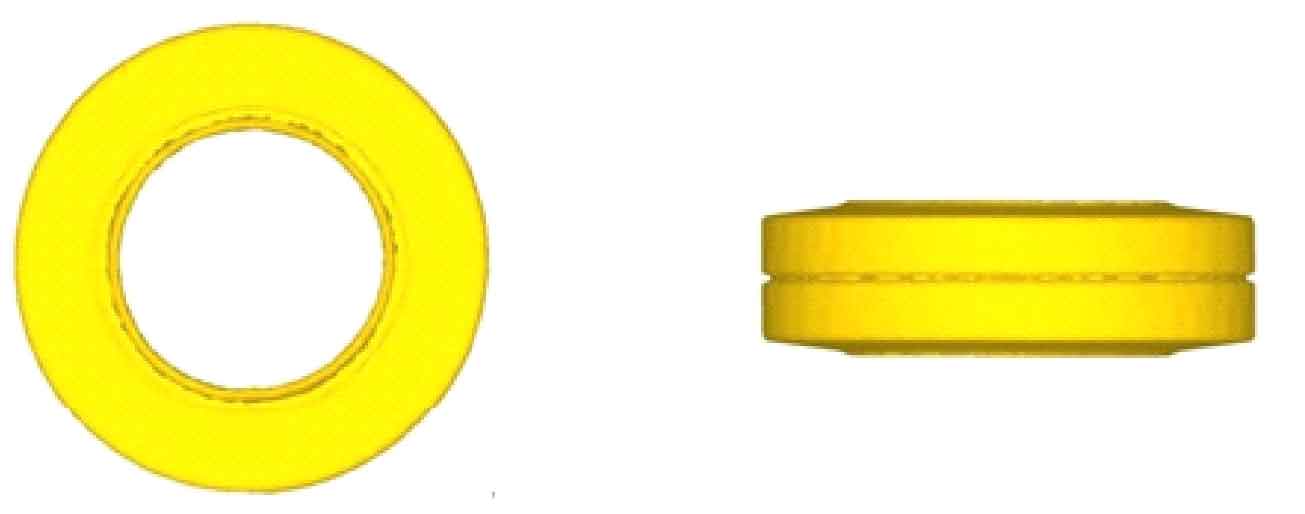

The spiral bevel gear blank formed by the two-piece ring rolling process, that is, the two spiral bevel gear blanks are connected at the bottom of the ring, and a 1mm groove is left in the middle to facilitate cutting and positioning. Then, two spiral bevel gear blanks can be obtained by cutting the groove through the grinder. The geometry of the formed spiral bevel gear blank is shown in Figure 1, and the geometric dimensions are shown in table.

It can be seen from Figure 1 that the geometry of the formed ring is consistent with the actual shape of the forging. The data in the table shows that the size of the formed ring meets the requirements of the actual size of the forging. Therefore, both the geometry and the formed size meet the requirements of the actual forging.

| Outer diameter (mm) | Inner diameter (mm) | Height (mm) |

| 179.9 | 112.1 | 56 |

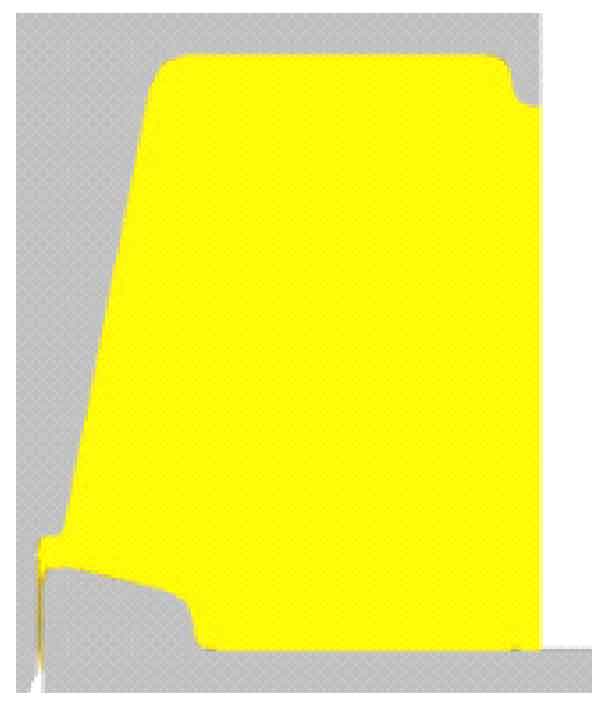

The existence of defects is one of the key factors to judge the quality of formed rings. Figure 2 is the cross-sectional view of formed rings. It can be seen from the figure that there are no defects such as insufficient filling at the fillet and “fishtail”, so the forming condition is good.

Through the analysis of the stress and strain distribution, geometric size, forming shape and defects of the two-piece ring rolling forging of spiral bevel gear blank, it is concluded that the new process of spiral bevel gear blank two-piece ring rolling can be realized in theory.