The precision forging process of spiral bevel gear generally has some problems, such as difficult forming, difficult cavity filling, low die life and difficult product quality assurance. Therefore, exploring reasonable forming methods, improving filling performance, reducing deformation force and ensuring die life is the focus of current research. The design and optimization of forging process of spiral bevel gear should be studied from each stage of production.

From the perspective of billet making process, selecting appropriate production equipment or production process can significantly improve production efficiency and reduce production cost. At present, the application of rolling forming process in the manufacturing of gear blank is becoming more and more popular. The research shows that the rolling forming process has small load and low vibration noise. It not only has simple equipment, but also greatly improves the working environment of workers. In addition, swing rolling, casting rolling and other processes are gradually used in the processing of gear blank; The optimization of blank making process can also start with the blank itself. Through theoretical analysis and data optimization methods, the most reasonable blank shape and size scheme can significantly improve the metal flow filling in the forging process and reduce the forging energy consumption.

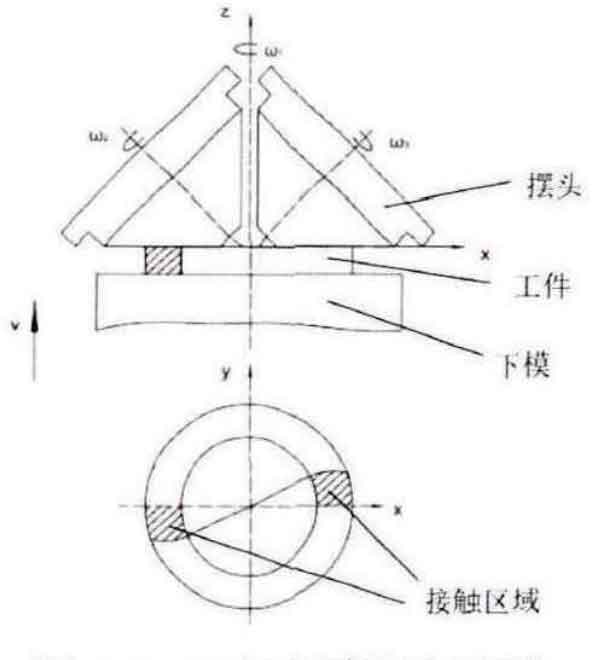

Grzegorz uses the cold precision forging process of rotary forging to form aluminum alloy bevel gears. The forming aspects are analyzed by the combination of numerical simulation and experiment. Song Jinsheng studied the process of forging and ring rolling gear blank. Through comparison, it is found that ring rolling process has more advantages in saving energy, saving materials, improving production efficiency and ensuring die life. Cheng mengbiao studied the forming process of gear blank, improved and optimized it, used the sizing die with 45 ° inclination to calibrate the blank after punching, prepared for the subsequent ring rolling steps, and swing rolled the formed ring with semi closed double cone roll, The upper surface flash of the gear blank processed by this process is very small or even no flash, which improves the forming quality and accuracy. Gao Bo proposed to form spiral bevel gear by double roll rotary forging process. The principle is shown in Figure 1. He studied the influence of process parameters on the forming effect of double roll rotary forging and provided a theoretical reference for the research of double roll rotary forging technology.

From the perspective of heat treatment process, reasonable heat treatment process can significantly improve the internal microstructure and mechanical properties of steel and prolong the service life of parts. However, due to the action of thermal stress and structural stress, the material will inevitably deform. At present, many manufacturing enterprises continue to explore the optimization scheme of heat treatment process by introducing new processes and equipment, so as to promote the environmental protection and intelligence of gear heat treatment process. The commonly used heat treatment processes of automobile gears include carburizing, carbonitriding and induction quenching. At present, new processes and technologies such as laser quenching and rare earth carburizing also show broad development prospects.

From the perspective of post-treatment process, reasonable post-treatment process can improve the precision and guarantee the performance of parts. For example, adding a cold extrusion after forging or surface sandblasting after heat treatment can significantly improve the quality accuracy of spiral bevel gears.

