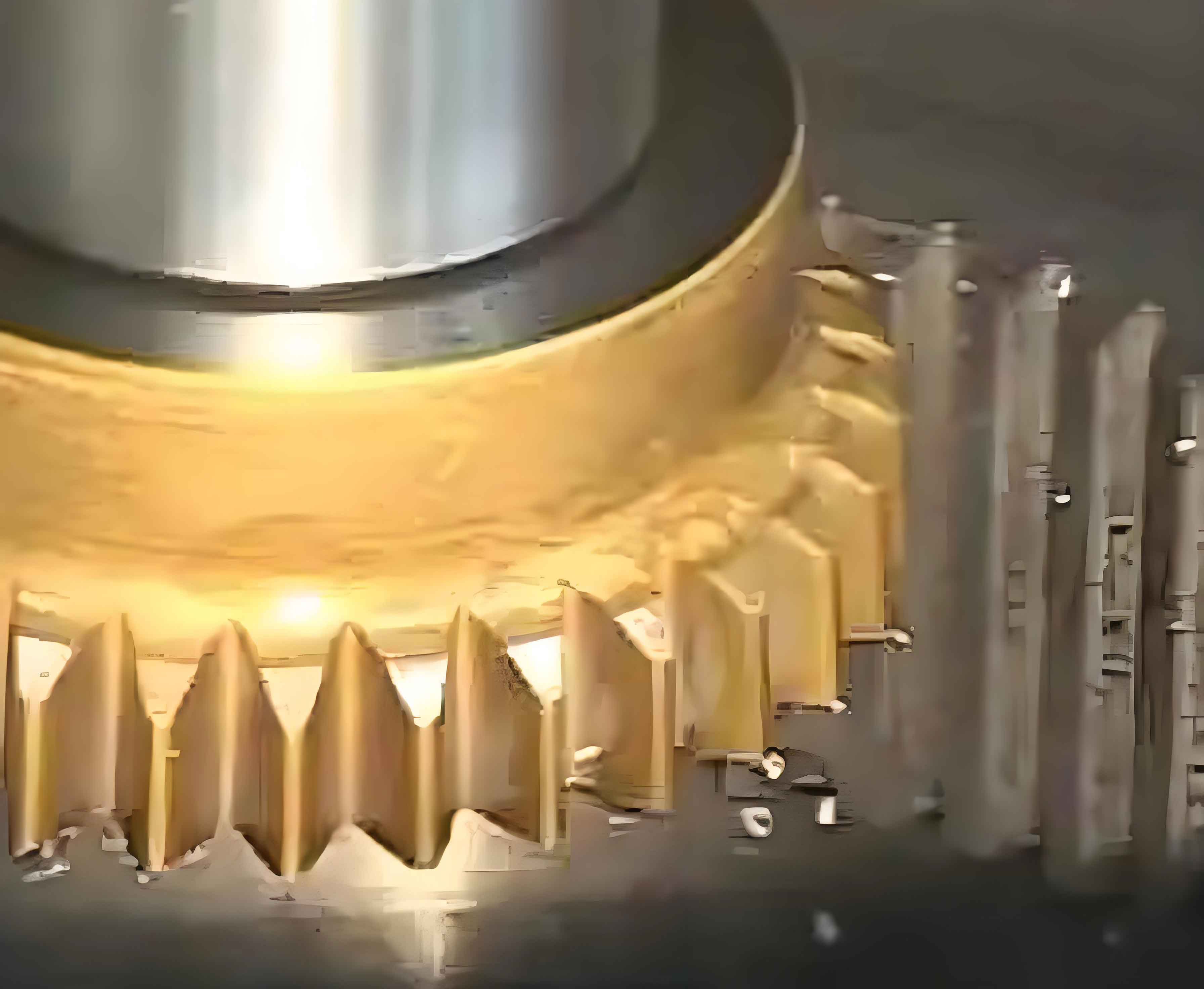

Gear shaping, a critical process for internal spline manufacturing, faces significant challenges when applied to deep blind holes with small modulus configurations. This study addresses persistent issues in gear shaping—specifically low machining quality and efficiency—through comprehensive analysis of tool structure, parameter optimization, and cutting experiments. The focus lies on minimizing tool deflection (“tool yielding”), reducing interference, lowering cutting forces, mitigating residual heat, and controlling thermal deformation in workpieces made from hardened alloys.

Introduction

Spline connections, comprising mating internal and external splines, utilize tooth flanks for centering and torque transmission. The self-centering nature of involute splines arises from radial forces during meshing, ensuring uniform load distribution across teeth and enhancing positional accuracy. These advantages make splines indispensable in high-precision mechanical transmissions like aerospace actuators. While electrical discharge machining (EDM) offers an alternative, its limitations—low efficiency, unstable tooth profile dimensions, recast layers, and fluid contamination—render it unsuitable for critical components. Consequently, gear shaping emerges as the preferred method. However, machining small-modulus internal splines within deep blind holes imposes stringent demands on machine tools, fixtures, and cutters due to inherent rigidity constraints.

