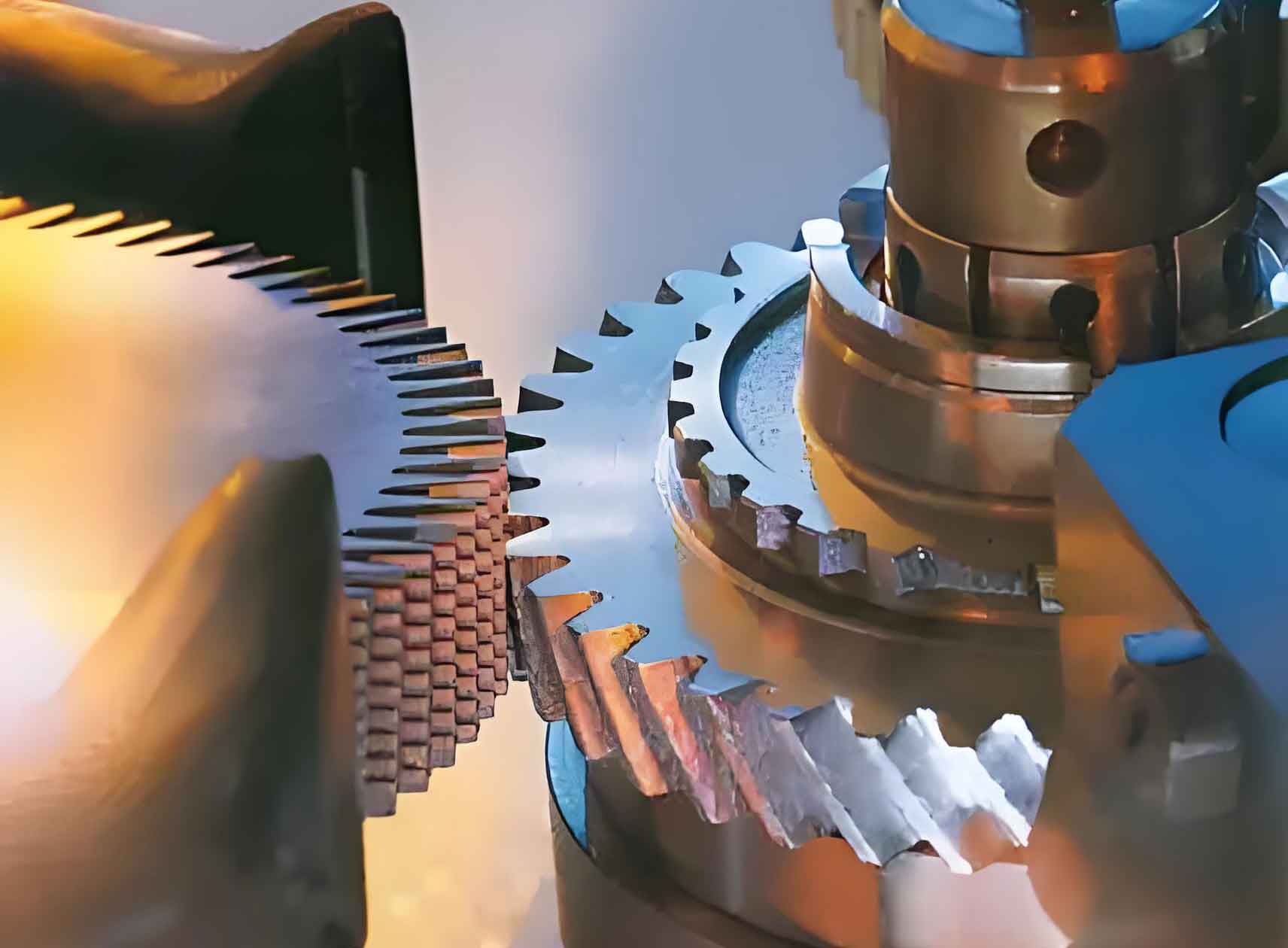

Gear shaving is a critical finishing process in gear manufacturing, offering advantages over grinding such as higher productivity, lower cost, and radial error correction. However, when using standard involute shaving cutters, a mid-concave error often appears near the pitch point of the workpiece tooth profile. This phenomenon is particularly pronounced when processing gears with large modules and low tooth counts, severely impacting transmission quality. This study systematically investigates the formation mechanism of mid-concave errors and proposes effective countermeasures through theoretical modeling, finite element analysis (FEA), and experimental validation.

