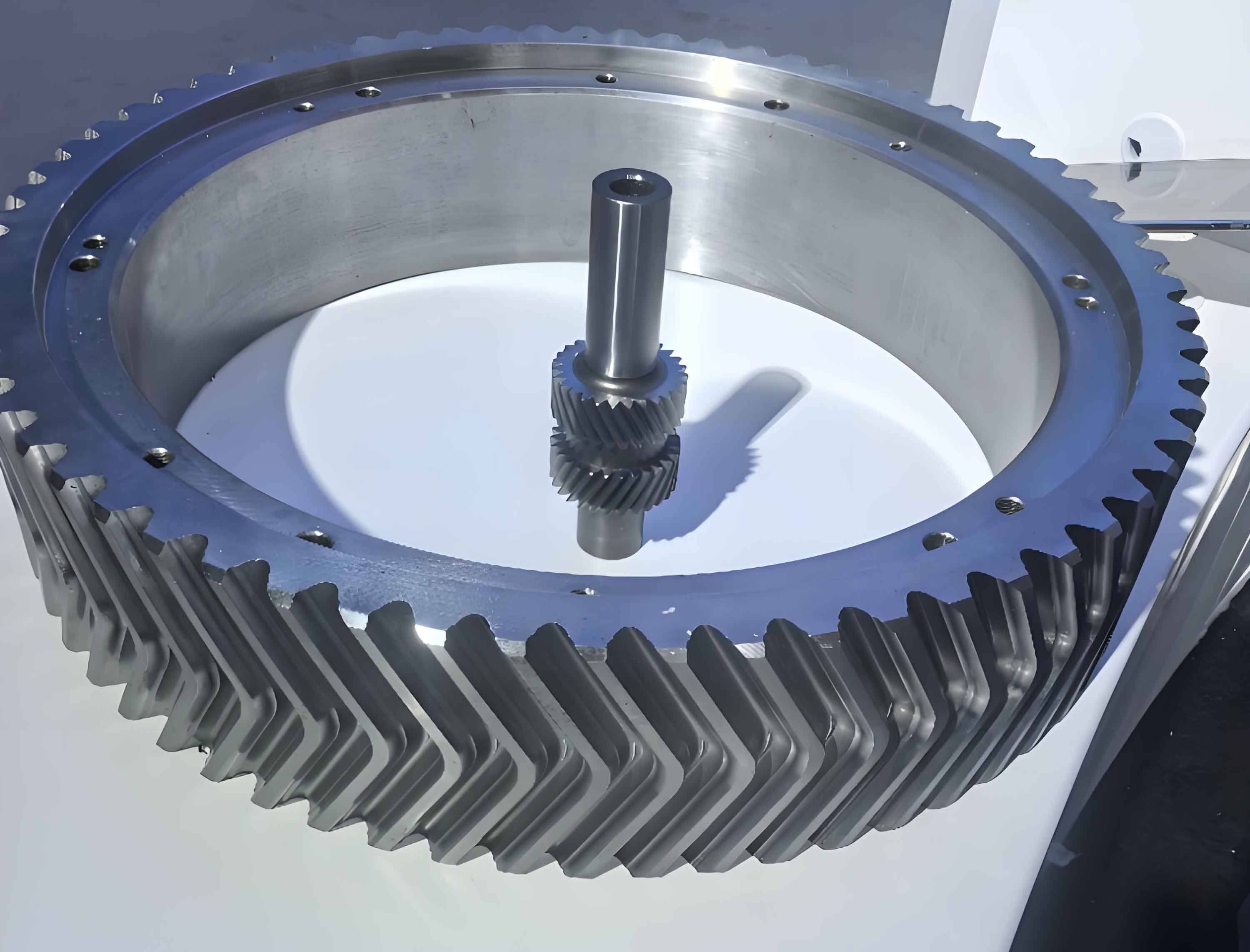

In the field of heavy machinery manufacturing and maintenance, herringbone gears play a critical role due to their unique ability to handle high torque loads with minimal axial thrust. These gears, characterized by their V-shaped tooth arrangement, are essential components in various industrial applications, such as steel mills, where precision and durability are paramount. Recently, our company faced a challenging situation involving the repair of a large herringbone gear with bore over-tolerance issues. This experience highlighted the intricacies of herringbone gears and the innovative approaches required for their restoration. Throughout this article, I will delve into the details of this repair process, emphasizing the technical considerations and methodologies employed. The term ‘herringbone gears’ will be frequently referenced to underscore their significance in this context.