Component Structure and Material Analysis

The subject component (Figure 1) features an internal spline with modulus \(m = 1\), number of teeth \(z = 12\), pressure angle \(\alpha = 30^\circ\), located at the bottom of a stepped blind hole with a depth of 64 mm. The aperture diameter is \(\varnothing 13.8 \text{ mm}\). Key specifications include:

- Radial runout \(F_r \leq 0.03 \text{ mm}\) relative to the \(\varnothing 13.8 \text{ mm}\) bore.

- Tooth alignment tolerance \(F_\beta \leq 0.019 \text{ mm}\).

- Tooth profile tolerance \(F_\alpha \leq 0.047 \text{ mm}\).

The workpiece material is 40CrNiMoA alloy steel, quenched and tempered to a hardness range of HRC 38–45. This high hardness significantly challenges gear shaping tools, especially given the depth-to-diameter ratio constraints. The small spline minor diameter (\(\varnothing 11.2 \text{ mm}\)) necessitates a slender shank tool with inherently poor rigidity, exacerbating deflection risks.

Machine Tool Selection

A Gleason GP200S CNC precision gear shaping machine was selected, offering:

- Tool spindle diameter: \(\varnothing 85 \text{ mm}\).

- Stroke adjustment range: \(3 \text{ mm} \leq s \leq 55 \text{ mm}\).

- Maximum normal module capacity: \(m_n = 5\).

- Tool interfaces: HSK and SK tapers.

- Guaranteed accuracy: DIN grade 6 or better, surface roughness \(R_a \leq 1.6 \mu \text{m}\).

This machine’s precision and rigidity make it suitable for the demanding tolerances required.

Key Challenges in Gear Shaping Deep Blind Internal Splines

- Tool Deflection (“Tool Yielding”): The long, slender tool required for the 64 mm depth experiences significant bending moments during cutting. This causes progressive tool retraction radially inward as depth increases, resulting in a tapered spline profile (larger diameter at the entrance, smaller at the bottom).

- Radial Runout (\(F_r\)) Exceeding Tolerance: Tool deflection and vibration contribute to inconsistent tooth positioning, violating the \(F_r \leq 0.03 \text{ mm}\) requirement.

- Severe Tool Wear: Initial tools (W2Mo9Cr4VCo8 HSS) deteriorated rapidly, machining only 5 parts before requiring regrinding or radial compensation (0.008–0.01 mm per part), drastically reducing efficiency.

- Thermal Deformation: High cutting forces and friction generate localized heat, causing residual thermal stress and micro-distortion in the workpiece.

Optimization Strategies

1. Tool Material Selection

Conventional high-speed steel (W2Mo9Cr4VCo8) proved inadequate for the workpiece hardness (HRC 38–45). ASP60 cobalt-enriched powder metallurgy (PM) high-speed steel was adopted, offering:

- Hardness: HRC 67–70.

- Enhanced hot hardness and compressive strength (10.5% Co content).

- Superior wear resistance and microstructural homogeneity.

- Excellent thermal stability and oxidation resistance.

The transition to ASP60 dramatically reduced flank wear and eliminated taper formation, enabling consistent machining over >25 parts per tool edge life.

2. Tool Geometry Optimization

A gear shaping cutter possesses three cutting edges per tooth: one top edge (circular arc) and two side edges (involute curves). Wear on these edges directly increases cutting forces (\(F_c\)), heat generation (\(Q\)), and temperature (\(T\)), degrading accuracy and surface finish. The rake angle (\(\gamma\)) critically influences this:

- Increasing \(\gamma\) reduces contact area and friction, lowering \(F_c\) and \(Q\):

$$F_c \propto \frac{1}{\sin \gamma}, \quad Q \propto F_c \cdot v_c$$

where \(v_c\) is cutting speed. - Higher \(\gamma\) improves surface finish (\(R_a\)) and tool life but increases tooth profile error (\(\Delta f\)) due to altered effective cutting geometry.

Standard rake angles (\(\gamma = 5^\circ \pm 5’\)) were insufficient. Experiments assessed modified rake angles (Table 1):

| Rake Angle \(\gamma\) (°) | Tool Life (parts/edge) | Profile Error \(\Delta f\) (mm) | Surface Roughness \(R_a\) (\(\mu\)m) |

|---|---|---|---|

| 5 | 5 | 0.030 | 3.2 |

| 6 | 10 | 0.035 | 3.2 |

| 7 | 20 | 0.035 | 1.6 |

| 8 | 25 | 0.040 | 1.6 |

| 9 | 15 | 0.060 | 1.6 |

A rake angle of \(\gamma = 8^\circ\) provided the optimal balance: significantly extended tool life (25 parts) and improved roughness (\(R_a = 1.6 \mu m\)), while keeping profile error (\(\Delta f = 0.040 \text{ mm}\)) within tolerance limits. Compensatory adjustments to the theoretical tooth profile angle were necessary to maintain dimensional accuracy after modifying \(\gamma\).

