1. Introduction

Spiral bevel gear play a crucial role in many mechanical systems, especially in those requiring high power transmission and precise motion control. The performance and durability of these gears are of great importance. One effective method to enhance their fatigue life and mechanical properties is through shot peening. Shot peening induces residual compressive stress on the gear surface, which can significantly improve the contact fatigue strength, bending fatigue strength, and anti-scuffing ability of the gears.

1.1 Importance of Spiral Bevel Gear

Spiral bevel gear is widely used in various industries such as automotive, aerospace, and industrial machinery. They are essential components for transmitting power between intersecting shafts at different angles. The complex geometry and high load-carrying requirements of spiral bevel gear make their design, manufacturing, and performance optimization a challenging task.

1.2 Role of Shot Peening in Gear Enhancement

Shot peening is a surface treatment process that involves bombarding the surface of a part with small spherical media (shot) at high velocities. This process causes plastic deformation of the surface layer, resulting in the generation of residual compressive stresses. For spiral bevel gear, these residual compressive stresses can counteract the tensile stresses induced during operation, thereby increasing the fatigue life and reducing the likelihood of crack initiation and propagation.

2. Experimental Setup for Shot Peening of Spiral Bevel Gear

2.1 Gear Material and Preparation

The spiral bevel gear used in the experiment were made of AISI 9310 high-strength alloy steel. The spiral bevel gear teeth were subjected to carburizing and quenching processes to achieve a high surface hardness. The surface hardness within a depth of 0.56 mm from the tooth surface was higher than 60HRC.

2.2 Shot Peening Equipment and Parameters

The shot peening process was carried out using an MP1000Ti CNC shot peening machine. The key parameters of the shot peening process are as follows:

| Parameter | Value |

|---|---|

| Shot Type | ASH110 (55 – 62HRC) |

| Shot Peening Intensity | 0.178 – 0.228 mmA |

| Coverage | 200% |

| Nozzle Angle | 17° |

| Air Pressure | 0.25 MPa |

| Nozzle Movement Speed | 70 mm/min |

| Shot Peening Time | 144 s |

| Gear Rotation Speed | 30 r/min |

| Shot Flow Rate | 5 kg/min |

2.3 Residual Stress Measurement

Residual stress measurements were performed on spiral bevel gear tooth surfaces. The measurement points were located on the tooth surface pitch cone line, with a, b, and c being the quarter points of the tooth width, and a being closer to the large end of the tooth. The electrolytic polishing method was used to gradually remove the surface layer along the normal direction of the tooth surface to obtain the residual stress distribution at different depths. The X-ray diffraction method was employed to measure the residual stress. The measurement parameters were as follows:

| Parameter | Value |

|---|---|

| Tube Voltage | 25 kV |

| Tube Current | 5 mA |

| X-ray Tube | Cr_K – Alpha |

| Aperture Diameter | 1 mm |

| Wavelength | 2.291 A |

| Exposure Time | 3 s |

| Exposure Number | 7 |

| Maximum β Angle | 20° |

3. Simulation Model for Shot Peening of Spiral Bevel Gear

3.1 Discrete Element Model (DEM)

The DEM was used to simulate the motion of the shot from the nozzle to spiral bevel gear tooth surface. The EDEM simulation software was utilized to set up the discrete element model.

3.1.1 Model Setup

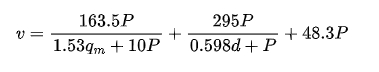

The geometric model of the shot peening process was established according to the actual process parameters. The nozzle was set to be perpendicular to spiral bevel gear tooth root, convex surface, and concave surface, and the distance from the target surface was 150 mm. The initial velocity of the shot was determined by an empirical formula:

where is the shot diameter (mm), is the shot flow rate (kg/min), and is the nozzle air pressure (MPa).

3.1.2 Data Extraction and Processing

The calculation results from EDEM were exported, and the impact point positions were determined using the unit number. The impact information on the tooth surface pitch cone line was screened and processed.

- Impact Velocity Vector: The absolute velocity of the shot was converted to the relative velocity with respect to the tooth surface unit. This conversion was based on the coordinate transformation principle.

- Impact Times: The unit area impact times at the target position were calculated using the formula , where is the impact times of the unit with the shot, is the unit area, and is the EDEM model calculation time.

3.2 Finite Element Model (FEM)

The FEM was used to calculate the residual stress field on spiral bevel gear tooth surface after shot peening. The ABAQUS/CAE commercial finite element software was employed for this purpose.

3.2.1 Mesh Generation and Boundary Conditions

The shot diameter was set to 0.3 mm, and the unit type was C3D8R. The target plate was divided into different regions with different mesh sizes. The mesh size in region I and II was , and region III was a transition area from fine to coarse mesh. Region IV was an infinite unit body CIN3D8 used to eliminate the reflection of stress waves at the boundary. The bottom surface of the target plate was completely fixed. The contact relationship between the shot and the target plate was set as Surface to Surface, with the normal behavior defined as “hard” contact and the tangential behavior defined as penalty friction with a friction coefficient of 0.2.

