Under the condition of the same batch of spiral bevel and spiral bevel gears with the same spiral bevel gear material, NC milling method and heat treatment specification, in order to accurately find the rule and change situation of tooth surface deviation deformation after heat treatment, it is necessary to analyze the tooth surface deviation data with mathematical statistics method to obtain the parameter information about the tooth surface deviation data. The tooth surface deviation data is the relative value of the measured point on the tooth surface relative to the center point of the tooth surface. At present, the single error measurement methods of spiral bevel gears are divided into dot matrix measurement and scanning measurement. The instruments used in both methods are CNC gear measurement centers. For the advantages and disadvantages of the two methods, please refer to the scheme comparison made by Xu et al.

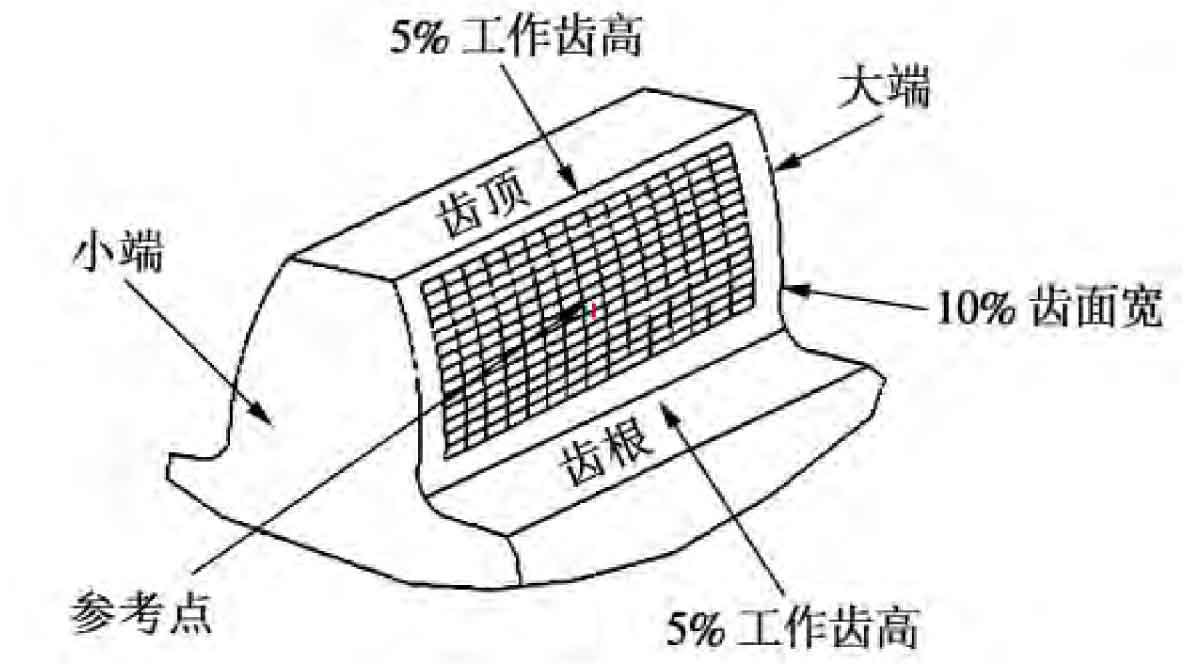

The point array measurement method is selected for measurement. The tooth surface error measurement of spiral bevel gears is based on a set of strictly defined grid points on the tooth surface. For dot matrix measurement, the grid division principle is generally based on (n × m) (where n and m are odd numbers). In order to obtain more effective and accurate data, 15 × 15 Mesh generation form of tooth surface. The regional planning is shown in Figure 1.

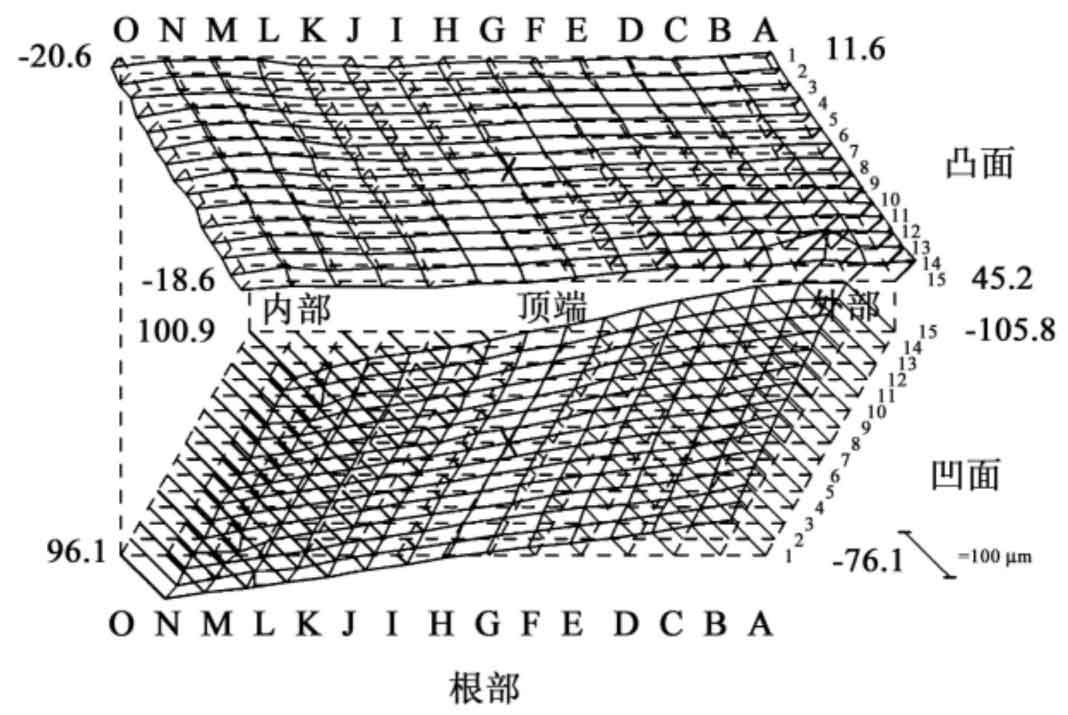

For spiral bevel gears milled by CNC gear milling method and heat treated in the same batch, 5 pairs, 10 pairs and 20 pairs of large gears and small gears were tested for tooth surface error in batches on Klingelnberg P65 gear tester. Taking the big wheel as an example, the detection process and results are shown in Figure 2 and Figure 3 respectively.