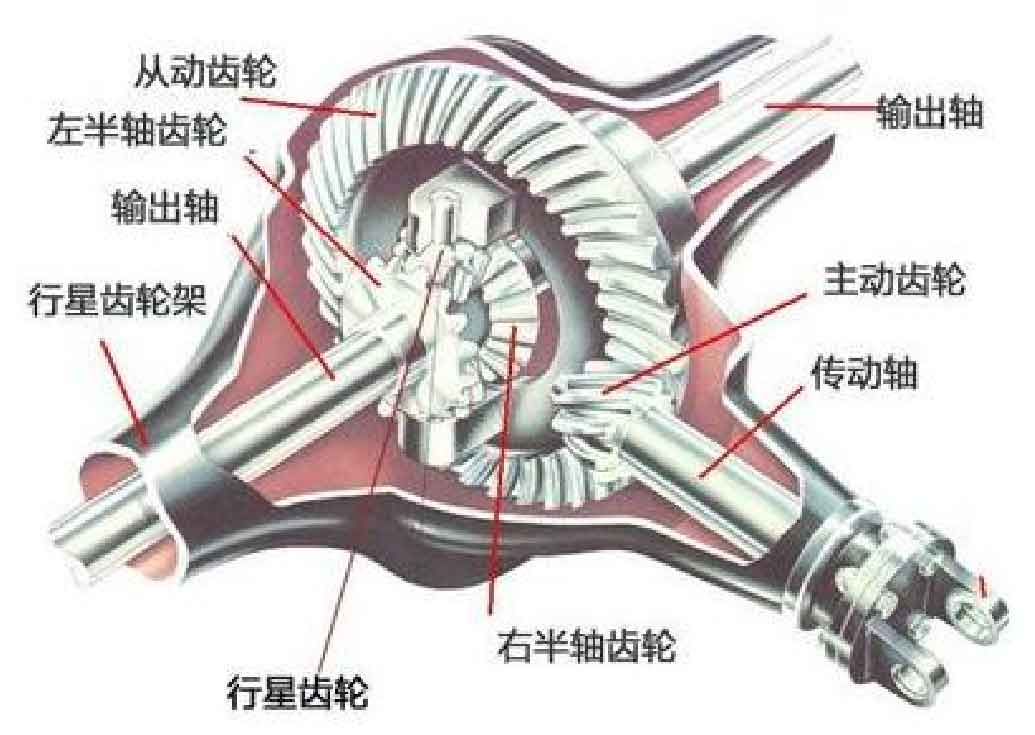

Spiral bevel gear is the most critical part of the transmission system. The service life and vehicle performance of automobile and other equipment are directly affected by the quality of spiral bevel gear. The working strength and service life of spiral bevel gear are related to its forming method and related equipment. At the same time, as the previous product of forming spiral bevel gear, some defects in its forming will play a decisive role in the quality of the finished spiral bevel gear. In the forming process of spiral bevel gear blank, if the die structure and production process conditions are unscientific, it is very easy to fold and underfill in the die forging of spiral bevel gear blank. These defects are fatal to the spiral bevel gear blank, which makes it directly become waste. Therefore, the research on gears and gear blanks has never been interrupted for many years. This paper mainly studies the preform production technology of driving spiral bevel gear, which is one of the core components of automobile rear axle transmission system. As the driving axle of the automobile, the rear axle of the automobile plays an important role in the transmission system of the automobile. Therefore, the working condition of the driving spiral bevel gear is more complex and is a consumable part in the automobile. Figure 1 is a simple schematic diagram of automobile drive axle.

In China, Wang Nan, Zhang Qingheng and others used ANSYS / LS-DYNA finite element simulation to analyze the distribution of strain field on cross section and longitudinal section, the location of maximum value and the distribution of strain value around the maximum value point through cloud diagram. The surface deformation characteristics of shaft parts rolled by cross wedge rolling are also analyzed, and the relevant data of stress, strain and axial displacement are obtained. It provides a basis for the widening angle, forming angle and material selection of cross wedge rolling die design. Academician Hu Zhenghuan of China has deep attainments in cross wedge rolling. He is the core leader in the innovation of cross wedge rolling technology from scratch to substantial improvement of technology. He has participated in and led a series of major national scientific and technological research projects related to cross wedge rolling technology and achieved a series of remarkable achievements. After years of practical production in the factory, the author has gradually explored a new production process for forging the driving spiral bevel gear blank of automobile rear axle. It is pointed out that the traditional production process consists of five processes: heating → rolling extrusion → top forging → final forging → trimming.