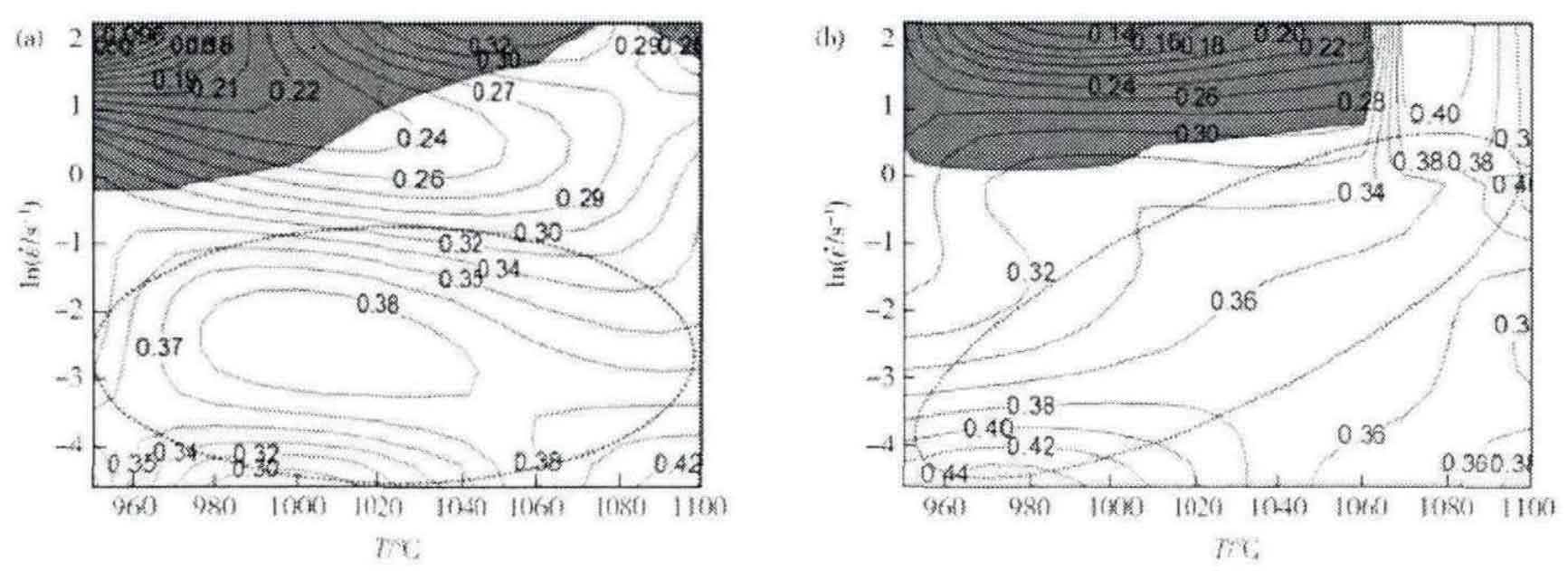

From the perspective of process parameters, deformation temperature and deformation rate have a significant impact on the processing properties of materials. Through the thermal simulation experiment of materials, the effects of deformation conditions such as temperature and speed on plastic deformation behavior can be studied, and through the observation of microstructure under different deformation conditions, Study the microstructure changes, select the appropriate forging process parameters and establish an accurate material model according to the results of material experiments. At present, many scholars have studied the constitutive model and microstructure of gear steel, and provided guidance for practical production, Zhu Xiaoxing and so on. The high temperature deformation behavior of gear steel SAE8620H was studied through high temperature compression test. The hyperbolic sinusoidal equation was used to describe the constitutive equation, and the hot working diagram of the gear steel was constructed (as shown in Figure 1); Tang Haiyan et al. Studied the high temperature hot deformation behavior and microstructure of Cr Co Mo Ni gear steel, established the constitutive model and hot working diagram of hot deformation process, and selected the appropriate initial forging temperature for die forging as 1000-1100 ° C and 15 forging passes; Peng Ningqi et al. Proposed a correction method of thermal compression rheological stress curve, which can effectively correct the error of experimental data.

The research on the optimization of process parameters can also focus on the lubrication of forging process. An appropriate amount of lubricant can improve product quality, prolong die life, save energy and produce good economic and social benefits.