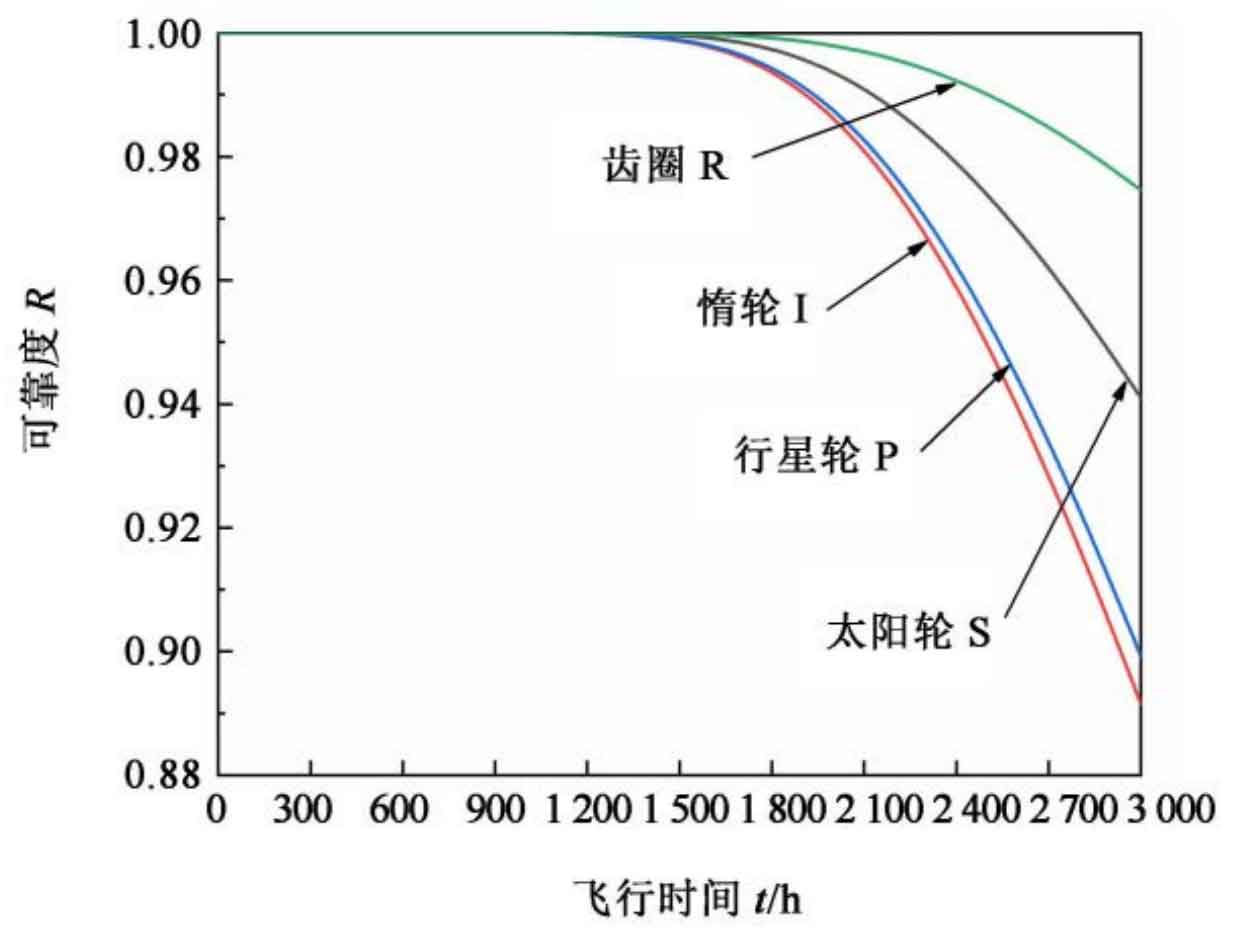

In order to accurately evaluate the reliability variation law of gear transmission system of flying vehicle, 3000 h reliability is selected as the reliability evaluation index. The design life index conforms to the TBO life range commonly used in aviation transmission system. A single gear reliability model considering contact and bending fatigue failure is established by using copula function, and the variation law of reliability of gear components in automobile gear transmission system is obtained, as shown in Figure 1.

