

Integrating this superior transmission component with a high-performance servo motor creates the planetary roller screw electric actuator. This integration is not merely mechanical coupling; it represents a systems-level approach to motion control. The actuator’s performance is a function of the motor’s dynamic response and the exceptional mechanical properties of the planetary roller screw assembly. The fundamental dynamic equation governing the actuator’s motion is:

$$ F_a = J_t \cdot \alpha + F_{load} + F_{friction} $$

Where $F_a$ is the force generated by the planetary roller screw assembly, $J_t$ is the total inertia reflected to the screw, $\alpha$ is the angular acceleration, $F_{load}$ is the external force, and $F_{friction}$ is the system’s friction. The low inertia and high stiffness of the planetary roller screw assembly contribute directly to a high $\alpha$, enabling exceptional acceleration and dynamic response.

The defining advantages of actuators built around a planetary roller screw assembly are multifaceted and stem directly from its mechanical design:

- Extreme Load and Durability: The line contact and multiple load-bearing threads distribute force across a vastly larger surface area than ball screws. This not only increases static load capacity but dramatically enhances fatigue life. The dynamic load rating $C$ for a planetary roller screw assembly follows a modified Lundberg-Palmgren bearing theory, resulting in a life calculation $L_{10}$ (revolutions in millions at 90% reliability) that is significantly higher:

$$ L_{10} = \left( \frac{C}{F_{eq}} \right)^3 $$

where $F_{eq}$ is the equivalent dynamic load. The exponent of 3 is standard for roller bearings, but the magnitude of $C$ is substantially greater for an equivalent envelope size compared to a ball screw. - High Speed and Acceleration: The absence of ball recirculation components eliminates a major source of inertial loss and impact noise at high speeds. The limiting factor becomes the centrifugal forces on the rollers and the first critical speed of the screw shaft. Advanced designs with hollow screws and optimized roller profiles can achieve linear speeds exceeding 2 m/s and accelerations over 3 g.

- Compactness and Stiffness: The high load density means a planetary roller screw assembly can deliver the same force as a ball screw in a roughly one-third smaller package. Furthermore, the line contact and preload capability yield a very high axial stiffness $k_{ax}$, which is critical for precise positioning and dynamic stability:

$$ k_{ax} = \frac{dF}{dx} \approx \frac{n \cdot k_c \cdot \cos^2(\beta)}{1} $$

where $n$ is the number of loaded rollers, $k_c$ is the contact stiffness per roller thread, and $\beta$ is the thread helix angle. - Reliability in Harsh Environments: The robust design is less susceptible to contamination than ball screws. Sealed units can operate reliably in environments with dust, moisture, and temperature extremes where hydraulic systems would suffer from fluid leaks or viscosity changes and ball screws might jam.

The application landscape for planetary roller screw actuators is extensive and growing, driven by their unmatched performance in critical areas. In aerospace and defense, they are the cornerstone of flight control surface actuation, landing gear retraction systems (replacing hydraulics in next-generation aircraft), missile fin control, and gun turret drives. Their high force-to-weight ratio, reliability, and “power-by-wire” capability are essential here. In industrial automation, they dominate high-duty-cycle applications like metal forming presses, injection molding machines, and heavy-duty robotic welding where high force, precision, and millions of cycles are required. The test and simulation sector relies on them for high-frequency shake tables, fatigue testing systems, and advanced motion platforms due to their dynamic response and load capacity. Even in energy, they control large valve actuators in oil & gas and provide precise positioning in nuclear facilities.

The global development status of this technology is asymmetric. Pioneering work in the design and manufacturing of precision planetary roller screw assembly components has been concentrated with specialized firms in Europe and North America for decades. These entities have mastered the intricate processes of thread grinding, heat treatment for hardened alloys like AISI 52100 or M50 steel, precision gear cutting on roller ends, and assembly under controlled conditions to achieve the necessary preload and alignment. The actuator integration, particularly the trend toward direct-drive designs where the motor rotor is mounted directly on the screw, further pushes the boundaries of power density and dynamic performance. In contrast, the development cycle in other regions has started more recently, focusing initially on understanding the fundamental kinematics, load distribution, and manufacturing techniques required to produce a reliable planetary roller screw assembly. Progress is being made in material science, precision machining, and system integration, aiming to close the technological gap.

The future trajectory of planetary roller screw actuator technology is focused on overcoming current limitations and enhancing integration. The push for longer stroke lengths involves overcoming challenges like screw whipping (bending critical speed), which can be mitigated by using intermediate supports or innovative nut designs. The demand for higher payloads drives research into new materials like high-strength maraging steels or ceramic hybrids, and advanced thread profiles that optimize stress distribution. The quest for faster speeds involves analyzing and mitigating the effects of roller centrifugal forces and gyroscopic moments, often through dynamic modeling and composite material use.

Furthermore, the trend toward deep mechatronic integration is paramount. The next-generation actuator is not just a motor coupled to a planetary roller screw assembly; it is a smart subsystem. This includes embedding sensors for force, position, and temperature directly into the nut or housing, integrating the drive electronics, and implementing condition-based monitoring algorithms. The positional accuracy $\Delta x$ of such a system is a function of not just the lead accuracy $\Delta L$ of the screw, but also thermal growth $\alpha \Delta T \cdot L$ and control resolution:

$$ \Delta x = \sqrt{(\Delta L)^2 + (\alpha \Delta T \cdot L)^2 + (\frac{\text{Encoder Resolution}}{Gear Ratio})^2} $$

Advanced thermal management and direct high-resolution feedback are key to minimizing this error.

To summarize the performance envelope and advantages discussed, the following table provides a consolidated view of why the planetary roller screw assembly is transformative.

| Performance Parameter | Typical Advantage Over Ball Screws | Primary Reason (Rooted in Design) |

|---|---|---|

| Static Load Capacity | 3x to 5x higher | Line contact vs. point contact; More load-bearing threads engaged. |

| Dynamic Load Rating & Life (L10) | 10x to 15x longer life | Superior stress distribution and larger contact area reduce subsurface shear stresses. |

| Axial Stiffness | 2x to 3x stiffer | Line contact provides greater resistance to elastic deformation under load. |

| Shock Load Tolerance | Exceptionally higher | Robust mechanical design with no delicate recirculation components; higher inherent strength. |

| Maximum Operational Speed | 20% to 50% higher | Elimination of ball circulation limits; smoother kinematic chain. |

| Acceleration Capability | Significantly higher | Lower reflected inertia due to design and potential for hollow screw. |

| Environmental Robustness | Greatly improved | Less sensitive to particulate contamination; can be sealed more effectively. |

In conclusion, the actuator systems centered on the planetary roller screw assembly represent a pinnacle of electromechanical transmission design. Their superiority in load, speed, life, and reliability is not incidental but is fundamentally engineered into their architecture through the principle of multi-roller planetary line contact. As the global industry moves towards more electric, efficient, and high-performance systems, the role of these actuators will only expand. The ongoing research into advanced materials, integrated smart features, and refined manufacturing processes for the core planetary roller screw assembly will continue to push the boundaries, enabling new applications in robotics, advanced manufacturing, aerospace, and beyond, solidifying their status as the optimal solution for the most demanding linear motion challenges.