In order to ensure the machining accuracy of involute profile of gear shaft, milling must be carried out in strict accordance with the machining process.

1) After the gear shaft blank is processed, the fitter shall mark the number of teeth according to the drawing for indexing, and draw the tooth profile processing lines of all teeth according to the overall tooth profile template.

2) Rough machining shall be carried out on the boring and milling machine with a rod milling cutter according to the tooth profile drawn by the fitter, and 4 ~ 5mm quenching and tempering allowance shall be reserved on the tooth surface.

3) The quenching and tempering treatment meets the technical requirements.

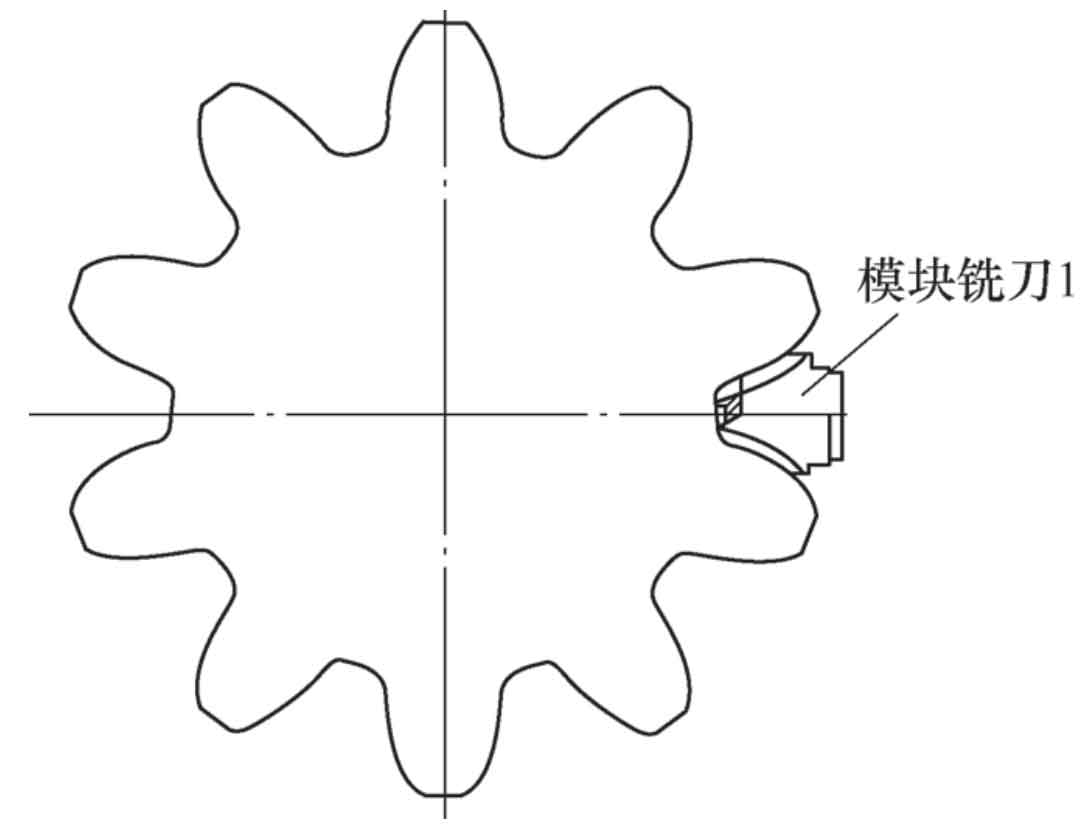

4) On the boring and milling machine, the indexing head is used to index the gear shaft, the designed first milling cutter is used to mill a part of the tooth profile at the root of the tooth profile, and then the indexing is carried out according to the number of teeth, and the tooth profile of the root of all teeth is milled in turn. As shown in Figure 1.