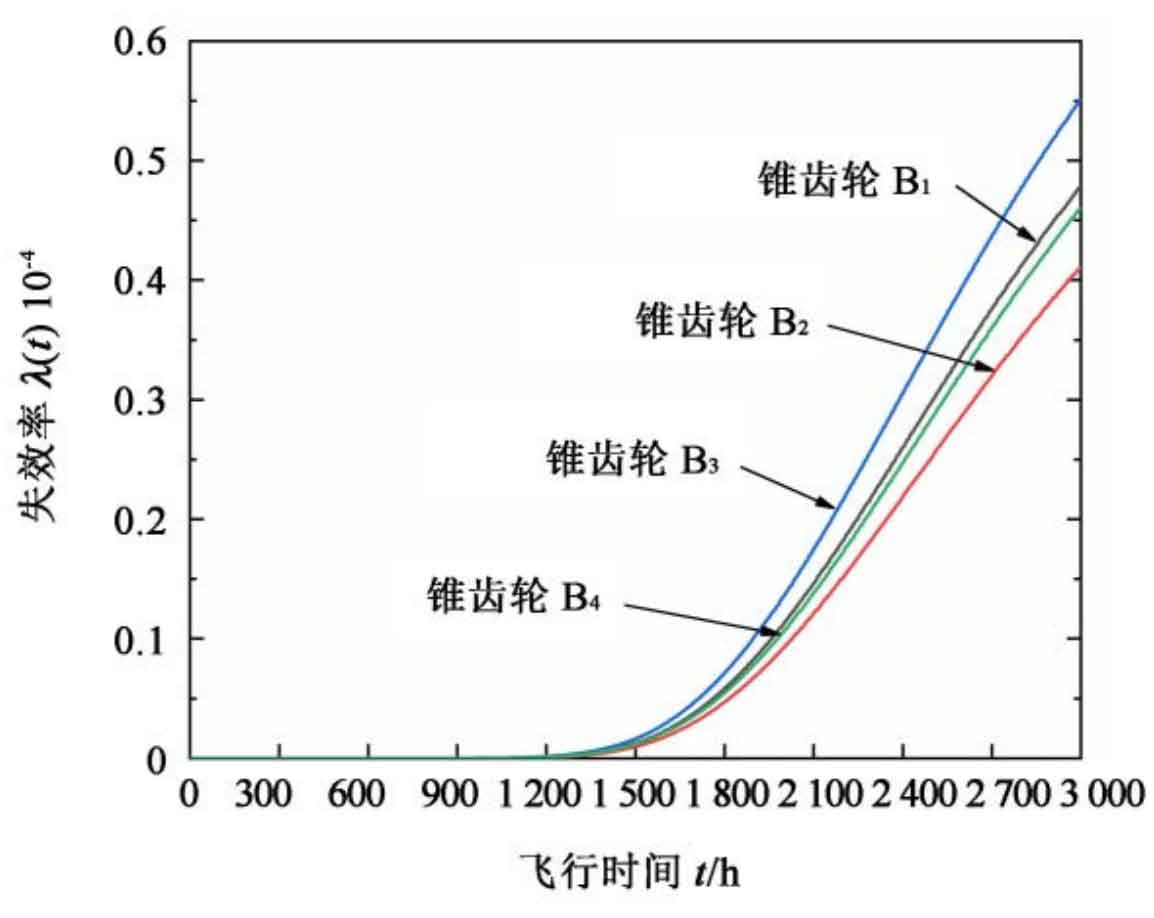

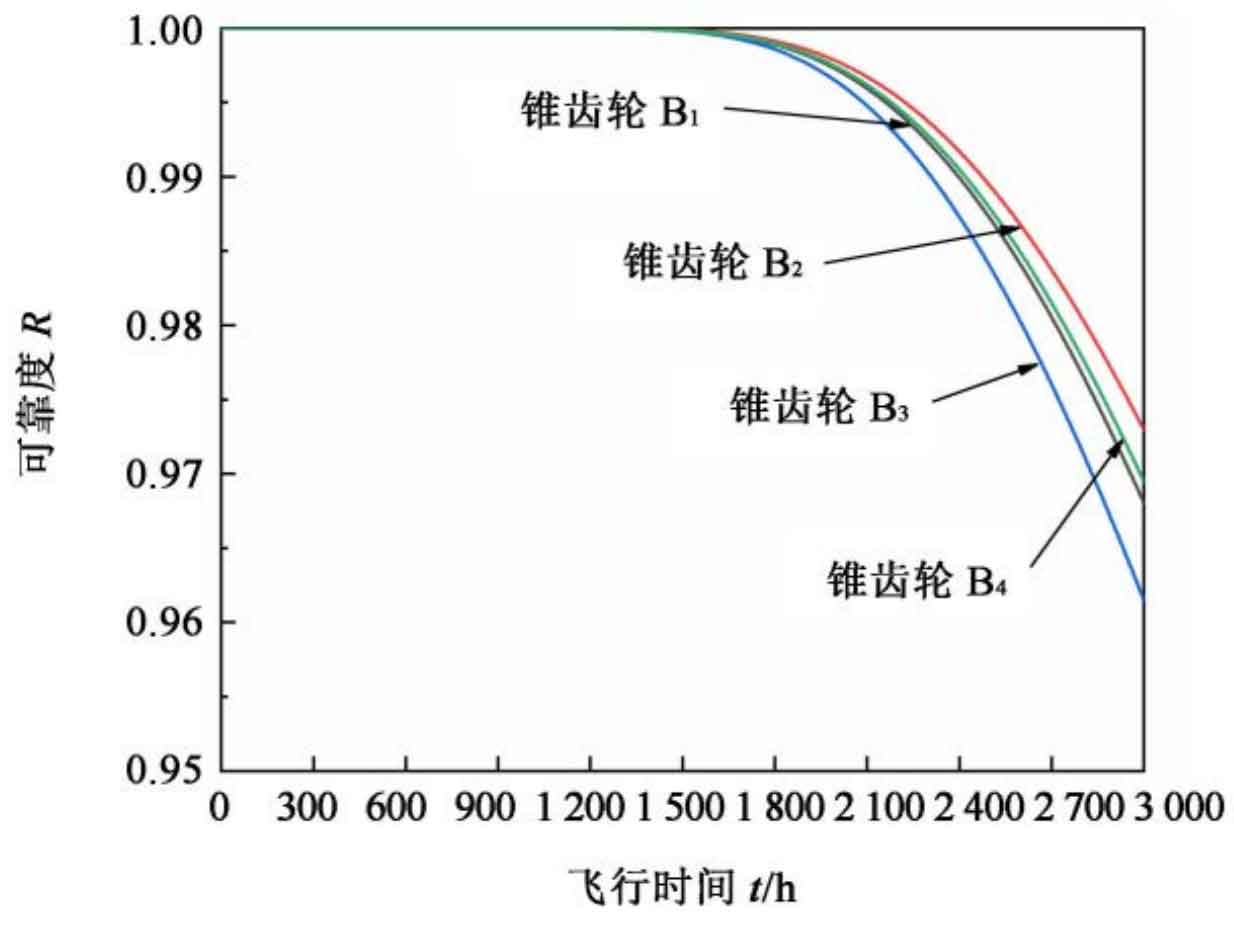

Due to the influence of automobile gear strength degradation during service, the reliability of various parts in the automobile gear transmission system shows a trend of nonlinear decline. In the first 1200 h, the reliability has almost no attenuation, and in the last 1800 h, the downward trend of reliability increases obviously. Among them, the reliability of idler gear I and planetary gear P has the fastest downward trend, and the ring gear R has the slowest downward trend. In the service process, the reliability of each gear in the gear system is ranked from large to small as follows: ring gear R, bevel gear B2, bevel gear B4, bevel gear B1, bevel gear B3, sun gear s, planetary gear P and idler gear I. The reliability of each gear in the gear transmission system of the flying vehicle varies greatly, which does not meet the requirements of equal strength design, and there is room for further optimization.