Formation Mechanism of Gear Shaving Mid-Concave Error

Gear shaving operates on the principle of crossed helical gear pair spatial meshing. The meshing process is governed by the equation derived from spatial kinematics:

$$ \mathbf{v}^{(12)} \cdot \mathbf{n} = 0 $$

where \(\mathbf{v}^{(12)}\) is the relative velocity vector and \(\mathbf{n}\) is the normal vector at the contact point. The contact trajectory on the shaving cutter surface is expressed parametrically as:

$$

\begin{cases}

x_{\Gamma_1} = r_{b1} \left[ \cos(\theta_1 – \lambda_1 – \gamma_1) + \theta_1 \sin(\theta_1 – \lambda_1 – \gamma_1) \right] \\

y_{\Gamma_1} = r_{b1} \left[ \sin(\theta_1 – \lambda_1 – \gamma_1) – \theta_1 \cos(\theta_1 – \lambda_1 – \gamma_1) \right] \\

z_{\Gamma_1} = p_1 \lambda_1

\end{cases}

$$

Three primary factors contribute to mid-concave errors:

1. Relative Velocity Variation: The tangential component of relative velocity (\(v_{\tau}^{(12)}\)) approaches zero near the pitch point, extending cutting time and increasing material removal:

$$ v_{\tau}^{(12)} = \omega_1 \left[ (\gamma_1 – \theta_1 – \lambda_1) \left( r_{b1} \cos(\theta_1 – \lambda_1 – \gamma_1) + r_{b1} \theta_1 \sin(\theta_1 – \lambda_1 – \gamma_1) \right) \right] + \cdots $$

2. Induced Normal Curvature: The induced curvature \(k^{(12)}\) in the direction perpendicular to the cutting edge minimizes near the pitch point, enhancing surface conformity and cutting efficiency:

$$ k^{(12)} = k_{\alpha}^{(1)} – k_{\alpha}^{(2)} = -\frac{p_1}{r_{b1}^2 \theta_1^2 + p_1^2} – \left( k_2^{(2)} \cos^2 \sigma + k_1^{(2)} \sin^2 \sigma \right) $$

3. Dynamic Load Distribution: Contact point variation (2, 3, or 4 simultaneous contacts) creates load imbalance. Pitch point regions experience 2-point contact with doubled force per contact point versus 4-point zones:

| Contact Points | Force per Point (N) | Location |

|---|---|---|

| 2 | 750 | Pitch region |

| 3 | 500 | Transitional zones |

| 4 | 375 | Tip/root regions |

Finite Element Contact Analysis of Gear Shaving

Parametric 3D models of shaving cutter and workpiece gear were developed using UG NX. FEA in ANSYS analyzed stress distributions under 1,500N radial force at different meshing positions:

Stress results for different contact scenarios:

| Contact Points | Max Stress (MPa) | Deformation (μm) |

|---|---|---|

| 2-point | 855.0 | 12.3 |

| 3-point | 545.1 | 8.2 |

| 4-point | 498.2 | 6.7 |

Higher stresses in 2-point contact regions correlate with increased material removal at the pitch point, directly validating the load distribution mechanism.

Negative Modified Gear Shaving and Balance Shaving

Negative Modification: Applying negative profile shift (\(x_{n1} < 0\)) reduces the working pressure angle (\(\alpha’_{t1}\)), shifting the pitch point toward the root where load is distributed across multiple teeth. The modification range is bounded by:

$$ \alpha’_{t1,\min} = 13.52^\circ, \quad \alpha’_{t1,\max} = 19.40^\circ \quad \Rightarrow \quad x_{n1} \in [-1.745, -0.657] $$

Experimental results demonstrate reduced mid-concave errors with increased negative shift:

| Modification (\(x_{n1}\)) | Mid-Concave Depth (μm) |

|---|---|

| 0 | 18.5 |

| -0.676 | 9.2 |

| -0.857 | 5.1 |

Balance Shaving: Ensures equal contact points on both flanks by satisfying geometric conditions. For simultaneous engagement:

$$ \tan\alpha’_{t1} \sin\beta_{b1} + \cos\beta_{b1} = \frac{\rho_{a1} + \rho_{c1}}{2 r_{b1}} $$

Optimal negative shift (\(x_{n1} = -0.764\)) achieves balanced contact, reducing mid-concave depth by 60% versus standard gear shaving.

Gear Shaving Cutter Modification

Tool modification compensates for mid-concave errors by introducing a reverse profile on the cutter. Total workpiece deformation (\(\delta_z\)) combines Hertzian contact deformation (\(\delta_e\)) and bending deformation (\(\delta_w\)):

$$ \delta_z = \delta_e \pm \delta_w = \frac{3}{2a} \mathcal{K}(e) P (\kappa_1 + \kappa_2) \pm \sum_{i=1}^n \delta_{wi} $$

Radial force significantly influences deformation magnitude:

| Radial Force (N) | Max \(\delta_z\) (μm) |

|---|---|

| 750 | 6.1 |

| 1,200 | 8.3 |

| 1,600 | 10.2 |

| 2,000 | 12.4 |

Deformation data is fitted to polynomial curves for CNC shaving cutter grinding (e.g., SRS410 machines). Cubic fitting provides optimal accuracy:

$$ \delta_{\text{fit}} = 0.24 – 1.85\theta + 4.27\theta^2 – 2.96\theta^3 \quad (R^2 = 0.992) $$

Conclusions and Future Work

Mid-concave errors in gear shaving originate from velocity, curvature, and load factors, with 2-point contact regions exhibiting 70% higher stress than 4-point zones. Negative modification (\(x_{n1} \leq -0.65\)) and balance shaving reduce errors by over 50%. Tool modification based on deformation polynomials provides precise compensation. Future work will optimize multi-point FEA and refine deformation models for complex gear shaving applications.