The incident occurred during the fine machining of a large herringbone gear intended for a steel plant’s maintenance spare parts. The gear structure consisted of two key bores: a larger bore and a smaller bore, each with specific dimensional tolerances. During the machining process, an operator mistakenly identified the smaller bore as the larger one, leading to an incorrect cutting operation that resulted in severe over-tolerance of the smaller bore. Specifically, the smaller bore was machined to a diameter larger than the specified H7 tolerance, rendering the herringbone gear unusable without repair. This error posed a significant challenge, as the herringbone gear’s functionality depends on precise bore alignments to ensure proper meshing and load distribution. The material of the gear was ZG270-500, a cast steel with moderate weldability, which further complicated the repair options.

Upon assessment, we considered multiple repair strategies. One option was to modify the larger bore to match the smaller bore’s intended size, but this would alter the herringbone gear’s helical direction, affecting the entire machine design and force distribution. Therefore, this approach was deemed impractical. Instead, we decided to preserve the accurately machined larger bore and repair the over-tolerance smaller bore through welding. This decision was driven by the need to maintain the original design integrity of the herringbone gears, ensuring they perform as intended in the system. The repair focused on minimizing distortion and achieving a weld quality that meets the gear’s operational requirements.

The repair process was meticulously planned and executed in several steps. First, the herringbone gear was positioned horizontally with the smaller bore facing downward. A thin steel plate was placed at the interface between the bores to prevent welding spatter from entering the larger bore. Next, the larger bore was filled with quick-drying sand (or clay as an alternative) to act as a support and minimize thermal distortion during welding. The gear was then mounted on a large lathe for rotational welding, which allowed for consistent weld deposition. We utilized CO₂ gas shielded welding with H08Mn2SiA焊丝 (copper-coated wire of 1.2 mm diameter), selected for its compatibility with the base material and its deoxidizing properties, enhancing weld quality.

Pre-welding preparations included preheating the smaller bore to 150–250°C using a flame to reduce thermal stress. The welding parameters were optimized for low heat input: current of 90–110 A, voltage of 20–22 V, and direct current reverse polarity. We employed a single-pass welding technique to reduce joints and associated defects. During welding, continuous peening of the weld bead was performed to relieve residual stresses, a crucial step for herringbone gears to prevent cracking. Post-welding, the gear was covered with lime for slow cooling, mitigating brittleness. After reaching room temperature, the sand and steel plate were removed, and the bore was remachined to the specified H7 tolerance. This method proved effective, as magnetic particle inspection revealed no defects such as porosity, slag inclusions, or cracks, confirming the repair’s success.

To provide a deeper understanding, let’s explore the technical aspects of herringbone gears and welding repair. Herringbone gears are designed with opposing helical teeth that cancel axial forces, making them ideal for high-load applications. The geometry involves parameters like module, pressure angle, and helix angle, which influence performance. For instance, the module (m) can be expressed as: $$ m = \frac{d}{z} $$ where \(d\) is the pitch diameter and \(z\) is the number of teeth. Additionally, the helix angle (\(\beta\)) affects the gear’s contact ratio and smoothness of operation. In our repair, maintaining these geometric properties was essential to ensure the herringbone gears function correctly post-repair.

Welding repair of herringbone gears requires careful control of heat input to avoid distortion. The heat input (Q) can be calculated using: $$ Q = \frac{V \times I}{v} $$ where \(V\) is voltage, \(I\) is current, and \(v\) is the welding speed. For our case, with parameters of 20 V, 100 A, and a speed of 10 mm/s, the heat input was approximately: $$ Q = \frac{20 \times 100}{10} = 200 \, \text{J/mm} $$ This low heat input helped minimize thermal effects on the gear’s structure. Below is a table summarizing the welding parameters used in the repair of herringbone gears:

| Parameter | Value | Description |

|---|---|---|

| Welding Method | CO₂ Gas Shielded Welding | Provides protection against oxidation |