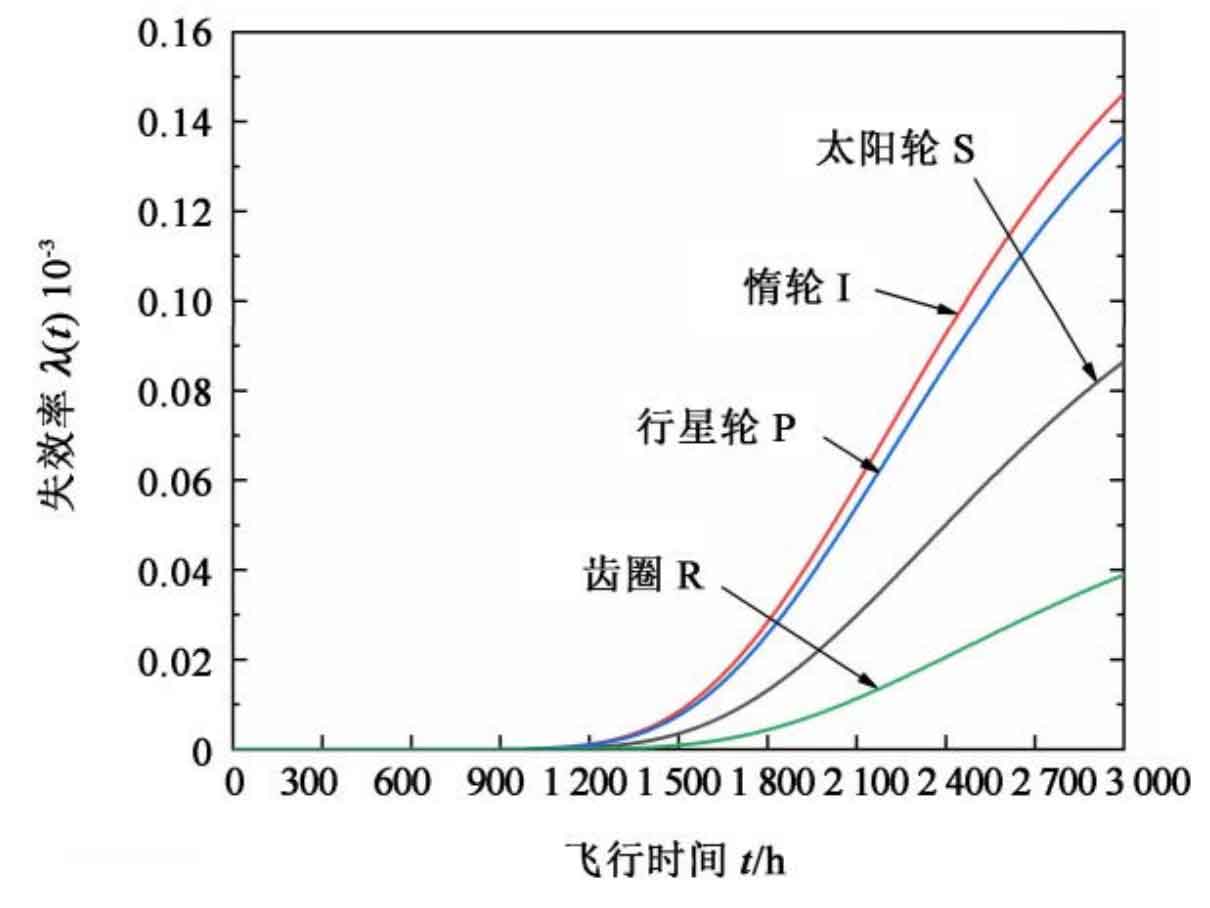

The failure rate change curve of each component in the automobile gear transmission system is shown in Figure 2. At the beginning of service, the strength degradation of automobile gears is less and the failure rate is low; In the middle and later period of service, with the acceleration of strength degradation, the failure rate also increases gradually, which is in line with the characteristics of wear failure period in the “bathtub curve”. Among them, the failure rate of idler gear I and planetary gear P is the highest, and the failure rate of ring gear R is the lowest.