3. Cutting Parameter Optimization

Gear shaping involves five key parameters: number of cutting cycles (\(n_c\)), stroke speed (\(v_s\), strokes/min), radial feed rate (\(f_r\), mm/stroke), circumferential feed rate (\(f_c\), mm/stroke), and depth of cut per cycle (\(a_p\), mm). Two distinct cutting strategies were tested (Tables 2 & 3):

| Parameter | Cycle 1 | Cycle 2 | Cycle 3 |

|---|---|---|---|

| Stroke Speed \(v_s\) (strokes/min) | 140 | 160 | 180 |

| Radial Feed \(f_r\) (mm/stroke) | 0.020 | 0.010 | 0.005 |

| Circumferential Feed \(f_c\) (mm/stroke) | 0.050 | 0.030 | 0.020 |

| Depth of Cut \(a_p\) (mm) | 0.6 | 0.5 | 0.2 |

| Table Rotation Angle \(\theta\) (°) | 360 | 360 | 720 |

| Results: Severe tool wear after 5 parts; required radial compensation and additional finishing passes; Surface roughness \(R_a = 1.6-3.2 \mu m\); Cycle time per part = 40 min; Taper and runout issues persisted. | |||

| Parameter | Cycle 1 | Cycle 2 | Cycle 3 |

|---|---|---|---|

| Stroke Speed \(v_s\) (strokes/min) | 140 | 160 | 180 |

| Radial Feed \(f_r\) (mm/stroke) | 0.004 | 0.003 | 0.001 |

| Circumferential Feed \(f_c\) (mm/stroke) | 0.120 | 0.080 | 0.050 |

| Depth of Cut \(a_p\) (mm) | 0.6 | 0.5 | 0.2 |

| Table Rotation Angle \(\theta\) (°) | 360 | 360 | 720 |

| Results: 25 parts machined consecutively without tool compensation; All splines passed gauge inspection; Surface roughness \(R_a = 1.6 \mu m\); Cycle time per part = 25 min; Minimal taper, runout \(F_r \leq 0.03 \text{ mm}\) achieved. | |||

Strategy 2 implements a High-Speed Machining (HSM) principle: High circumferential feed (\(f_c\)) + Low radial feed (\(f_r\)) + High stroke speed (\(v_s\)). This approach yields significant advantages in gear shaping deep splines:

- Reduced Cutting Force & Heat: Smaller radial engagement (\(f_r\)) lowers instantaneous cutting force \(F_c\):

$$F_c \approx k_c \cdot b \cdot h_m$$

where \(k_c\) is specific cutting force, \(b\) is chip width, \(h_m\) is mean chip thickness (proportional to \(f_r\)). Lower \(F_c\) directly reduces friction heat \(Q\):

$$Q \propto F_c \cdot v_c$$

Minimizing \(Q\) curtails workpiece thermal expansion and residual stress. - Improved Surface Finish & Tool Life: Higher \(v_s\) and \(f_c\) distribute wear over a larger tool edge length. The minimal \(f_r\) ensures uniform, thin chips, preventing localized high-stress zones on the cutting edge.

- Vibration Suppression: Reduced \(F_c\) fluctuations diminish low-frequency chatter, enhancing surface integrity and geometric accuracy.

- Enhanced Efficiency: Increased \(v_s\) and optimized cycle structure reduced machining time by 37.5%.

Conclusions

This research successfully optimized the gear shaping process for challenging deep blind hole, small-modulus internal splines in hardened 40CrNiMoA. Key outcomes include:

- Tool Material: ASP60 PM-HSS significantly outperformed conventional HSS, providing the necessary hot hardness and wear resistance for machining at HRC 38–45, extending tool life 5-fold.

- Tool Geometry: Increasing the rake angle to \(\gamma = 8^\circ\) effectively reduced cutting forces and heat generation while maintaining acceptable profile error (\(\Delta f = 0.040 \text{ mm}\)). Compensatory profile grinding was essential.

- Cutting Strategy: The HSM-inspired approach—characterized by high stroke speed (\(v_s\)), high circumferential feed (\(f_c\)), and low radial feed (\(f_r\))—proved superior. It minimized cutting forces (\(F_c\)), residual heat (\(Q\)), and thermal distortion, while suppressing vibration and tool deflection. This strategy ensured consistent part quality (runout \(F_r \leq 0.03 \text{ mm}\), roughness \(R_a = 1.6 \mu m\)) and boosted efficiency (cycle time reduced from 40 min to 25 min).

- Rigidity Enhancement: Maximizing tool shank diameter (\(\varnothing 7.5 \text{ mm} \rightarrow \varnothing 9.5 \text{ mm}\)) within the 36 mm entry bore section directly countered tool yielding.

These optimizations collectively resolved the core challenges of tool yielding, taper formation, excessive runout, rapid tool wear, and thermal deformation inherent in deep blind hole gear shaping. The validated parameters and tool design principles provide a robust framework for machining similar high-precision, high-hardness internal splines, enhancing productivity and reducing manufacturing costs across aerospace and precision engineering applications. Future work should explore the impact of tool coatings (e.g., AlTiN) and advanced coolant strategies to further push the boundaries of deep hole gear shaping performance.