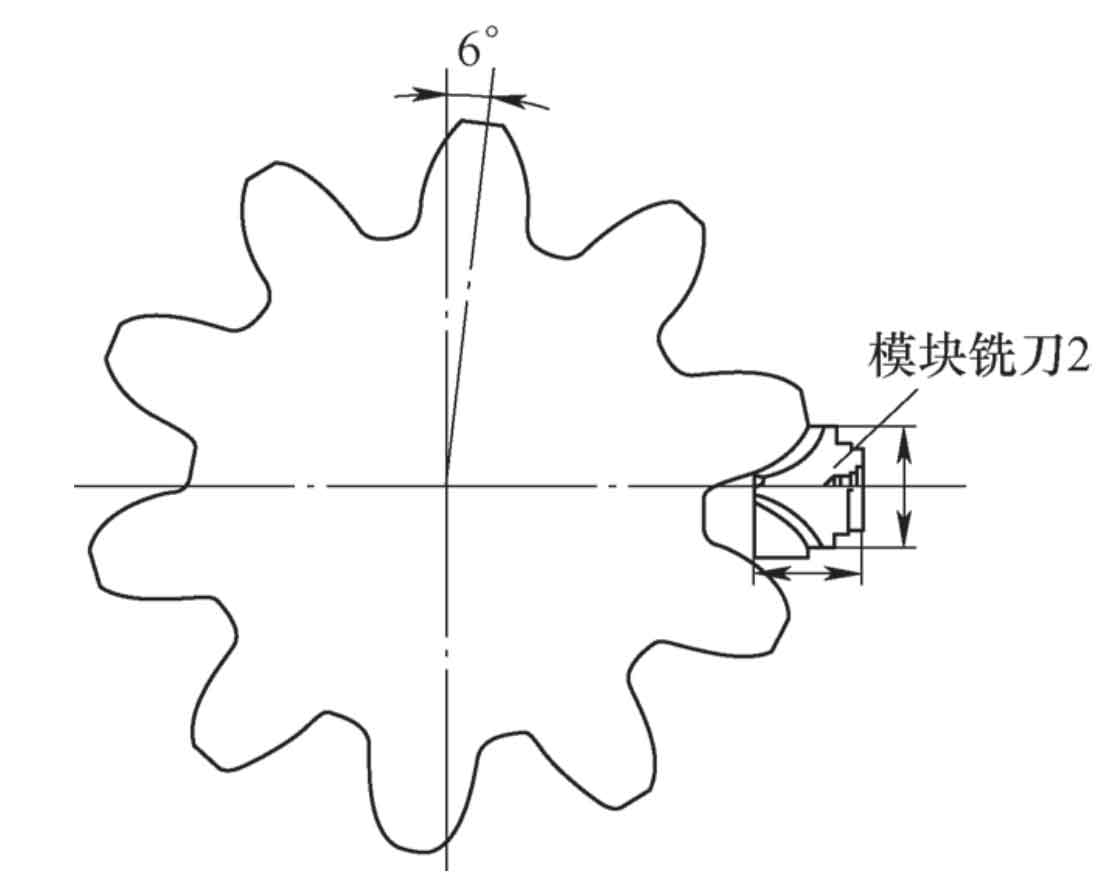

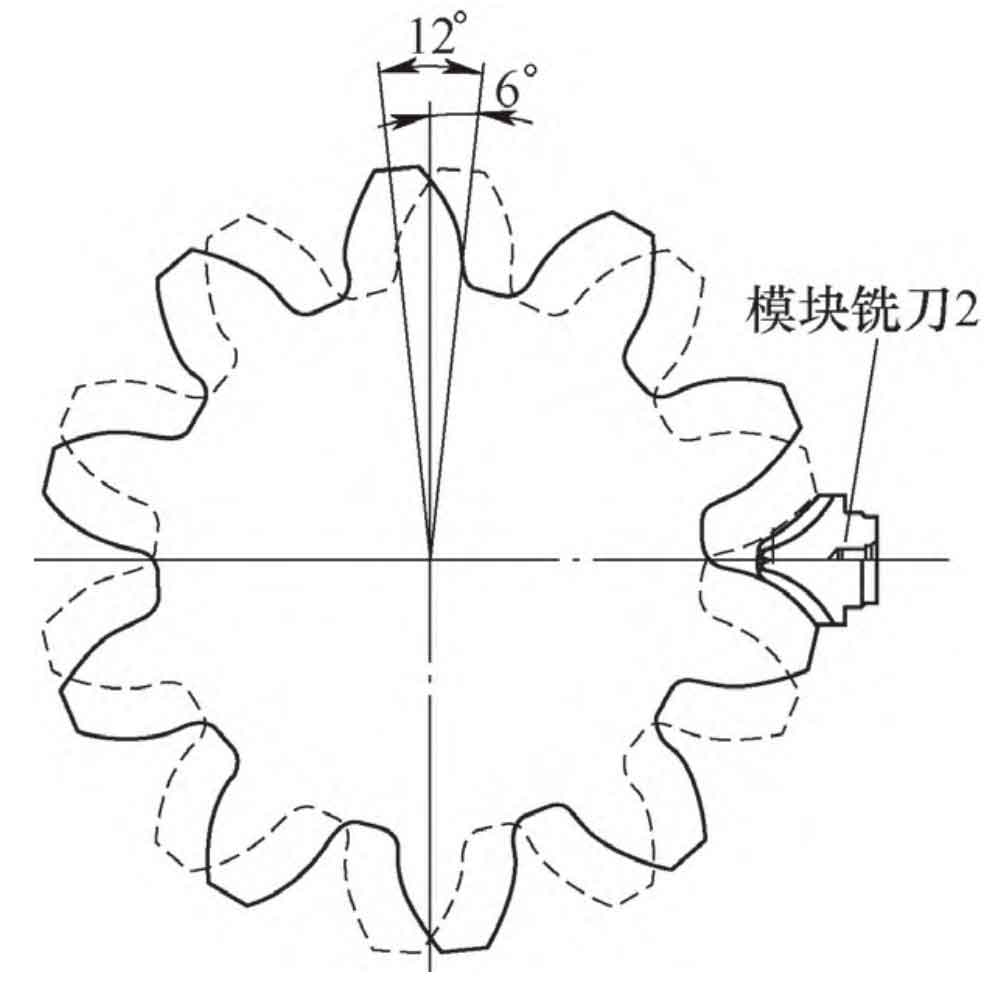

5) When the tooth profile of the root of all teeth is milled, replace the second milling cutter. Rotate the indexing head, rotate the gear shaft by 6 °, and the position of the milling cutter remains unchanged (see Fig. 2). Use the second milling cutter to mill the remaining part of the tooth profile. At this time, only one side of one tooth is processed. After the single side of one tooth is processed, use the dividing head again to divide and process the single side of all teeth according to the number of teeth. Since this processing is one-sided cutting, the gear shaft should be positioned accurately and clamped firmly. The gear shaft is not allowed to rotate in the processing process. Otherwise, the tooth profile will change seriously and can not meet the accuracy requirements of involute tooth profile. When the tooth profile of one side is processed, rotate the gear shaft in the opposite direction by 12 °, and the milling cutter position remains unchanged (see Fig. 3). Process the tooth profile of the other side according to the above processing steps.

6) As a complete tooth profile is processed in two times, steps are easy to appear at the connection of two knives, and the fitter is required to grind the tool connection of two sections of tooth profile to make the transition of involute tooth profile smooth.