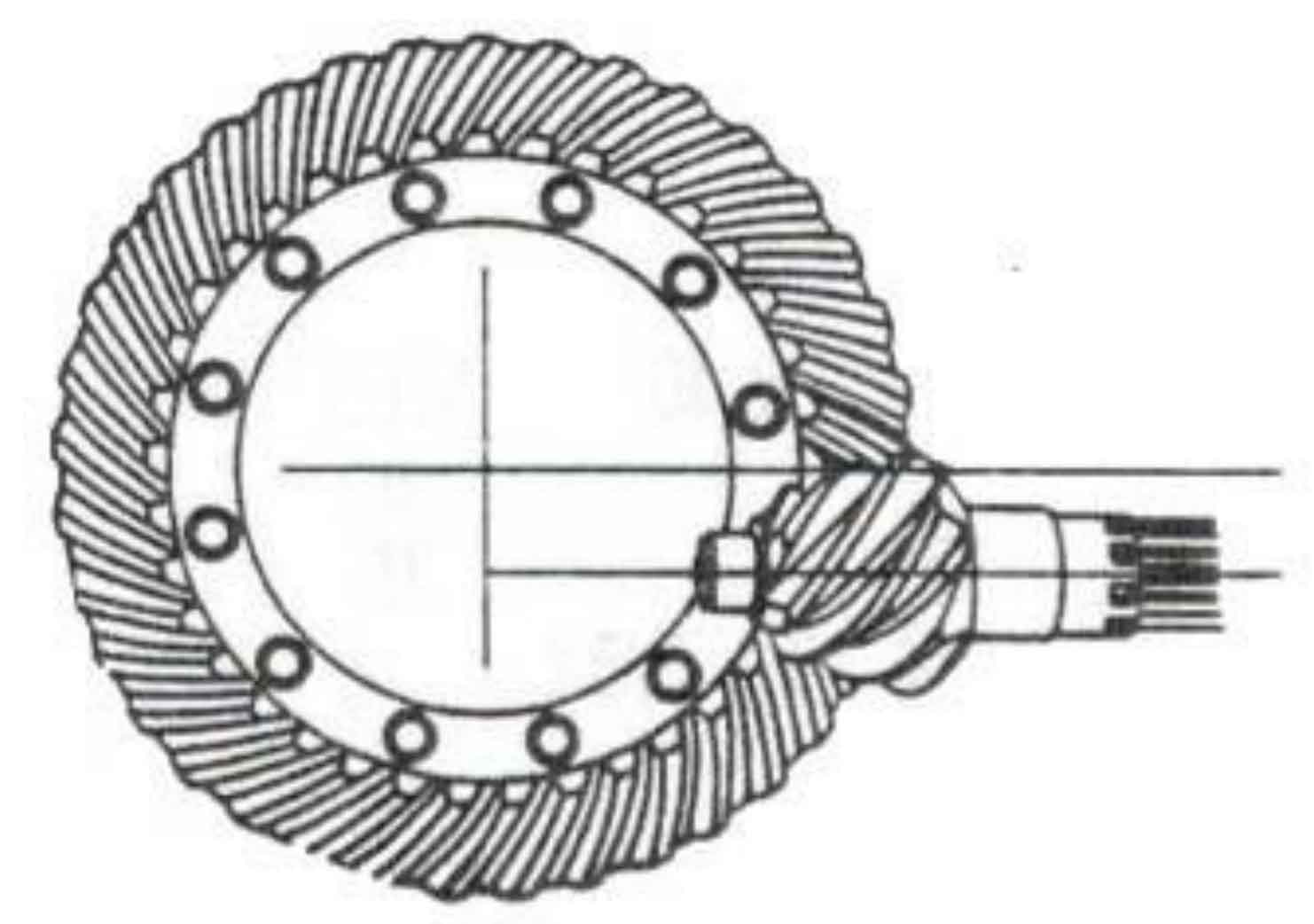

As a key assembly component in the automobile transmission system, the drive axle plays a role in reducing speed and increasing torque, changing the direction of power transmission, ensuring the turning and straight driving of the vehicle. However, because the hypoid gear of the drive axle works under the condition of high speed and high torque, it is easy to cause fatigue damage and generate large radiation noise.

This paper analyzes the machining process of the drive axle quasi double curved surface, derives the meshing equation of the hypoid gear, and establishes the tooth surface point constraint equation according to the tooth blank parameters. In view of the difficulty in solving the nonlinear equations established above, this paper analyzes the relationship between the tooth blank shape and the machining machine tool in detail, extracts the value range of the tooth surface point parameters, and uses the simulated annealing algorithm in MATLAB to obtain the parameter estimation of the tooth surface meshing midpoint, and uses the estimated value as the initial point for solving the nonlinear equations to successfully obtain the accurate parameters of the tooth surface meshing midpoint. Finally, the HFT program surface for solving the surface points of hypoid gears is established. The results show that the established tooth surface solution program can accurately and quickly obtain the tooth surface point coordinates. The tooth surface point solution method established in this paper can automatically and accurately calculate the tooth surface point coordinates, and can be applied to the establishment of similar hypoid gear geometric model.