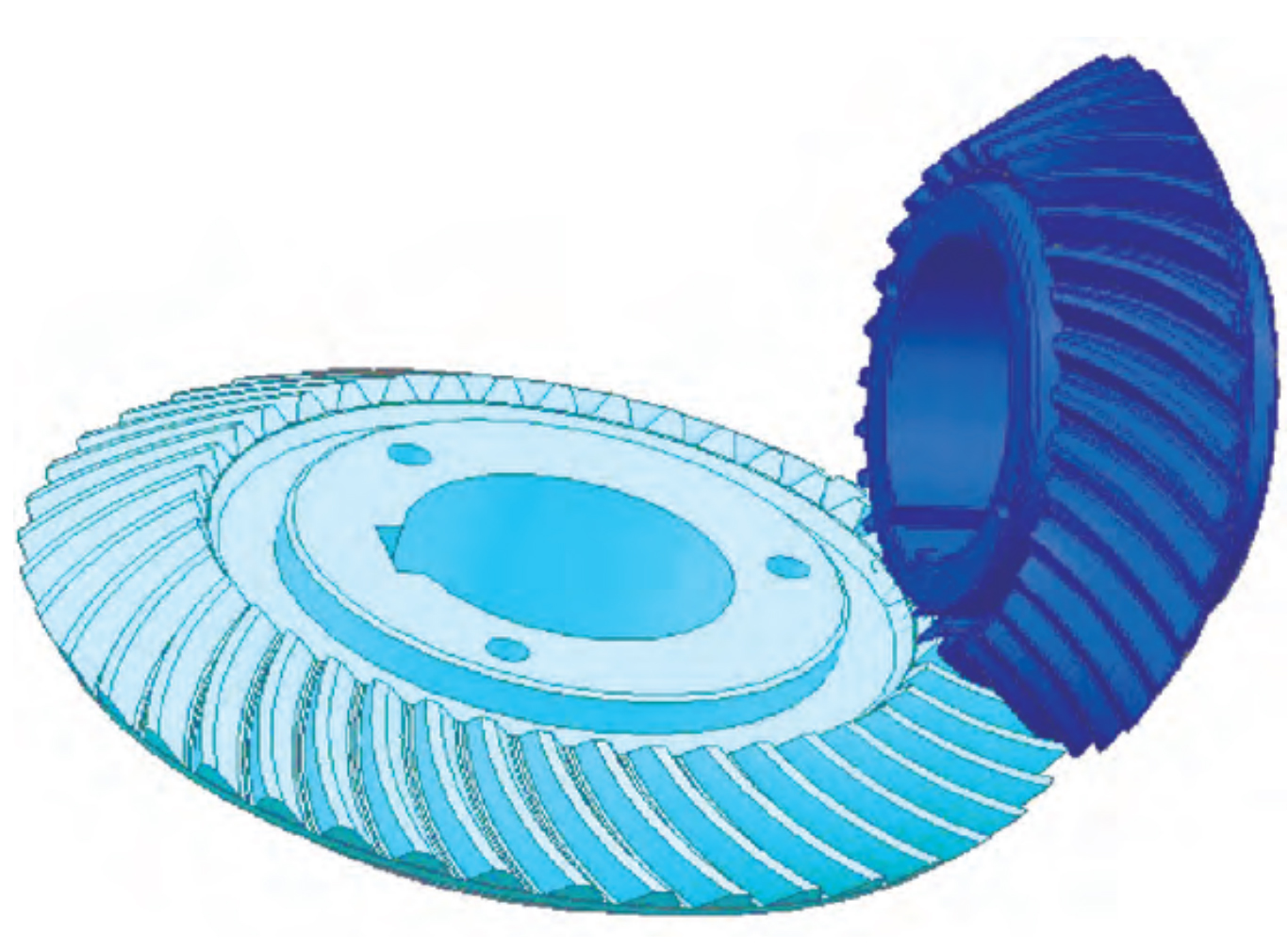

The free mode and contact mode of Gleason spiral bevel gear are analyzed. The mode of Gleason spiral bevel gear under steady-state condition is analyzed, and the contact stress, the first six vibration modes and natural frequencies of spiral bevel gear are obtained, and the following conclusions are drawn.

(1) The static analysis of the spiral bevel gear model verifies the rationality of its structure. The stress and deformation of spiral bevel gears are mainly concentrated in the contact area, followed by the compression side and tension side of the root area. After the root crack, the maximum displacement with crack is greater than that without crack; Small cracks have little effect on the contact stress. The stress concentration of the cutting edge leads to a sudden change in the stress value of the tooth root. The stress value near the crack tip is larger than that without cracks. When the transmission starts to mesh, the maximum stress of the spiral bevel gear mesh occurs at the root of the gear tooth. The contact ratio of spiral bevel gear pair is large, the front end carries three teeth, and the small crack has little effect on the stress value.

(2) The natural frequency and vibration model of spiral bevel gear system under contact condition are analyzed. Compared with free mode analysis, external load is not the key factor affecting the mode, but its influence cannot be ignored. The natural frequency increases with the increase of structural stiffness. The first frequency of contact mode is 389 2Hz, higher than the steady-state working frequency of spiral bevel gear, so resonance will not occur. The design of spiral bevel gear has good dynamic characteristics. The modal analysis results provide a theoretical basis for the structural design and further research of spiral bevel gear dynamics, and also provide a reference basis for the structural optimization and noise control of spiral bevel gear.