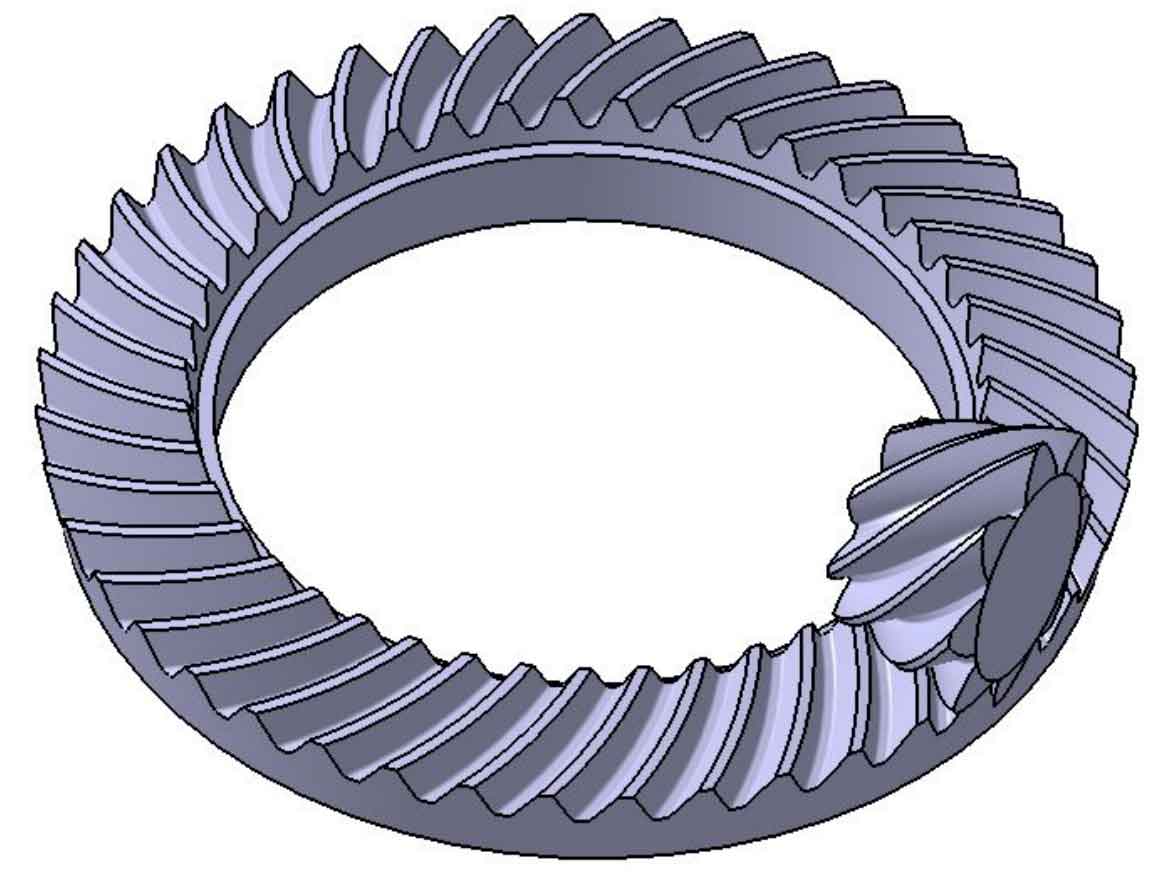

The finite element method is an important method to predict the bending stress of the hypoid gear tooth root of the automobile drive axle. However, it is difficult to determine the constraint conditions of the single hypoid gear finite element model. Therefore, a finite element analysis model for the bending stress of the hypoid gear tooth root based on the overall drive model is established in this paper. ABAQUS / standard is selected to carry out static meshing analysis of hypoid gear of drive axle. The results show that in the meshing process of the hypoid gear of the drive axle studied, the bending stress of the pinion root appears at the maximum near the big end, and the tooth root is subjected to the compressive stress first, and then the tensile stress. The bending stress of the pinion root appears at the maximum near the small end, and the tooth root is subjected to the tensile stress first, and then the compressive stress. Finally, the static and torsional test-bed of the drive axle is built, and the bending stress of the gear root of the drive axle is measured. The results of the bench test and the simulation are compared and analyzed. The results show that the established finite element model is accurate and reliable, and this modeling method can be used to analyze the bending stress of the gear root.

Based on the change history of bending stress of hypoid gear tooth root, a method of using stress-life (S-N) to quickly predict gear fatigue life is established. According to the test standard of Drive Axle Fatigue Bench enterprise, a fatigue bench test is carried out on a drive axle. The comparison between the test and prediction results shows that this method can accurately predict gear bending fatigue life. It can be used to check the bending stress and fatigue of the gear root of the drive axle.

The installation deviation of the hypoid gear of the drive axle will affect the contact state of the gear, and then the bending stress distribution state of the gear root. This chapter analyzes the influence of four typical installation deviations on the bending stress of the hypoid gear root and the fatigue life of the gear based on the finite element method, and obtains the sensitivity of the bending stress and fatigue life of the gear root to the installation deviation. It can be seen that first, the gear installation cross angle deviation has the greatest impact on the gear root stress distribution and fatigue strength, second, the installation offset distance deviation, then the pinion axial installation deviation, and finally the large gear axial installation deviation. The installation deviation of the pinion gear pair is more sensitive than that of the large gear. Reasonable adjustment of the axial installation deviation of the large gear can improve the contact state of the gear without affecting the fatigue life of the gear. These conclusions can provide guidance for fatigue life design of drive axle gears.