Because the cross-section of bevel driving gear blank changes greatly, it is necessary to consider not only the aggregate of cone head, but also the filling of cone rod tail during forging. The waste of materials in this process is serious. At the same time, in the roll extrusion process, because the accuracy of the groove is difficult to ensure, the metal flow during roll extrusion is very unreasonable. The author improved the process as follows: heating → vertical pre forging → horizontal final forging → trimming, four processes. The roll extrusion process with unstable production process and easy defects is removed, and the blank is heated to remove the oxide skin and directly enter the vertical pre forging process. The new process reduces the folding defects of the connecting part between the cone head and the rod. Through the practice verification of the author, the process improves the material utilization rate from 79% to 88.5%, and the product qualification rate is greatly improved. The repair rate also decreased from 5% ~ 6% to 2%.

The heat treatment process of automotive gear blank after forging is studied and analyzed. Starting from the cutting performance of gear blank after forging, this paper focuses on the different structures obtained by different normalizing and tempering parameters during heat treatment after forging. Firstly, through the combination of a large number of theoretical analysis and practical experience, the author believes that in order to achieve better cutting performance after heat treatment, it is necessary to obtain soft (low hardness, low strength) brittle (low plasticity) structure. This structure can be obtained by isothermal normalizing after forging the spiral bevel gear blank. Isothermal normalizing is a phase transformation of ferrite + pearlite or pearlite at constant temperature. The phase transformation is complete and has good uniformity in the whole blank. Therefore, isothermal normalizing can effectively reduce the residual stress and quenching deformation. At the same time, it can improve the cutting performance and carburizing quenching structure of spiral bevel gear blank.

The closed extrusion forming of driving spiral bevel gear is analyzed from two aspects: lead block experiment and finite element numerical simulation. The author uses lead preform to form on a pre designed die. It is found that the metal begins to fill the cavity from the small end and gradually extends to the large end. By analyzing the deformation of the mesh, it is found that the metal first compresses axially and then extends radially in the process of filling the cavity. At the end of forming, on the cross sections with a distance of 30mm, 15mm and 0mm from the large end face, the part of the grid from the center to the outer ring teeth gradually changes from circle to plum blossom shape, and the grid line of the outermost ring is almost the same as the tooth shape. Then, the closed extrusion of driving spiral bevel gear of automobile rear axle is simulated and analyzed by DEFORM-3D software. The comparison between the simulation results and the experimental results shows that the process of metal filling the tooth cavity in the forming process is the same, which is first filled from the small end and then gradually extended to the large end. Including the change of mesh in the forming process, it is also basically the same. The extrusion load stroke curves of the experimental and simulated processes are also compared. It is found that the two curves basically coincide in the deformation stability stage, and the difference is less than 15%, which is relatively reliable. In the initial stage and the final filling stage, the simulation results are quite different from the experiment. It may be due to the complex deformation in these two time periods and the difficulty of accurate simulation calculation.

Through the overall comparison between finite element simulation analysis and experiment, the author concludes that the results obtained by using finite element simulation to analyze the metal flow and the stress and strain of each part in the forming process are relatively reliable.

This paper mainly introduces the process of producing driving spiral bevel gear blank in China in the past and at present. The forming process, forming temperature and material utilization of each process are briefly introduced. It is pointed out that the production processes of driving spiral bevel gear blank include hot die forging process and warm forging process already used in China, as well as cross wedge rolling process and cross wedge rolling top pier forming process developed and gradually popularized in recent years. Through the analysis of the actual production situation of each process, the author points out that cross wedge rolling process and cross wedge rolling top pier forming process have better advantages, high material utilization rate and high production efficiency. Figure 1.2 shows the driving spiral bevel gear blank of a certain type of automobile rear axle produced by a domestic factory.