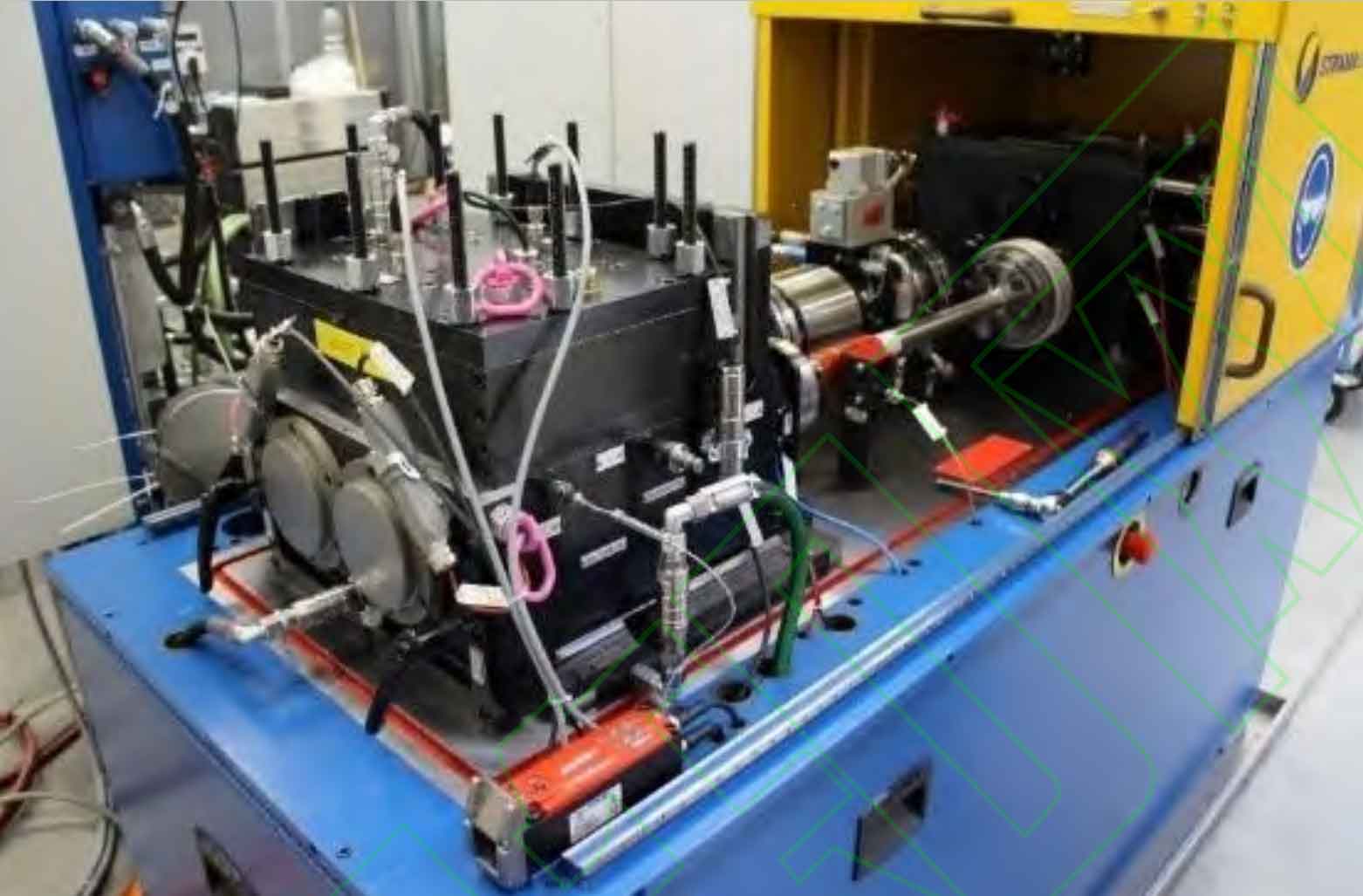

In order to verify the fatigue pitting corrosion model of cylindrical gear, the FZG cylindrical gear wear tester in the Key Laboratory of mechanical transmission of Chongqing University is used for testing, as shown in the figure below. The equipment is based on din51354, GB / T 14230-93, Nb / SH / T 0306-2013, GB / T 13672-92, SH / T 0200-92 and other standards. The test method is based on GB / T 14229-93 cylindrical gear contact fatigue strength test method. The specific test steps are as follows:

- Carry out the performance verification of the cylindrical gear testing machine according to the standard requirements, and conduct visual inspection after cleaning the test cylindrical gear. The tooth surface of the cylindrical gear shall be free of corrosion, rust or other forms of damage. Load it to the test load and check the tooth surface contact of the cylindrical gear;

- Determine the tooth surface inspection time interval according to the contact stress of the test cylindrical gear. At the beginning of the test, observe the tooth surface with a 10x magnifying glass. After finding the pitting damage of the cylindrical gear tooth surface, shorten the inspection time interval according to the damage morphology and expansion trend in time, so as to accurately record the cycle times when the limit of pitting damage of the cylindrical gear tooth surface is reached;

- If the pitting area rate has exceeded the pitting damage limit when inspecting the cylindrical gear tooth surface, take half of the time interval as the time when the interval reaches the failure of the cylindrical gear tooth surface;

- Track and inspect the morphology of pitting damage, the position on the cylindrical gear tooth surface, the tooth number and stress cycle times of the cylindrical gear tooth surface, describe and record it, and film or take photos if necessary.