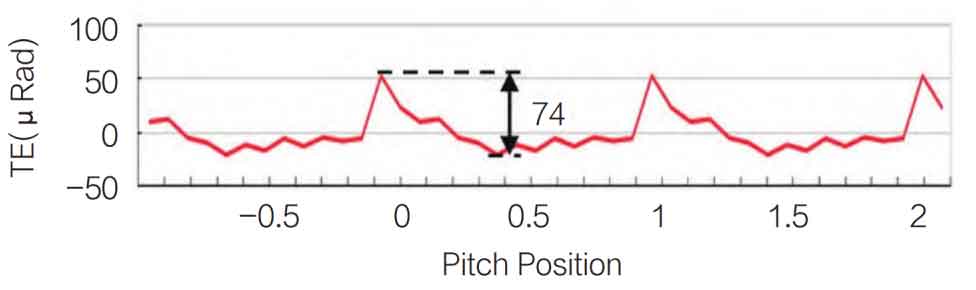

The vibration acceleration amplitude and gear transmission error of the main gear bearing before and after optimization are simulated and analyzed by using the established Masta power transmission system analysis model. The peak value of vibration acceleration decreases from 168m / S2 to 24m / S2, with a decrease of 85.7%. See Fig. 1a-b for details; The transmission error of gears is determined by 126 μ Rad drops to 74 μ Rad, down 41.3%, see figure 2a-b for details.

According to the optimization results, the prototype is made for real vehicle test. Acoustic microphones are arranged at the rear of the whole vehicle, and LMS equipment is used to collect the internal noise of the vehicle under the condition of full throttle acceleration with engine speed of 1500 ~ 4000R / min. through the test The order noise of rear axle gear is extracted by lab software.

The test results show that the noise peak appears at the engine speed of 3120r / min, and the maximum decibel value is 67.64db (a), which exceeds the target line. After optimization, there is no noise peak in the full speed range, and the overall noise is lower than the target line, achieving the optimization effect, as shown in Fig. 3a-b.