Abstract

To enhance the machining accuracy of orthogonal spur face gear, this study presents a precise design method for the skiving tools employed in their manufacturing. Based on the meshing principle of gears with crossed axes, the skiving process of spur face gear is meticulously analyzed. The tooth profile of a mating cylindrical gear is enveloped to derive the tooth surface equation of the skiving tool. Subsequently, the tool structure is designed with no error, and the cutting edge expression is derived on the normal plane. By solving the meshing conditions between the cutting edge and spur face gear, numerical control machining laws are deduced, and theoretical calculations and simulation processing of spur face gear tooth surface are performed. Numerical comparisons between the skived tooth surface and the theoretical tooth surface indicate that the theoretical tooth surface of spur face gear can be achieved when the skiving tool is error-free. Furthermore, in Vericut simulations, the tooth surface error remains within 10 µm.

1. Introduction

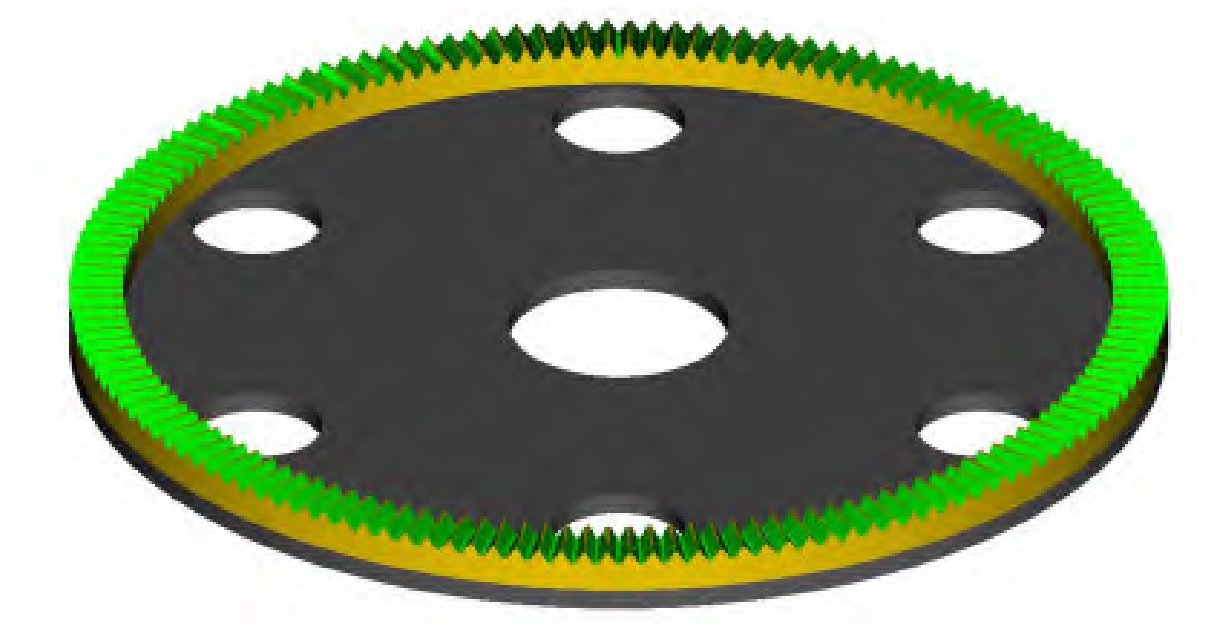

Face gear transmissions, which consist of spur face gear mating with cylindrical gear, exhibit several advantages such as high contact ratio, compact size, light weight, and substantial torque transmission capabilities. These transmissions find extensive applications in automotive and aerospace industries (Litvin and Fuentes, 2004). Traditional manufacturing methods for face gears, including hobbing and shaping, have their limitations. For instance, shaping involves idle strokes, reducing efficiency, while hobbing tools are complex and costly due to their intricate structures (Zhang et al., 2021).

Skiving, also known as skimming or power skiving, offers an attractive alternative. It combines the advantages of both shaping and hobbing, achieving higher processing efficiency than shaping (approximately 4-4.2 times) and comparable accuracy (grade 7) (Guo et al., 2022). Additionally, skiving tools are less complex than hobbing tools, enabling cost savings by utilizing existing machine tools. However, skiving introduces inherent errors that limit processing precision, especially for orthogonal spur face gear. This study aims to eliminate these errors through a precise design methodology for skiving tools.