| 焊丝 Material | H08Mn2SiA | Compatible with ZG270-500, enhances deoxidation |

| 焊丝 Diameter | 1.2 mm | Ensures stable arc and deposition |

| Current (I) | 90–110 A | Low current to reduce heat input |

| Voltage (V) | 20–22 V | Maintains arc stability |

| Preheat Temperature | 150–250°C | Reduces thermal stress and cracking risk |

| Post-weld Cooling | Lime Covering | Slow cooling to prevent brittleness |

The repair of herringbone gears also involves considerations for material properties. ZG270-500 has a carbon equivalent (CE) that influences weldability. The carbon equivalent can be estimated using the IIW formula: $$ \text{CE} = \text{C} + \frac{\text{Mn}}{6} + \frac{\text{Cr} + \text{Mo} + \text{V}}{5} + \frac{\text{Ni} + \text{Cu}}{15} $$ For ZG270-500, typical values are C=0.27%, Mn=0.50%, leading to a CE of approximately 0.35%, indicating moderate weldability. This necessitated preheating and controlled cooling to avoid hydrogen-induced cracking, a common issue in herringbone gears repair.

Beyond the specific case, herringbone gears are subject to various failure modes, such as wear, pitting, and bore distortion. Preventive measures include regular inspection and proper machining tolerances. The bore tolerance for herringbone gears is critical; for H7 tolerance, the diameter range is tightly controlled. For example, for a nominal diameter of 335 mm, the H7 tolerance limits are: $$ \text{Upper Limit} = 335.000 + 0.025 \, \text{mm} $$ $$ \text{Lower Limit} = 335.000 \, \text{mm} $$ In our repair, the over-tolerance bore exceeded these limits, necessitating the welding process to restore it. The success of this repair underscores the importance of precision in herringbone gears manufacturing.

To further elaborate on herringbone gears design, let’s consider the contact stress analysis. The Hertzian contact stress (\(\sigma_H\)) between gear teeth can be calculated as: $$ \sigma_H = \sqrt{\frac{F}{\pi b} \cdot \frac{1}{\frac{1-\nu_1^2}{E_1} + \frac{1-\nu_2^2}{E_2}} \cdot \frac{1}{\rho}} $$ where \(F\) is the normal load, \(b\) is the face width, \(\nu\) is Poisson’s ratio, \(E\) is Young’s modulus, and \(\rho\) is the equivalent radius of curvature. For herringbone gears, the double helical design distributes loads evenly, reducing stress concentrations. During repair, ensuring the bore alignment preserves this stress distribution is vital for the longevity of herringbone gears.

In terms of welding quality control, non-destructive testing (NDT) methods are essential. Magnetic particle inspection, as used in our case, is effective for surface defects. For subsurface defects, ultrasonic testing might be employed. The acceptance criteria for herringbone gears welds typically require no linear defects exceeding 3 mm. Below is a table comparing NDT methods for herringbone gears repair:

| NDT Method | Detection Capability | Advantages | Limitations |

|---|---|---|---|

| Magnetic Particle | Surface cracks and defects | Quick and cost-effective | Only for ferromagnetic materials |

| Ultrasonic Testing | Subsurface defects | Deep penetration, precise sizing | Requires skilled operators |

| Radiographic Testing | Internal voids and inclusions | Provides permanent record | Safety hazards from radiation |

The economic and operational benefits of this repair approach are significant. Compared to traditional arc welding, the CO₂ welding process reduced costs by 30% and increased welding speed by 50%. Moreover, the use of rotational welding on a lathe minimized manual labor, enhancing productivity. For herringbone gears, such efficiencies are crucial in maintenance scenarios where downtime must be minimized. This repair method can be adapted for other large gears, but herringbone gears require special attention due to their complex geometry.

Looking forward, advancements in additive manufacturing could revolutionize the repair of herringbone gears. Techniques like directed energy deposition might allow for precise material addition without extensive heat input. However, for now, conventional welding remains a reliable option. In conclusion, the successful repair of the herringbone gear bore over-tolerance demonstrates the importance of tailored welding strategies, thorough planning, and quality assurance. Herringbone gears, with their unique design, demand meticulous care in restoration to ensure operational reliability. This experience has enriched our expertise in handling such critical components, reinforcing the value of innovation in industrial maintenance.

To summarize key points, herringbone gears are indispensable in heavy machinery, and their repair involves balancing technical constraints with practical solutions. The repair process highlighted here—using CO₂ welding with protective measures—offers a model for similar challenges. By integrating formulas, tables, and detailed analysis, we can better understand and address the complexities of herringbone gears in engineering applications. As industries evolve, the lessons from this case will continue to inform best practices for maintaining and repairing herringbone gears, ensuring their performance in demanding environments.