3.2.2 Material Model

The shot was modeled as an elastic-plastic body with an isotropic constitutive model. The material parameters of the shot were set as follows: Young’s modulus , Poisson’s ratio , density , and yield strength . The target body material was 9310 carburized and quenched steel. The material parameters were set as follows: Young’s modulus , Poisson’s ratio , density , and the plastic stress-strain curve was modeled using the Johnson – Cook model with parameters , , , , . To prevent stress wave oscillation, the target plate material damping was set as .

3.2.3 Shot Impact Information

The shot impact angle, velocity, and times were determined from the results of the DEM calculation. The shot was assumed to be spherical with a diameter of 0.3 mm. Considering the random distribution of the shot impact positions in actual situations, the Python language was used to generate random positions within region I of the target plate.

4. Results and Discussion

4.1 Comparison between Simulation and Experimental Results

To verify the accuracy of the simulation model, the same process parameters as in the experiment were set in the simulation model.

- Three-Dimensional Roughness: The measured value of the three-dimensional roughness on the convex surface after shot peening was 0.35 , and the simulation result was 0.386 , with an error of 10.3%. The difference in resolution between the simulation and experimental results was due to the different sampling spacings.

- Residual Stress: The comparison of the residual stress values in the tooth height direction on spiral bevel gear tooth surface after shot peening is shown in Table 1. The surface residual stress at each point of the tooth was between -800 and -880 MPa, with a calculation error within 6%. The distribution of the residual stress along the depth direction at point b on the convex and concave surfaces is shown in Figure 8. The results showed that the simulation model could accurately predict the residual stress field on spiral bevel gear tooth surface after shot peening.

4.2 Influence of Shot Peening Time

The shot peening coverage is affected by the shot flow rate and shot peening time. An increase in either of these parameters will increase the shot impact times and thus the coverage.

- Surface Residual Stress: As the shot peening time increased, the surface residual compressive stress on the target plate increased. When the shot peening time reached 72 s, it gradually stabilized at around 800 MPa.

- Residual Stress at Different Depths: The residual compressive stress at 10 depth showed a gradually increasing trend and stabilized after 96 s at about 1000 MPa. The residual compressive stress at 20 depth continued to increase, and after 72 s, it was higher than that at 10 depth, indicating that the maximum residual compressive stress depth increased from 10 to 20 .

4.3 Influence of Shot Velocity

The initial velocity of the shot is determined by the nozzle air pressure, shot flow rate, and shot diameter, with the nozzle air pressure being the main factor.

- Surface Residual Stress: As the shot velocity increased from 30 m/s to 40 m/s and 50 m/s, the surface residual compressive stress value changed slightly.

- Maximum Residual Compressive Stress: The maximum residual compressive stress value and depth increased. The maximum residual compressive stress values were -1104.7 MPa, -1144.9 MPa, and -1167.3 MPa, and the maximum residual compressive stress depths were 20 , 25 , and 30 respectively.

4.4 Influence of Shot Diameter

The calculation of the residual stress field under different shot diameters was carried out.

- Surface Residual Stress: As the shot diameter increased, the surface residual stress value changed slightly.

- Maximum Residual Compressive Stress: The maximum residual compressive stress value and depth increased significantly. When the shot diameter increased from 0.18 mm to 0.30 mm and 0.42 mm, the surface residual stress was between -760 and -840 MPa, the maximum residual compressive stress value increased from -893.6 MPa to -1145.0 MPa and -1251.5 MPa, and the maximum residual compressive stress depth increased from 10 to 30 and 40 respectively. However, an increase in shot diameter also increased the surface roughness of spiral bevel gear.

5. Conclusions

5.1 Accuracy of the Simulation Model

The simulation model established in this study for the shot peening process of spiral bevel gear based on the coupling of discrete element and finite element methods has a prediction error of less than 10% for the residual stress field on spiral bevel gear tooth surface, indicating its high accuracy.

5.2 Influence of Shot Peening Parameters

- Shot Peening Time: When the shot peening time is 72 s, the shot impact number reaches 360 per , and the target plate coverage reaches full coverage. As the shot peening time continues to increase, the surface compressive stress on the target plate gradually stabilizes at around -800 MPa.

- Shot Velocity and Diameter: When the shot coverage is 200%, changes in the shot diameter and velocity have a relatively small impact on the surface residual compressive stress of the parts used in this study. However, an increase in the shot initial velocity and diameter can significantly increase the maximum residual compressive stress value and depth on the target plate surface. The maximum residual compressive stress value can reach -1251.5 MPa, and the maximum residual compressive stress depth can reach 40 .

- Depth of Influence: The shot peening process mainly affects the residual stress field within a depth of 50 from the gear tooth surface. For depths greater than 50 , the residual stress field is determined by the pre-shot peening process.

In summary, this study provides a valuable tool and method for optimizing the shot peening process parameters of spiral bevel gear, which can help improve the performance and durability of these important mechanical components. Future research could focus on further refining the simulation model and exploring the effects of other factors on the shot peening process of spiral bevel gear.