2. Literature Review

Previous studies have contributed significantly to the development of skiving techniques. Mao (2014) analyzed the cutting edge curve of skiving tools and highlighted their relative motion with the gear being machined. Jia et al. (2019) established a mathematical model for skiving simulation based on discrete curve enveloping. Han et al. (2022) proposed a skiving tool with rounded corners to achieve controllable transmission errors when mating with cylindrical gear. Guo et al. (2019) designed a multi-blade conical skiving tool to enhance efficiency while maintaining precision. Chen et al. (2022) studied the evolution of tool working angles during the skiving process, emphasizing the importance of spiral angle and feed rate. Mo et al. (2022) reduced inherent errors by modifying the skiving tool based on a rack cutter.

3. Skiving Process Principles

The skiving process can be conceptualized as a meshing motion between a pair of gears with crossed axes. By forcing the skiving tool and face gear blank into meshing, excess material is removed to achieve the desired tooth profile. Figure 1 illustrates the skiving process, where various velocity components contribute to the cutting speed.

The angular velocity relationship between the tool and gear is governed by their respective rotational speeds and the axis crossing angle (ε), which depends on the tool and gear spiral angles (βv and β2, respectively). The cutting speed (v) is determined by the resultant of the gear linear velocity (vg) and the tangential tool velocity (vvt), adjusted by the velocity components along the gear helix (vva) and feed direction (v01).

4. Tool Design Methodology

This section outlines the precise design methodology for skiving tools, focusing on orthogonal spur face gears.

4.1 Enveloping the Tool Tooth Surface

The tooth profile of the mating cylindrical gear (pinion) is enveloped to form the skiving tool tooth surface. Figure 2 depicts the positional relationship between the face gear, pinion, and skiving tool.

The pinion tooth surface equation (R1) in the S1 coordinate system is expressed as:

R_1(u_1, \theta_1) = \left[ \begin{array}{c} r_{b1} \left[ \cos(\theta_1 + \theta_{o1}) + \theta_1 \sin(\theta_1 + \theta_{o1}) \right] \\ r_{b1} \left[ \sin(\theta_1 + \theta_{o1}) – \theta_1 \cos(\theta_1 + \theta_{o1}) \right] \\ u_1 end{array} \right]

where rb1 is the base circle radius of the pinion, z1 is the pinion tooth count, α is the pressure angle at the pitch circle, θ1 is the involute angle parameter, θo1 is the base circle tooth space angle, and u1 is the tooth width parameter.

4.2 Derivation of the Cutting Edge

To impart cutting capabilities, the tool tooth surface is modified to include a rake angle (η) and clearance angle (Δβ). A normal plane perpendicular to the tool tooth surface is rotated by η to obtain an auxiliary plane, which intersects the tooth surface to form the cutting edge.

The cutting edge equation (Rc) is derived by solving the intersection of the rotated auxiliary plane and the tool tooth surface, resulting in:

Rc=MV1R1andRc(2)tan(η)[Rc(1)sin(βv)−Rc(3)cos(βv)]=0

where Mv1 is the coordinate transformation matrix.

5. Face Gear Tooth Surface Equation

Using the precise cutting edge derived from the previous section, the face gear tooth surface is theoretically calculated.

5.1 Simulating the Pinion Tooth Profile

The cutting edge is used to generate the pinion tooth profile. A numerical comparison with the standard pinion tooth profile validates the accuracy of the cutting edge design, with a maximum error of 2.2 µm.

5.2 Face Gear Skiving Coordinates and Meshing Equations

During face gear skiving, the cutting edge simulates the pinion’s motion while engaging with the face gear along its helix, forming the entire tooth surface. The meshing equations relating the cutting edge and face gear are derived, enabling the calculation of the face gear tooth surface equation (R2).

6. Simulation and Verification

To validate the proposed tool design methodology, simulations are conducted using Vericut software, and the results are compared with theoretical tooth surfaces.

6.1 Theoretical Modeling and Comparison

Theoretical face gear tooth surfaces are modeled using the derived equations, and a comparison with the standard face gear tooth surface confirms the absence of errors.

6.2 Vericut Simulations

Vericut simulations are performed using four different tool rake angles (0°, 5°, 10°, and 15°). The resulting tooth surfaces are compared with theoretical surfaces, demonstrating errors within 10 µm (Figure 6).

Figure 6: Vericut simulation results for different tool rake angles.

7. Conclusion

This study presents a precise design methodology for skiving tools used in the manufacture of orthogonal spur face gears. By enveloping the tooth profile of the mating pinion, the tool tooth surface and cutting edge are derived. Theoretical and simulation results validate the accuracy of the proposed methodology, with errors remaining within 10 µm. This work provides a foundation for achieving high-precision manufacturing through skiving processes.